LECTURE №3

SENSORS

AND SIGNAL PROCESSING. SENSORS AND TRANSDUCERS

3.1.

SENSORS AND TRANSDUCERS

Measurement is an important subsystem of a

mechatronics system. Its main function is to collect the information on system

status and to feed it to the micro-processor(s)

for controlling the whole

system.

Measurement system comprises of sensors, transducers

and signal processing devices. Today a wide variety of these elements and devices are

available in the market. For a mechatronics system designer it is quite

difficult to choose suitable sensors/transducers for the desired

application(s). It is therefore essential to learn the principle of working of

commonly used sensors/transducers. A detailed consideration of the full range

of measurement technologies is, however, out of the scope of this

course. Readers are advised

to refer «Sensors

for mechatronics» by Paul P.L. Regtien, Elsevier, 2012 for more

information.

Sensors in manufacturing are basically employed to

automatically carry out the production operations as well as process monitoring

activities. Sensor technology has the following important advantages in

transforming a conventional manufacturing unit into a modern one:

1.

Sensors alarm

the system operators about the failure of any of the sub units of manufacturing

system. It helps operators to reduce the downtime of complete manufacturing

system by carrying out the preventative measures;

2.

Reduces

requirement of skilled and experienced labors;

3.

Ultra-precision

in product quality can be achieved.

Sensor

It is defined as an element which produces signal

relating to the quantity being measured. According to the Instrument Society of

America, sensor can be defined as «A device which provides a usable output in response to

a specified measurand». Here, the output is usually an «electrical quantity» and measurand is a «physical quantity, property or condition which is to

be measured».

Thus in the case of, say, a variable inductance displacement element, the

quantity being measured is displacement and the sensor transforms an input of

displacement into a change in inductance.

Transducer

It is defined as an element when subjected to some

physical change experiences a related change

or an element which converts

a specified measurand into a usable output by using a transduction principle.

It can also be defined as a device that converts a signal from one form of

energy to another form.

A wire of Constantan alloy (copper-nickel 55-45%

alloy) can be called as a sensor because variation in mechanical displacement

(tension or compression) can be sensed as change in electric resistance. This

wire becomes a transducer with appropriate electrodes and input-output

mechanism attached to it. Thus we can say that «sensors are transducers».

Sensor/transducers specifications

Transducers or measurement systems are not perfect

systems. Mechatronics design engineer must know the capability and shortcoming

of a transducer or measurement system to properly assess its performance. There

are a number of performance related parameters of a transducer or measurement

system. These parameters are called as sensor specifications.

Sensor specifications inform the user to the about

deviations from the ideal behavior of the sensors. Following are the various

specifications of a sensor/transducer system.

1. Range

The range of a sensor indicates the limits between

which the input can vary. For example, a thermocouple for the measurement of

temperature might have a range of 25-225 °C.

2. Span

The span is difference between the maximum and minimum

values of the input. Thus, the above-mentioned thermocouple will have a span of

200 °C.

3. Error

Error is the difference between the result of the

measurement and the true value of the quantity being measured. A sensor might

give a displacement reading of 29.8 mm, when the actual displacement had been

30 mm, then the error is –0.2 mm.

4. Accuracy

The accuracy defines the closeness of the agreement

between the actual measurement result and a true value of the measurand. It is

often expressed as a percentage of the full range output or full–scale

deflection. A piezoelectric transducer

used to evaluate dynamic pressure phenomena associated with explosions,

pulsations, or dynamic pressure conditions in motors, rocket engines,

compressors, and other pressurized devices is capable to detect pressures

between 0.1 and 10,000 psig (0.7 KPa to 70 MPa). If it is specified with the

accuracy of about ±1% full scale, then the reading given can be expected to be

within ± 0.7 MPa.

5. Sensitivity

Sensitivity of a sensor is defined as the ratio of

change in output value of a sensor to the per unit change in input value that

causes the output change. For example, a general purpose thermocouple may have

a sensitivity of 41 µV/°C.

6. Nonlinearity:

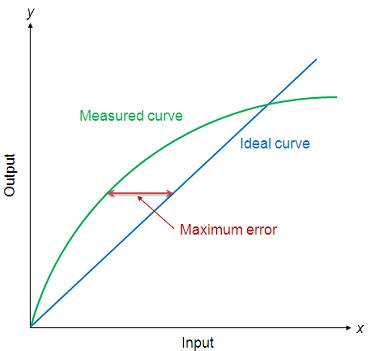

Fig. 3.1.1. Non-linearity

error

The nonlinearity indicates

the maximum deviation of the actual measured curve of a sensor from the ideal

curve. Figure 3.1.1 shows a

somewhat exaggerated relationship between the ideal, or least squares fit, line

and the actual measured or calibration line. Linearity is often specified in

terms of percentage of nonlinearity, which is defined as:

Nonlinearity (%) = Maximum

deviation in input ⁄ Maximum full scale input (3.1.1)

The static nonlinearity

defined by Equation 3.1.1 is

dependent upon environmental factors, including temperature, vibration,

acoustic noise level, and humidity. Therefore it is important to know under

what conditions the specification is valid.

