LECTURE ¹ 4

SENSORS AND

SIGNAL PROCESSING. DISPLACEMENT, POSITION AND PROXIMITY SENSORS

4.1. EDDY CURRENT

PROXIMITY SENSORS

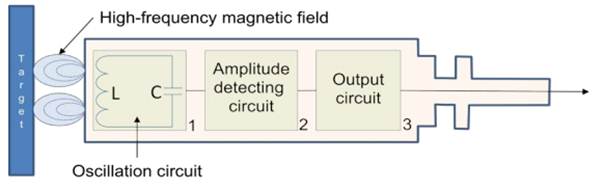

Eddy current proximity

sensors are used to detect non-magnetic but conductive materials. They comprise

of a coil, an oscillator, a detector and a triggering circuit. Figure 4.1.1

shows the construction of eddy current proximity switch.

When an alternating current

is passed thru this coil, an alternative magnetic field is generated. If a

metal object comes in the close proximity of the coil, then eddy currents are

induced in the object due to the magnetic field. These eddy currents create

their own magnetic field which distorts the magnetic field responsible for

their generation. As a result, impedance of the coil changes and so the amplitude

of alternating current. This can be used to trigger a switch at some

pre-determined level of change in current.

Eddy current sensors are

relatively inexpensive, available in small in size, highly reliable and have

high sensitivity for small displacements.

Fig. 4.1.1. Schematic of

Inductive Proximity Sensor

Applications of eddy current

proximity sensors:

·

automation

requiring precise location;

·

machine tool

monitoring;

·

final assembly

of precision equipment such as disk drives;

·

measuring the dynamics

of a continuously moving target, such as a vibrating element;

·

drive shaft

monitoring;

·

vibration

measurements.

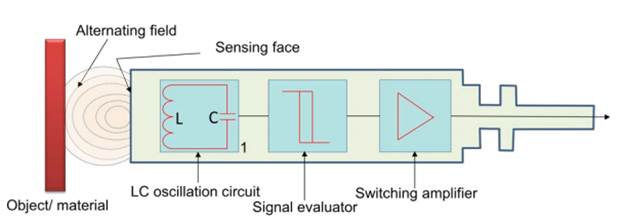

Inductive

proximity switch

Inductive proximity switches

are basically used for detection of metallic objects. Figure 4.1.2 shows the

construction of inductive proximity switch. An inductive proximity sensor has

four components; the coil, oscillator, detection circuit and output circuit. An

alternating current is supplied to the coil which generates a magnetic field.

When, a metal object comes closer to the end of the coil,

inductance of the coil changes. This is continuously monitored by a circuit

which triggers a switch when a preset value of inductance change is occurred.

Fig. 4.1.2. Schematic of Inductive Proximity Switch

Applications of inductive

proximity switches:

·

Industrial

automation: counting of products during production or transfer;

·

Security:

detection of metal objects, arms, land mines.

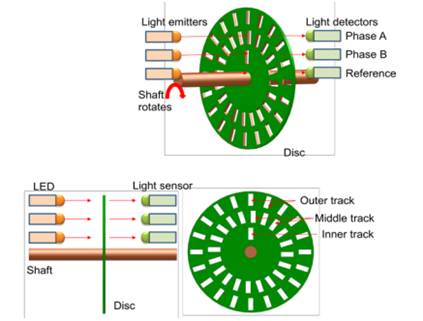

Optical encoders

Optical

encoders provide digital output as a result of linear / angular displacement.

These are widely used in the Servo motors to measure the rotation of shafts.

Figure 4.1.3 shows the construction of an optical encoder.

