LECTURE ¹ 1

WHAT IS

«MECHATRONICS»

1.1.

What is «Mechatronics»

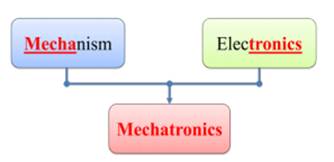

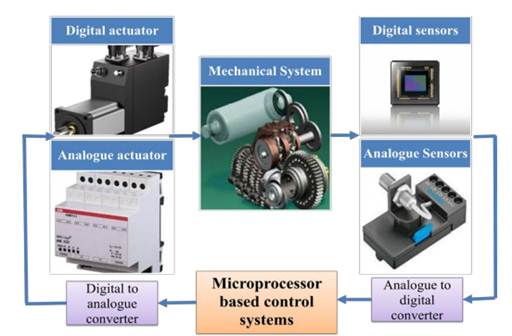

Mechatronics

is a concept of Japanese origin (1970’s) and can be defined as the application

of electronics and computer technology to control the motions of mechanical

systems (figure 1.1.).

Fig. 1.1. Definition of Mechatronics

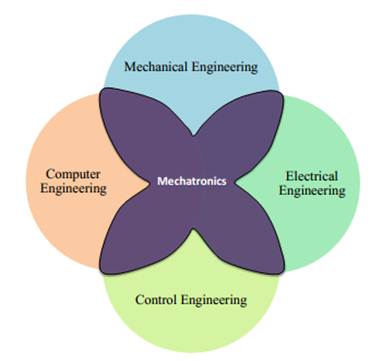

It is a multidisciplinary approach to product and manufacturing system

design (Figure 1.2). It involves application of electrical, mechanical, control

and computer engineering to develop products, processes and systems with

greater flexibility, ease in redesign and ability of reprogramming. It

concurrently includes all these disciplines.

Fig. 1.2. Mechatronics:

a multi-disciplinary approach

Mechatronics can also be

termed as replacement of mechanics with electronics or enhance mechanics with

electronics. For example, in modern automobiles, mechanical fuel injection systems are now replaced

with electronic fuel injection

systems.

This replacement made the automobiles more efficient and less pollutant.

With the help of microelectronics

and sensor technology, mechatronics systems are providing high levels of

precision and reliability. It is now possible to move (in x – y plane) the work

table of a modern production machine tool in a step of 0.0001 mm.

By employment of reprogrammable microcontrollers/microcomputers, it is

now easy to add new functions and capabilities to a product or a system.

Today’s domestic washing machines are «intelligent» and four-wheel passenger automobiles are equipped

with safety installations such as air-bags, parking (proximity) sensors,

anti-theft electronic keys etc.

1.2.

Importance of

Mechatronics in automation

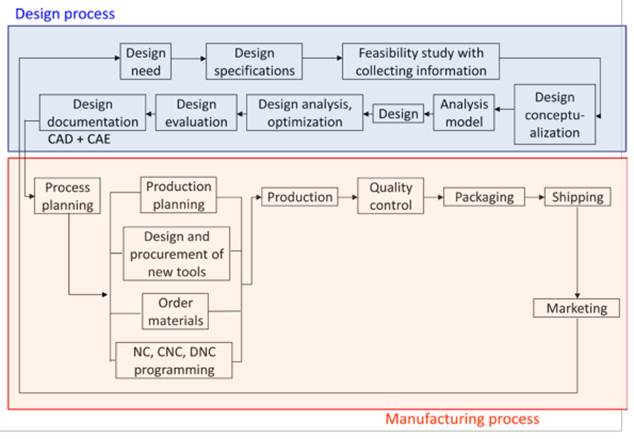

Fig.

1.2.1. Operations involved in

design and manufacturing of a product

Today’s customers are demanding more variety and

higher levels of flexibility in the products. Due to these demands and

competition in the market, manufacturers are thriving to launch new/modified

products to survive. It is reducing the product life as well as lead-time to

manufacture a product. It is therefore

essential to automate the manufacturing and assembly operations of a product.

There are various activities involved in the product manufacturing process.

These are shown in figure 1.2.3. These activities can be classified into two groups

viz. design and manufacturing activities.