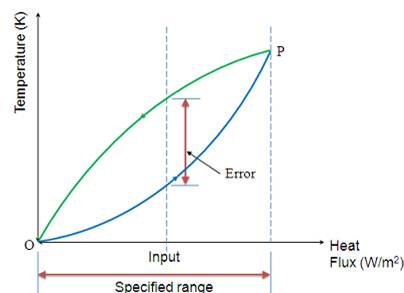

7. Hysteresis:

Fig. 3.1.2. Hysteresis

error curve

The hysteresis is an error

of a sensor, which is defined as the maximum difference in output at any

measurement value within the sensor’s specified range when approaching the

point first with increasing and then with

decreasing the input parameter. Figure 3.1.2 shows the hysteresis error

might have occurred during measurement of temperature using a thermocouple. The

hysteresis error value is normally specified as a positive or negative

percentage of the specified input range.

8. Resolution

Resolution is the smallest

detectable incremental change of input parameter that can be detected in the

output signal. Resolution can be expressed either as a proportion of the

full-scale reading or in absolute terms. For example, if a LVDT sensor measures

a displacement up to 20 mm and it provides an output as a number between 1 and

100 then the resolution of the sensor device is 0.2 mm.

9. Stability

Stability is the ability of

a sensor device to give same output when used to measure a constant input over

a period of time. The term ‘drift’ is used to indicate the change in output

that occurs over a period of time. It is expressed as the percentage of full

range output.

10. Dead band/time

The dead band or dead space

of a transducer is the range of input values for which there is no output. The

dead time of a sensor device is the time duration from the application of an

input until the output begins to respond or change.

11. Repeatability

It specifies the ability of

a sensor to give same output for repeated applications of same input value. It

is usually expressed as a percentage of the full range output: Repeatability =

(maximum – minimum values given) X 100 ⁄ full

range (3.1.2).

12. Response time

Response time describes the

speed of change in the output on a step-wise change of the measurand. It is

always specified with an indication of input step and the output range for

which the response time is defined.

Classification

of sensors

Sensors can be classified

into various groups according to the factors such as measurand, application

fields, conversion principle, energy domain of the measurand and thermodynamic

considerations. These general classifications of sensors are well described in

the references [2; 3].

Detail classification of

sensors in view of their applications in manufacturing is as follows:

a) displacement, position

and proximity sensors:

·

potentiometer;

·

strain-gauged

element;

·

capacitive

element;

·

differential

transformers;

·

eddy current

proximity sensors;

·

inductive

proximity switch;

·

optical encoders;

·

pneumatic

sensors;

·

proximity

switches (magnetic);

·

hall effect

sensors.

b) velocity and motion:

·

incremental

encoder;

·

tachogenerator;

·

pyroelectric

sensors;

c) force:

·

strain gauge

load cell.

d) fluid pressure:

·

diaphragm

pressure gauge;

·

capsules, bellows,

pressure tubes;

·

piezoelectric

sensors;

·

tactile sensor.

e) liquid flow:

·

orifice plate;

·

turbine meter.

f) liquid level:

·

floats;

·

differential

pressure.

g) temperature:

·

bimetallic

strips;

·

resistance

temperature detectors;

·

thermistors;

·

thermo-diodes

and transistors;

·

thermocouples;

·

light sensors;

·

photo diodes;

·

photo resistors;

·

photo

transistor.

3.2.

DISPLACEMENT SENSORS

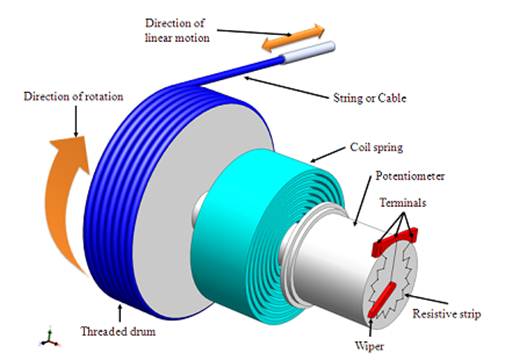

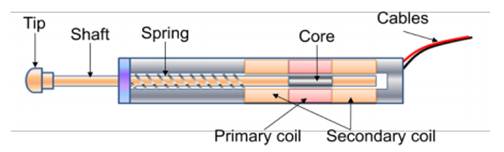

Fig. 3.2.1. Schematic of a

potentiometer sensor for measurement

of linear

displacement

Figure 2.2.1 shows the

construction of a rotary type potentiometer sensor employed to measure the

linear displacement. The potentiometer can be of linear or angular type. It

works on the principle of conversion of mechanical displacement into an

electrical signal. The sensor has a resistive element and a sliding contact

(wiper). The slider moves along this conductive body, acting as a movable

electric contact.

The object of whose

displacement is to be measured is connected to the slider by using:

·

a rotating shaft

(for angular displacement);

·

a moving rod (for

linear displacement);

·

a cable that is

kept stretched during operation.