Fig. 4.1.3. Construction

and working of optical encoder

It

comprises of a disc with three concentric tracks of equally spaced holes. Three

light sensors are employed to detect the light passing thru the holes. These

sensors produce electric pulses which give the angular displacement of the

mechanical element e.g. shaft on which the Optical encoder is mounted. The

inner track has just one hole which is used locate the «home» position of the disc. The holes on the middle track offset from the

holes of the outer track by one-half of the width of the hole. This arrangement

provides the direction of rotation to be determined. When the disc rotates in

clockwise direction, the pulses in the outer track lead those in the inner; in

counter clockwise direction they lag behind. The resolution can be determined

by the number of holes on disc. With 100 holes in one revolution, the

resolution would be:

360⁰/100 = 3.6⁰.

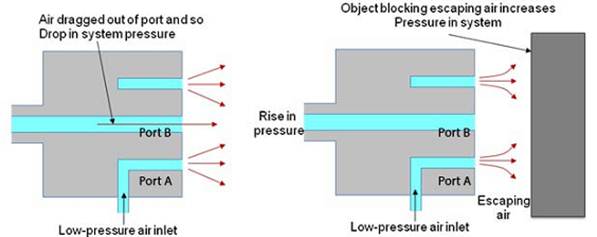

Pneumatic

Sensors

Fig. 4.1.4. Working of

Pneumatic Sensors

Pneumatic sensors are used

to measure the displacement as well as to sense the proximity of an object

close to it. The displacement and proximity are transformed into change in air

pressure. Figure 4.1.4 shows a schematic of construction and working of such a

sensor. It comprises of three ports. Low pressure air is allowed to escape

through port A. In the absence of any obstacle / object, this low pressure air

escapes and in doing so, reduces the pressure in the port B. However when an

object obstructs the low pressure air (Port A), there is rise in pressure in

output port B. This rise in pressure is calibrated to measure the displacement

or to trigger a switch. These sensors are used in robotics, pneumatics and for

tooling in CNC machine tools.

Proximity

Switches

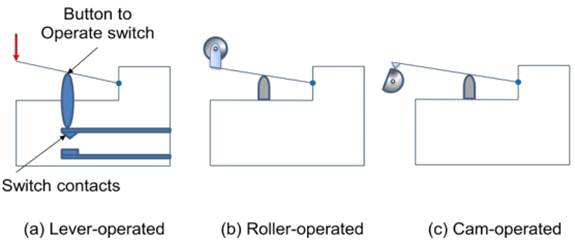

Fig. 4.1.5. Configurations

of contact type proximity switch

Figure 4.1.5 shows a number

of configurations of contact-type proximity switch being used in manufacturing

automation. These are small electrical switches which require physical contact

and a small operating force to close the contacts.They are basically employed

on conveyor systems to detect the presence of an item on the conveyor belt.

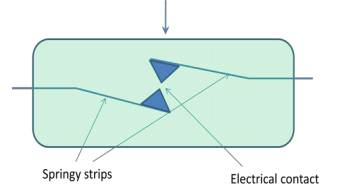

Fig. 4.1.6. Reed Switch

Magnet based Reed switches

are used as proximity switches. When a magnet attached to an object brought

close to the switch, the magnetic reeds attract to each other and close the

switch contacts. A schematic is shown in Figure 4.1.6.

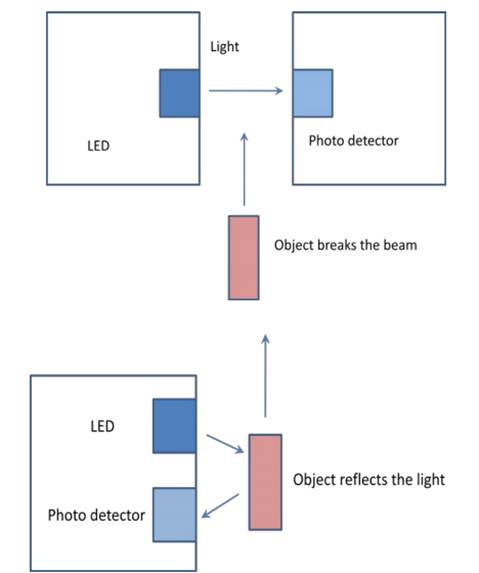

Fig. 4.1.7. LED based

proximity sensors

Photo emitting devices such

as Light emitting diodes (LEDs) and photosensitive devices such as photo diodes

and photo transistors are used in combination to work as proximity sensing

devices. Figure 4.1.7 shows two typical arrangements of LEDs and photo diodes

to detect the objects breaking the beam and reflecting light.

