LECTURE ¹ 2

MECHATRONICS: PRODUCTS AND

SYSTEMS IN MANUFACTURING

2.1. COMPUTER

NUMERICAL CONTROL (CNC) MACHINES

CNC machine is the best and

basic example of application of Mechatronics in manufacturing automation.

Efficient operation of conventional machine tools such as Lathes, milling

machines, drilling machine is dependent on operator skill and training. Also a

lot of time is consumed in workpart setting, tool setting and controlling the

process parameters viz. feed, speed, depth of cut. Thus conventional machining

is slow and expensive to meet the challenges of frequently changing

product/part shape and size.

Computer numerical control

(CNC) machines are now widely used in small to large scale industries. CNC

machine tools are integral part of Computer Aided Manufacturing (CAM) or

Computer Integrated Manufacturing (CIM) system. CNC means operating a machine tool by a series of coded

instructions consisting of numbers, letters of the alphabets, and symbols which

the machine control unit (MCU) can understand. These instructions are converted

into electrical pulses of current which the machine’s motors and controls

follow to carry out machining operations on a workpiece. Numbers, letters, and

symbols are the coded instructions which refer to specific distances,

positions, functions or motions which the machine tool can understand.

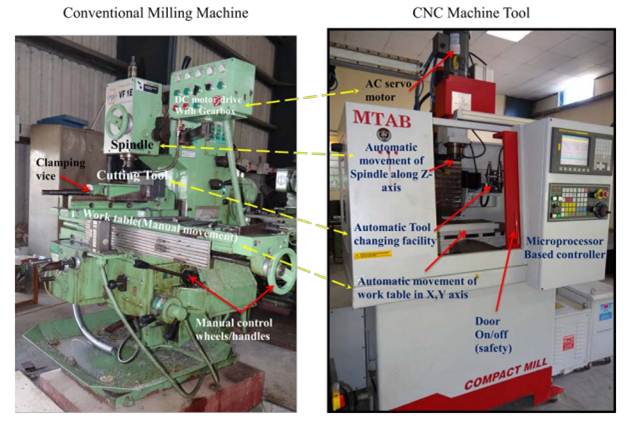

Fig. 2.1.1. Comparison

between a conventional machine tool and

a CNC machine

tool

Computer numerical control

(CNC) machines are now widely used in small to large scale industries. CNC

machine tools are integral part of Computer Aided Manufacturing (CAM) or

Computer Integrated Manufacturing (CIM) system. CNC means operating a machine tool by a series of coded

instructions consisting of numbers, letters of the alphabets, and symbols which

the machine control unit (MCU) can understand. These instructions are converted

into electrical pulses of current which the machine’s motors and controls

follow to carry out machining operations on a workpiece. Numbers, letters, and

symbols are the coded instructions which refer to specific distances,

positions, functions or motions which the machine tool can understand.

CNC automatically guides the

axial movements of machine tools with the help of computers. The auxiliary

operations such as coolant on-off, tool change, door open-close are automated

with the help of micro-controllers. Figure 1.2.1 shows the fundamental

differences between a conventional and a CNC machine tool. Manual operation of

table and spindle movements is automated by using a CNC controllers and servo

motors. The spindle speed and work feed can precisely be controlled and

maintained at programmed level by the controller. The controller has self

diagnostics facility which regularly alarms the operator in case of any safety

norm violation viz. door open during machining, tool wear/breakage etc. Modern

machine tools are now equipped with friction-less drives such as re-circulating

ball screw drives, Linear motors etc. The detail study of various elements of

such a Mechatronics based system is the primary aim of this course and these

are described at length in the next modules.

2.2. TOOL

MONITORING SYSTEMS

Uninterrupted machining is

one of the challenges in front manufacturers to meet the production goals and

customer satisfaction in terms of product quality. Tool wear is a critical

factor which affects the productivity of a machining operation. Complete automation

of a machining process realizes when there is a successful prediction of tool

(wear) state during the course of machining operation. Mechatronics based cutting tool-wear

condition monitoring system is an integral part of automated tool rooms and unmanned

factories. These systems predict the tool wear and give alarms to the system

operator to prevent any damage to the machine tool and workpiece. Therefore it

is essential to know how the mechatronics is helping in monitoring the tool

wear. Tool wear can be observed in avariety of ways. These can be classified in

two groups (Table 2.2.1).