The resistive element is a wire wound track or

conductive plastic. The track comprises of large number of closely packed turns

of a resistive wire. Conductive plastic is made up of plastic resin embedded

with the carbon powder. Wire wound track

has a resolution of the order of ± 0.01

% while the conductive plastic may have

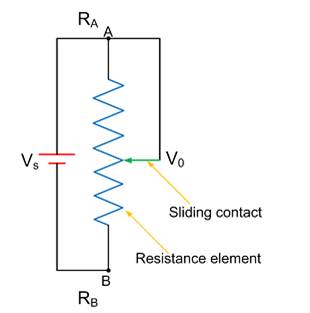

the resolution of about 0.1 µm. During the sensing operation, a voltage Vs is applied across the resistive element.

A voltage divider circuit is formed when slider comes into contact with the

wire. The output voltage (VA) is

measured as shown in the figure 3.2.2. The output voltage is proportional to

the displacement of the slider over the wire. Then the output parameter

displacement is calibrated against the output voltage VA.

Fig. 3.2.2. Potentiometer:

electric circuit

Applications of

potentiometer

These sensors are primarily

used in the control systems with a feedback loop to ensure that the moving

member or component reaches its commanded position. These are typically used on

machine-tool controls, elevators, liquid-level assemblies, forklift trucks,

automobile throttle controls. In manufacturing, these are used in control of

injection molding machines, woodworking machinery, printing, spraying,

robotics, etc. These are also used in

computer-controlled monitoring of sports equipment.

3.3.

APPLICATIONS OF CAPACITIVE ELEMENT SENSORS

Applications of capacitive

element sensors:

·

Feed hopper

level monitoring;

·

Small vessel

pump control;

·

Grease level

monitoring ;

·

Level control of

liquids.

Metrology applications:

·

to measure shape

errors in the part being produced;

·

to analyze and

optimize the rotation of spindles in various machine tools such as surface

grinders, lathes, milling machines, and air bearing spindles by measuring

errors in the machine tools themselves.

Assembly line testing:

·

to test

assembled parts for uniformity,

thickness or other design features;

·

to detect the

presence or absence of a certain component, such as glue etc.

Linear variable

differential transformer (LVDT)

Fig. 3.3.1. Construction of

a LVDT sensor

Linear variable differential

transformer (LVDT) is a primary transducer used for measurement of linear

displacement with an input range of about ± 2 to ± 400 mmin general. It has

non-linearity error ± 0.25% of full range. Figure 2.2.6 shows the construction

of a LVDT sensor. It has three coils symmetrically spaced along an insulated

tube. The central coil is primary coil and the other two are secondary coils.

Secondary coils are connected in series in such a way that their outputs oppose

each other. A magnetic core attached to the element of which displacement is to

be monitored is placed inside the insulated tube.

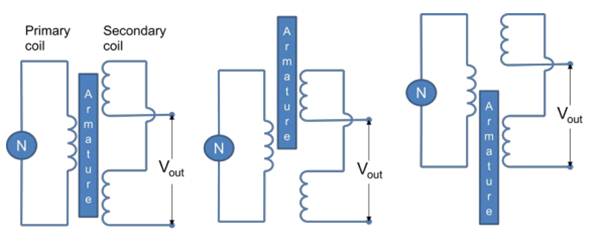

Fig. 3.3.2. Working of

LVDT sensor

Due to an alternating

voltage input to the primary coil, alternating electro-magnetic forces (emfs)

are generated in secondary coils. When the magnetic core is centrally placed

with its half portion in each of the secondary coil regions then the resultant

voltage is zero. If the core is displaced from the central position as shown in

Figure 3.3.2, say, more in secondary coil 1 than in coil 2, then more emf is

generated in one coil i.e. coil 1 than the other, and there is a resultant voltage

from the coils. If the magnetic core is further displaced, then the value of

resultant voltage increases in proportion with the displacement. With the help

of signal processing devices such as low pass filters and demodulators, precise

displacement can be measured by using LVDT sensors.

LVDT exhibits good

repeatability and reproducibility. It is generally used as an absolute position

sensor. Since there is no contact or sliding between the constituent elements

of the sensor, it is highly reliable. These sensors are completely sealed and

are widely used in Servomechanisms, automated measurement in machine tools.

A rotary variable

differential transformer (RVDT) can be used for the measurement of rotation.

Readers are suggested to prepare a report on principle of working and

construction of RVDT sensor.

Applications of

LVDT sensors

Applications of LVDT

sensors:

·

Measurement of

spool position in a wide range of servo valve applications;

·

To provide

displacement feedback for hydraulic cylinders;

·

To control weight

and thickness of medicinal products viz. tablets or pills;

·

For automatic

inspection of final dimensions of products being packed for dispatch;

·

To measure

distance between the approaching metals during Friction welding process;

·

To continuously

monitor fluid level as part of leak detection system;

·

To detect the

number of currency bills dispensed by an ATM.

In the next module we will study the various sensors,

signal conditioning devices and data conversion devices which are commonly used

in mechatronics and manufacturing automation.