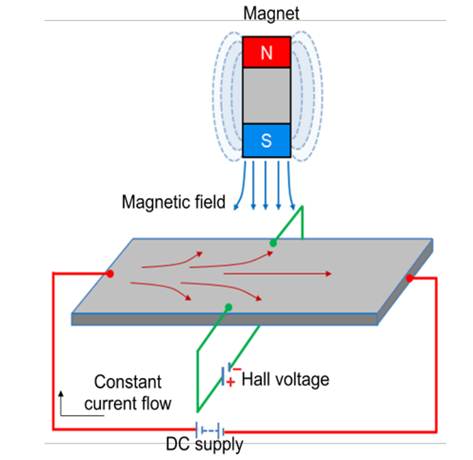

Hall effect

sensor

Figure 4.1.8 shows the

principle of working of Hall effect sensor. Hall effect sensors work on the

principle that when a beam of charge particles passes through a magnetic field,

forces act on the particles and the current beam is deflected from its straight

line path. Thus one side of the disc will become negatively charged and the

other side will be of positive charge. This charge separation generates a potential

difference which is the measure of distance of magnetic field from the disc

carrying current.

Fig. 4.1.8. Principle of

working of Hall effect sensor

The typical application of

Hall effect sensor is the measurement of fluid level in a container. The

container comprises of a float with a permanent magnet attached at its top. An

electric circuit with a current carrying disc is mounted in the casing.

When the fluid level

increases, the magnet will come close to the disc and a potential difference

generates. This voltage triggers a switch to stop the fluid to come inside the

container.

These sensors are used for

the measurement of displacement and the detection of position of an object.

Hall effect sensors need necessary

signal conditioning circuitry. They can be operated at 100 kHz. Their

non-contact nature of operation, good immunity to environment contaminants and ability to sustain in severe conditions

make them quite popular in industrial automation.

1.1.

VELOCITY, MOTION, FORCE AND PRESSURE SENSORS

Tachogenerator

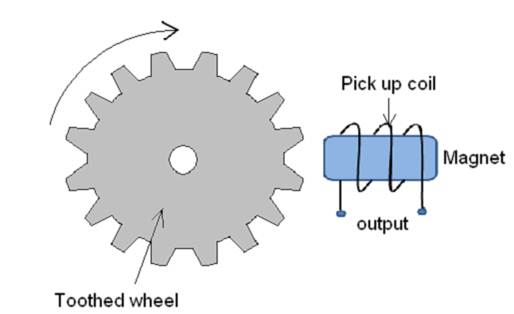

Tachogenerator works on the

principle of variable reluctance. It consists of an assembly of a toothed wheel

and a magnetic circuit as shown in figure 4.2.1. Toothed wheel is mounted on

the shaft or the element of which angular motion is to be measured. Magnetic

circuit comprising of a coil wound on a ferromagnetic material core. As the

wheel rotates, the air gap between wheel tooth and magnetic core changes which

results in cyclic change in flux linked with the coil. The alternating emf generated

is the measure of angular motion. A pulse shaping signal conditioner is used to

transform the output into a number of pulses which can be counted by a counter.