Table 2.2.1

Tool monitoring systems

|

Direct methods |

Indirect

methods |

|

Electrical resistance |

Torque and power |

|

Optical measurements |

Temperature |

|

Machining hours |

Vibration and acoustic emission |

|

Contact sensing |

Cutting forces and strain measurements |

Direct methods deal with the

application of various sensing and measurement instruments such as micro-scope,

machine/camera vision; radioactive techniques to measure the tool wear. The

used or worn-out cutting tools will be taken to the metrology or inspection

section of the tool room or shop floor where they will be examined by using one

of direct methods. However, these methods can easily be applied in practice when

the cutting tool is not in contact with the work piece. Therefore they are

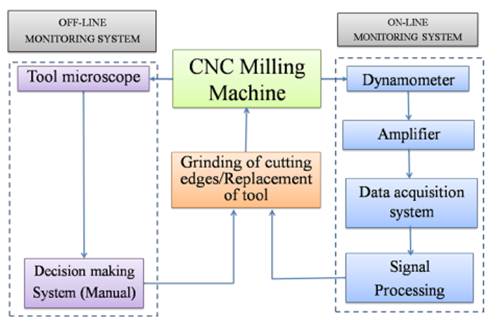

called as offline tool monitoring system. Figure 2.2.1 shows a schematic of

tool edge grinding or replacement scheme based on the measurement carried out

using offline tool monitoring system. Offline methods are time consuming and

difficult to employ during the course of an actual machining operation at the

shop floor.

Indirect methods predict the condition of the cutting

tool by analyzing the relationship between cutting conditions and response of

machining process as a measurable quantity through sensor signals output such

as force, acoustic emission, vibration, or current.

Fig. 2.2.1. Off-line and

on-line tool monitoring system for tool edge grinding

Figure 2.2.1 shows a typical example of an on-line

tool monitoring system. It employs the cutting forces recoded during the

real-time cutting operation to predict the tool-wear. The cutting forces can be

sensed by using either piezo-electric or strain gaugebased force transducer. A micro-processor

based control system continuously monitors «conditioned» signals received from

the Data Acquisition System (DAS). It is generally programmed/trained with the

past recorded empirical data for a wide range of process conditions for a

variety of materials. Artificial Intelligence (AI) tools such as Artificial

Neural Network (ANN), Genetic Algorithm (GA) are used to train the

microprocessor based system on a regular basis. Based on this training the

control system takes the decision to change the tool or gives an alarm to the

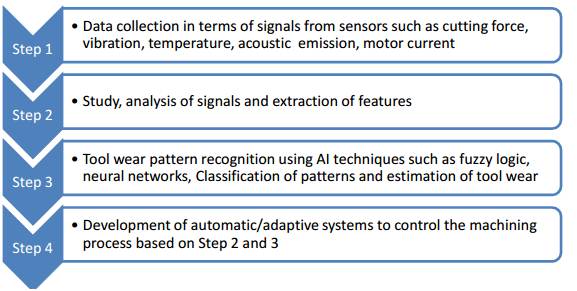

operator. Various steps followed in On-line approach to measure the tool wear

and to take the appropriate action are shown in Figure 2.2.3.

A lot of academic as well as industrial research has

been carried out on numerical and experimental studies of design, development

and analysis of «Tool Condition Monitoring Systems». Readers are suggested to

browse various international journals such as International Journal of Advanced

Manufacturing Technology (Springer), International Journal of Machine Tool and

Manufacture; International Journal of Materials Processing Technology

(Elsevier), etc. to learn more about these techniques.

Fig. 2.2.3. Steps followed

in an indirect tool monitoring system

Nowadays customers are

demanding a wide variety of products. To satisfy this demand, the manufacturers

«production» concept has moved away from «mass» to small «batch» type of

production. Batch production offers more flexibility in product manufacturing.

To cater this need, Flexible Manufacturing Systems (FMS) have been evolved.

As per Rao, P.N. [3], FMS

combines microelectronics and mechanical engineering to bring the economies of

the scale to batch work. A central online computer controls the machine tools,

other work stations, and the transfer of components and tooling.

The computer also provides

monitoring and information control. This combination of flexibility and overall

control makes possible the production of a wide range of products in small

numbers. FMS is a manufacturing cell or system consisting of one or more CNC

machines, connected by automated material handling system, pick-and-place

robots and all operated under the control of a central computer. It also has

auxiliary sub-systems like component load/unload station, automatic tool

handling system, tool pre-setter, component measuring station, wash station

etc. Figure 2.2.4 shows a typical arrangement of FMS system and its

constituents. Each of these will have further elements depending upon the

requirement as given below.

A. Workstations

·

CNC machine

tools

·

Assembly

equipment

·

Measuring

Equipment

·

Washing stations

B. Material handing Equipment

·

Load unload

stations (Palletizing)

·

Robotics

·

Automated Guided

Vehicles (AGVs)

·

Automated

Storage and retrieval Systems (AS/RS)

C. Tool systems

·

Tool setting

stations

·

Tool transport

systems

D. Control system

·

Monitoring

equipments

·

Networks

It can be noticed that the

FMS is shown with two machining centers viz. milling center and turning center.

Besides it has the load/unload stations, AS/RS for part and raw material

storage, and a wire guided AGV for transporting the parts between various

elements of the FMS. This system is fully automatic means it has automatic tool

changing (ATC) and automatic pallet changing (APC) facilities. The central

computer controls the overall operation and coordination amongst the various

constituents of the FMS system. Video attached herewith gives an overview of a

FMS system.

Fig. 2.2.4. A FMS Setup

The characteristic features

of an FMS system are as follows:

1.

FMS solves the

mid-variety and mid-volume production problems for which neither the high

production rate transfer lines nor the highly flexible stand-alone CNC machines

are suitable;

2.

Several types of

a defined mix can be processed simultaneously;

3.

Tool change-over

time is negligible;

4.

Part handling

from machine to machine is easier and faster due to employment of computer

controlled material handling system.

Benefits of an FMS:

·

Flexibility to

change part variety

·

Higher

productivity

·

Higher machine

utilization

·

Less rejections

·

High product

quality

·

Reduced

work-in-process and inventory

·

Better control

over production

·

Just-in-time

manufacturing

·

Minimally manned

operation

·

Easier to expand

2.3.

COMPUTER

INTEGRATED MANUFACTURING (CIM)

In the last lecture, we have

seen that a number of activities and operations viz. designing, analyzing,

testing, manufacturing, packaging, quality control, etc. are involved in the

life cycle of a product or a system (see Figure 1.1.4). Application of principles of

automation to each of these activities enhances the productivity only at the

individual level. These are termed as «islands of automation». Integrating all these islands of automation into a

single system enhances the overall productivity. Such a system is called as «Computer Integrated Manufacturing (CIM)».

The Society of Manufacturing

Engineers (SME) defined CIM as CIM is the integration of the total

manufacturing enterprise through the use of integrated systems and data

communications coupled with new managerial philosophies that improve

organizational and personal efficiency.

CIM basically involves the

integration of advanced technologies such as computer aided design (CAD),

computer aided manufacturing (CAM), computer numerical control (CNC), robots,

automated material handling systems, etc. Today CIM has moved a step ahead by

including and integrating the business improvement activities such as customer

satisfaction, total quality and continuous improvement. These activities are

now managed by computers. Business and marketing teams continuously feed the

customer feedback to the design and production teams by using the networking

systems. Based on the customer requirements, design and manufacturing teams can

immediately improve the existing product design or can develop an entirely new

product. Thus, the use of computers and automation technologies made the

manufacturing industry capable to provide rapid response to the changing

needs of customers.

2.4.

INDUSTRIAL ROBOTS

Industrial robots are

general-purpose, re-programmable machines which respond to the sensory signals

received from the system environment. Based on these signals, robots carry out

programmed work or activity. They also take simple independent decisions and

communicate/interact with the other machines and the central computer. Robots

are widely employed in the following applications in manufacturing:

a) Parts handling: it involves various

activities such as:

·

Recognizing,

sorting/separating the parts;

·

Picking and

placing parts at desired locations;

·

Palletizing and de-palletizing;

·

Loading and

unloading of the parts on required machines.

b) Parts processing: this may involves many

manufacturing operations such as:

·

Routing;

·

Drilling;

·

Riveting;

·

Arc welding;

·

Grinding;

·

Flame cutting;

·

Deburring;

·

Spray painting;

·

Coating;

·

Sand blasting;

·

Dip coating;

·

Gluing;

·

Polishing;

·

Heat treatment.

c) Product building: this involves development

and building of various products such as:

·

Electrical

motors;

·

Car bodies;

·

Solenoids;

·

Circuit boards

and operations like;

·

Bolting;

·

Riveting;

·

Spot welding;

·

Seam welding;

·

Inserting;

·

Nailing;

·

Fitting;

·

Adhesive bonding;

·

Inspection.

Further detail discussion on

various aspects of industrial robots such as its configuration, building

blocks, sensors, and languages has been carried out in the last module of this

course.

2.5.

AUTOMATIC QUALITY CONTROL AND INSPECTION SYSTEMS

Supply of a good quality

product or a system to the market is the basic aim of the manufacturing

industry. The product should satisfy the needs of the customers and it must be

reliable. To achieve this important product-parameter during a short lead time

is really a challenge to the manufacturing industry. This can be achieved by

building up the «quality» right from the product design stage; and maintaining

the standards during the «production

stages» till the

product-delivery to the market.

A number of sensors and

systems have been developed that can monitor quality continuously with or

without the assistance of the operator. These technologies include various

sensors and data acquisition systems, machine vision systems, metrology

instruments such as coordinate measuring machine (CMM), optical profilometers,

digital calipers and screw gauges etc. Now days the quality control activities

are being carried out right from the design stage of product development.

Various physics based simulation software is used to predict the performance of

the product or the system to be developed. In the manufacture of products such

as spacecrafts or airplanes, all the components are being critically monitored

by using the digital imaging systems throughout their development.

In the next module we will

study the various sensors, signal conditioning devices and data conversion

devices which are commonly used in mechatronics and manufacturing automation.