Fig. 4.2.1. Principle of

working of Techogenerator

Fig. 4.2.2. Construction and

working of AC generator

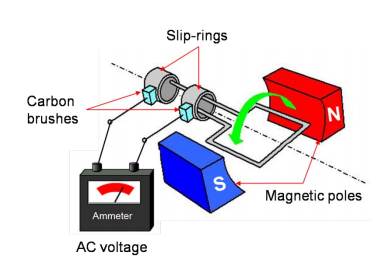

An alternating current (AC)

generator can also be used as a

techognerator. It comprises of rotor coil which rotates with the shaft. Figure

2.4.2 shows the schematic of AC generator. The rotor rotates in the magnetic

field produced by a stationary permanent magnet or electromagnet. During this

process, an alternating emf is produced which is the measure of the angular

velocity of the rotor. In general, these sensors exhibit nonlinearity error of

about ± 0.15% and are employed for the rotationsup to about 10000 rev/min.

Pyroelectric sensors

Fig. 4.2.3. Principle of

pyroelectricity

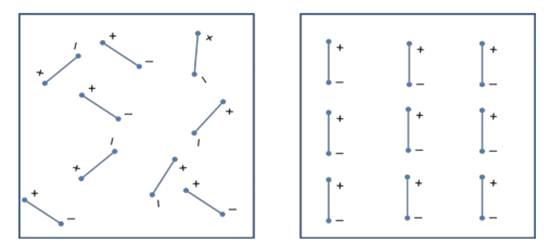

These sensors work on the

principle of pyroelectricity, which states that a crystal material such as

Lithium tantalite generates charge in

response to heat flow. In presence of an

electric field, when such a crystal material heats up, its electrical dipoles

line up as shown in figure 4.2.3. This is called as polarization. On cooling,

the material retains its polarization. In absence of electric field, when this

polarized material is subjected to infra red irradiation, its polarization

reduces. This phenomenon is the measure of detection of movement of an object.

Fig. 4.2.4. Construction and

working a Pyroelectric sensor

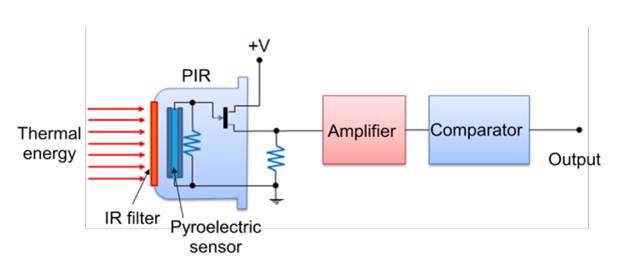

Pyroelectric sensor comprises

of a thick element of polarized material coated with thin film electrodes on

opposite faces as shown in figure 4.2.4. Initially the electrodes are in

electrical equilibrium with the polarized material. On incident of infra red,

the material heats up and reduces its polarization. This leads to charge

imbalance at the interface of crystal and electrodes. To balance this disequilibrium, measurement circuit supplies

the charge, which is calibrated against the detection of an object or its

movement.

Applications of Pyroelectric

sensors:

·

Intrusion

detector;

·

Optothermal

detector;

·

Pollution

detector;

·

Position sensor;

·

Solar cell

studies;

·

Engine analysis.

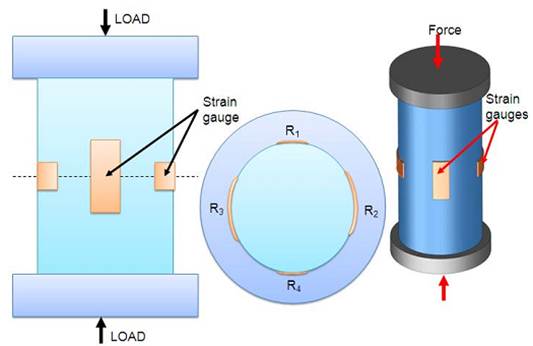

Strain Gauge as

force Sensor

Fig. 4.2.5. Strain gauge

based Load cell

Strain gauge based sensors

work on the principle of change in electrical resistance. When, a mechanical

element subjects to a tension or a compression the electric resistance of the

material changes. This is used to measure the force acted upon the element.

Figure 4.2.5 shows a strain gauge load cell. It comprises of

cylindrical tube to which strain gauges are attached. A load applied on the top

collar of the cylinder compress the strain gauge element which changes its

electrical resistance. Generally strain gauges are used to measure forces up to

10 MN. The non-linearity and repeatability errors of this transducer are ±0.03%

and ±0.02% respectively.

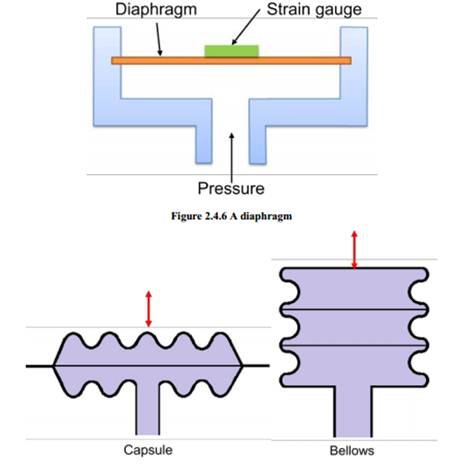

Fluid pressure

Chemical, petroleum, power

industry often need to monitor fluid pressure. Various types of instruments

such as diaphragms, capsules, and bellows are used to monitor the fluid

pressure. Specially designed strain gauges doped in diaphragms are generally

used to measure the inlet manifold pressure in applications such as

automobiles. A typical arrangement of strain gauges on a diaphragm is shown in

figure 4.2.6. Application

of pressurized fluid displaces the diaphragm. This displacement is measured by

the stain gauges in terms of radial and/or lateral strains. These strain gauges

are connected to form the arms of a Wheatstone bridge.

Fig. 4.2.6. Schematic of

Capsule and Bellow

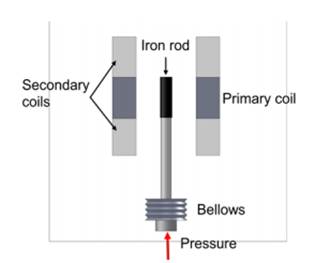

Capsule is formed by

combining two corrugated diaphragms. It has enhanced sensitivity in comparison with that of diaphragms.

Figure 2.4.7 shows a schematic of a Capsule and a Bellow. A stack of capsules

is called as «Bellows». Bellows with a LVDT sensor measures the fluid

pressure in terms of change in resultant voltage across the secondary coils of

LVDT.

Fig. 4.2.7. Bellow with a

LVDT

Figure 2.4.8 shows a typical

arrangement of the same.

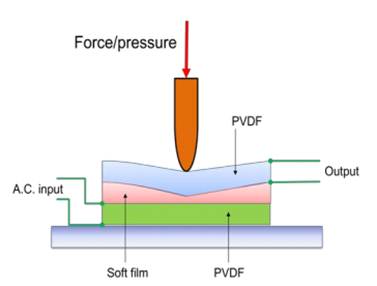

Tactile sensors

Fig. 4.2.8. Schematic of a

tactile sensor

In general, tactile sensors

are used to sense the contact of fingertips of a robot with an object. They are

also used in manufacturing of ‘touch display’ screens of visual display units

(VDUs) of CNC machine tools. Figure 2.4.9 shows the construction of piezo-electric

polyvinylidene fluoride (PVDF) based tactile sensor. It has two PVDF layers

separated by a soft film which transmits the vibrations. An alternating current

is applied to lower PVDF layer which generates vibrations due to reverse

piezoelectric effect. These vibrations are transmitted to the upper PVDF layer

via soft film. These vibrations cause alternating voltage across the upper PVDF

layer. When some pressure is applied on the upper PVDF layer the vibrations

gets affected and the output voltage changes. This triggers a switch or an

action in robots or touch displays.

Piezoelectric

sensor

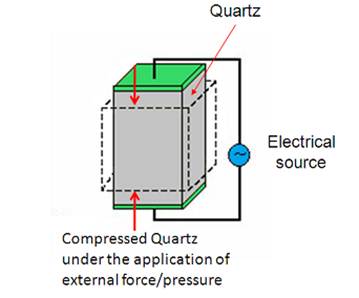

Piezoelectric sensor is used

for the measurement of pressure, acceleration and dynamic-forces such as

oscillation, impact, or high speed compression or tension. It contains

piezoelectric ionic crystal materials such as Quartz (Figure 4.2.9). On

application of force or pressure these materials get stretched or compressed.

During this process, the charge over the material changes and redistributes.

One face of the material becomes positively charged and the other negatively

charged. The net charge q on the surface is proportional to the amount x by

which the charges have been displaced. The displacement is proportion to force.

Therefore we can write:

q = kx = SF (2.2.1)

where k is constant and S is a constant termed the

charge sensitivity.

Fig. 4.2.9. Principle of

working of Piezoelectric sensor

Liquid flow

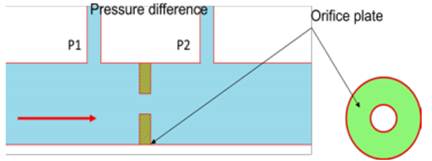

Liquid flow is generally

measured by applying the Bernoulli’s principle of fluid flow through a

constriction. The quantity of fluid flow is computed by using the pressure drop

measured. The fluid flow volume is proportional to square root of pressure

difference at the two ends of the constriction. There are various types of

fluid flow measurement devices being used in manufacturing automation such as

Orifice plate, Turbine meter etc.

Fig. 4.2.10. Orifice Plate

Figure 4.2.10 shows a

schematic of Orifice plate device. It has a disc with a hole at its center,

through which the fluid flows. The pressure difference is measured between a

point equal to the diameter of the tube upstream and a point equal to the half

the diameter downstream. Orifice plate is inexpensive and simple in

construction with no moving parts. It exhibits nonlinear behavior and does not

work with slurries. It has accuracy of ± 1.5%

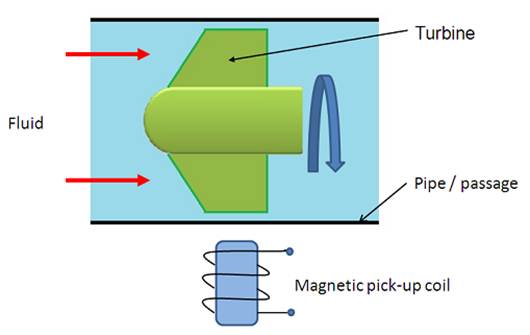

Fig. 4.2.11. Schematic of

turbine meter

Turbine flow meter has an

accuracy of ±0.3%. It has a multi blade rotor mounted centrally in the pipe

along which the flow is to be measured. Figure 4.2.11 shows the typical

arrangement of the rotor and a magnetic pick up coil. The fluid flow rotates

the rotor. Accordingly the magnetic pick up coil counts the number of magnetic

pulses generated due to the distortion of magnetic field by the rotor blades.

The angular velocity is proportional to the number of pulses and fluid flow is

proportional to angular velocity.

Fluid level

The level of liquid in a

vessel or container can be measured:

a)

directly by

monitoring the position of liquid surface;

b)

indirectly by

measuring some variable related to the height.

Direct measurements involve

the use of floats however the indirect methods employ load cells.

Potentiometers or LVDT sensors can be used along with the floats to measure the

height of fluid column. Force sensed by the load cells is proportional to the

height of fluid column.

1.2.

TEMPERATURE AND LIGHT SENSORS

Temperature conveys the

state of a mechanical system in terms of expansion or contraction of solids,

liquids or gases, change in electrical resistance of conductors, semiconductors

and thermoelectric emfs. Temperature sensors such as bimetallic strips, thermocouples,

thermistors are widely used in monitoring of manufacturing processes such as

casting, molding, metal cutting etc. The construction details and principle of

working of some of the temperature sensors are discussed in following sections.

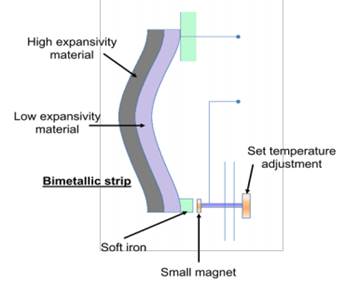

Bimetallic

strips

Fig. 4.3.1. Construction

and working of Bi-metallic strip

Bimetallic strips are used

as thermal switch in controlling the temperature or heat in a manufacturing

process or system. It contains two different metal strips bonded together. The

metals have different coefficients of expansion. On heating the strips bend

into curved strips with the metal with higher coefficient of expansion on the

outside of the curve. Figure 4.3.1 shows a typical arrangement of a bimetallic

strip used with a setting-up magnet. As the strips bend, the soft iron comes in

closer proximity of the small magnet and further touches. Then the electric

circuit completes and generates an alarm. In this way bimetallic strips help to

protect the desired application from heating above the pre-set value of

temperature.

Figure 4.3.1 shows the

construction of a RTD. It has a resistor element connected to a Wheatstone

bridge. The element and the connection leads are insulated and protected by a

sheath. A small amount of current is continuously passing though the coil. As

the temperature changes the resistance of the coil changes which is detected at

the Wheatstone bridge.

RTDs are used in the form of

thin films, wire wound or coil. They are generally made of metals such as platinum,

nickel or nickel-copper alloys. Platinum wire held by a high-temperature glass

adhesive in a ceramic tube is used to measure the temperature in a metal

furnace. Other applications are:

·

air conditioning

and refrigeration servicing;

·

food processing;

·

stoves and

grills;

·

textile

production;

·

plastics

processing;

·

petrochemical

processing;

·

micro

electronics;

·

air, gas and

liquid temperature measurement in pipes and tanks;

·

exhaust gas

temperature measurement.

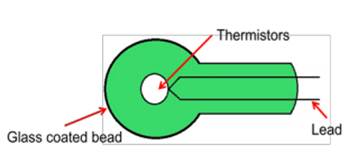

Thermistors

Thermistors follow the

principle of decrease in resistance with increasing temperature. The material

used in thermistor is generally a semiconductor material such as a sintered

metal oxide (mixtures of metal oxides, chromium, cobalt, iron, manganese and

nickel) or doped polycrystalline ceramic containing barium titanate (BaTiO3)

and other compounds. As the temperature of semiconductor material increases the number of electrons

able to move about increases which results in more current in the material and

reduced resistance. Thermistors are rugged and small in dimensions. They

exhibit nonlinear response characteristics. Thermistors are available in the

form of a bead (pressed disc), probe or chip. Figure 4.3.2 shows the

construction of a bead type thermistor. It has

a small bead of dimension from 0.5 mm to 5 mm coated with ceramic or

glass material. The bead is connected to an electric circuit through two leads.

To protect from the environment, the leads are contained in a stainless steel

tube.

Fig. 4.3.2. Schematic of a

thermistor

Applications of Thermistors:

·

To monitor the

coolant temperature and/or oil temperature inside the engine;

·

To monitor the

temperature of an incubator;

·

Thermistors are

used in modern digital thermostats;

·

To monitor the

temperature of battery packs while charging;

·

To monitor

temperature of hot ends of 3D printers;

·

To maintain

correct temperature in the food handling and processing industry;

·

Equipments;

·

To control the

operations of consumer appliances such as toasters, coffee makers, refrigerators,

freezers, hair dryers, etc.

Light sensors

A light sensor is a device

that is used to detect light. There are different types of light sensors such

as photocell/photoresistor and photo diodes being used in manufacturing and

other industrial applications. Photoresistor is also called as light dependent

resistor (LDR). It has a resistor whose resistance decreases with increasing

incident light intensity. It is made of a high resistance semiconductor

material, cadmium sulfide (CdS). The resistance of a CdS photoresistor varies

inversely to the amount of light incident upon it. Photoresistor follows the

principle of photoconductivity which results from the generation of mobile

carriers when photons are absorbed by the semiconductor material.

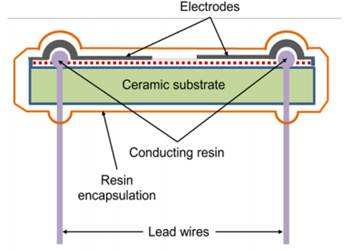

Figure 4.3.3 shows the

construction of a photo resistor. The CdS resistor coil is mounted on a ceramic

substrate. This assembly is encapsulated by a resin material. The sensitive

coil electrodes are connected to the control system though lead wires.On

incidence of high intensity light on the electrodes, the resistance of resistor

coil decreases which will be used further to generate the appropriate signal by

the microprocessor via lead wires.

Fig. 4.3.3. Construction of

a photo resistor

Photoresistors are used in

science and in almost any branch of industry for control, safety, amusement,

sound reproduction, inspection and measurement.

Applications of photo

resistor:

·

computers,

wireless phones, and televisions, use ambient light sensors to automatically control

the brightness of a screen;

·

barcode scanners

used in retailer locations work using light sensor technology;

·

in space and

robotics: for controlled and guided motions of vehicles and robots. the light sensor

enables a robot to detect light. robots can be programmed to have a specific

reaction if a certain amount of light is detected;

·

auto flash for

camera;

·

industrial

process control.

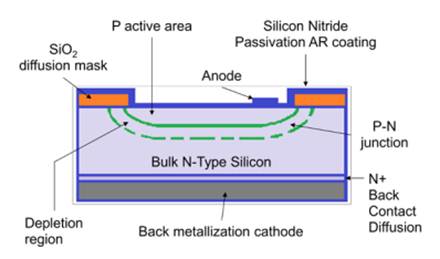

Photo diodes

Photodiode is a solid-state

device which converts incident light into an electric current. It is made of

Silicon. It consists of a shallow diffused p-n junction, normally a p-on-n

configuration. When photons of energy greater than 1.1eV (the bandgap of

silicon) fall on the device, they are absorbed and electron-hole pairs are

created. The depth at which the photons are absorbed depends upon their energy.

The lower the energy of the photons, the deeper they are absorbed. Then the

electron-hole pairs drift apart. When the minority carriers reach the junction,

they are swept across by the electric field and an electric current

establishes.

Photodiodes are one of the

types of photodetector, which convert light into either current or voltage.

These are regular semiconductor diodes except that they may be either exposed

to detect vacuum UV or X-rays or packaged with a opening or optical fiber

connection to allow light to reach the sensitive part of the device.

Fig. 4.3.4. Construction of

photo diode detector

Figure 4.3.4 shows the construction of Photo diode detector. It is

constructed from single crystal silicon wafers. It is a p-n junction device.

The upper layer is p layer. It is very thin and formed by thermal diffusion or

ion implantation of doping material such as boron. Depletion region is narrow

and is sandwiched between p layer and bulk n type layer of silicon. Light

irradiates at front surface, anode, while the back surface is cathode. The

incidence of light on anode generates a flow of electron across the p-n junction

which is the measure of light intensity.

Applications of

photo diodes

Camera: Light

Meters, Automatic Shutter Control, Auto-focus, Photographic Flash Control.

Medical: CAT

Scanners – X ray

Detection, Pulse Oximeters, Blood Particle Analyzers.

Industry:

·

Bar Code

Scanners;

·

Light Pens;

·

Brightness

Controls;

·

Encoders;

·

Position Sensors;

·

Surveying

Instruments;

·

Copiers – Density of Toner.