Mechatronics concurrently employs the disciplines of

mechanical, electrical, control and computer engineering at the stage of design

itself. Mechanical discipline is employed in terms of various machines and

mechanisms, where as electrical engineering as various electric prime movers

viz. AC/DC, servo motors and other systems is used. Control engineering helps

in the development of various electronics-based control systems to enhance or

replace the mechanics of the mechanical systems. Computers are widely used to

write various softwares to control the control systems;

product design and

development activities; materials and

manufacturing resource planning, record keeping, market survey, and other sales

related activities.

Using computer aided design (CAD) / computer aided

analysis (CAE) tools, three-dimensional models of products can easily be

developed. These models can then beanalyzed and can be simulated to study their

performances using numerical tools. These numerical tools are being

continuously updated or enriched with the real-life performances of the similar

kind of products. These exercises provide an approximate idea about performance

of the product/system to the design team at the early stage of the product

development. Based on the simulation

studies, the designs can be modified to achieve better performances. During the

conventional design-manufacturing

process, the design assessment is

generally carried out after the production of first lot of the products. This

consumes a lot of time, which leads to longer (in months/years) product

development lead-time. Use of CAD–CAEtools saves significant time in comparison

with that required in the conventional sequential design process.

CAD-CAE generated final designs are then sent to the production and process planning

section. Mechatronics based systems such as computer aided manufacturing (CAM):

automatic process planning, automatic part programming, manufacturing resource

planning, etc. uses the design data provided by the design team. Based these

inputs, various activities will then be planned to achieve the manufacturing

targets in terms of quality and quantity with in a stipulated time frame.

Mechatronics

based automated systems such as automatic inspection and quality assurance,

automatic packaging, record making, and automatic dispatch help to expedite the

entire manufacturing operation. These systems certainly ensure a supply better

quality, well packed and reliable products in the market. Automation in the

machine tools has reduced the human intervention in the machining operation and

improved the process efficiency and product quality. Therefore it is important

to study the principles of mechatronics and to learn how to apply them in the

automation of a manufacturing system.

1.3.

MECHATRONICS SYSTEM

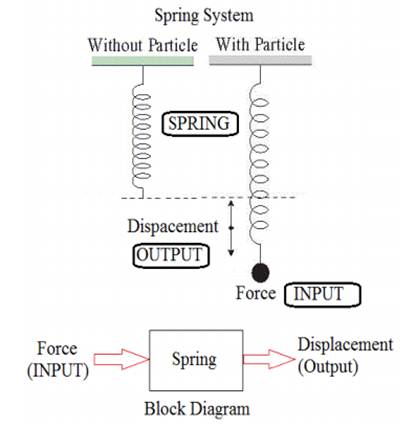

A system can be

thought of as a box or a bounded whole which has input and output elements, and

a set of relationships between these elements. Figure 1.3.1 shows a typical spring system. It has «force» as an input which produces an «extension». The input and output of this system follows the

Hooke’s law F = – kx, where F is

force in N, x is distance in m and k

is stiffness of the spring.

Fig.

1.3.1. A spring-force

system

Fig.

1.3.2. Constituents of a

mechatronics system

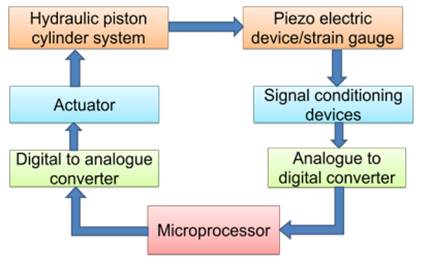

A Mechatronics

system integrates various technologies involving sensors, measurement systems,

drives, actuation systems, microprocessor systems and software engineering.

Figure 1.3.3 shows the basic elements of a mechatronics system. Consider the

example of a simple spring-mass system as shown in figure 1.3.2. To replace the

mechanics of this mechanical system with an equivalent mechatronics based

system, we need to have the basic controlling element, a microprocessor.

Microprocessor processes or utilizes the information gathered from the sensor

system and generates the signals of appropriate level and suitable kind

(current or voltage) which will be used to actuate the required actuator viz. A

hydraulic piston-cylinder device for extension of piston rod in this case. The

microprocessor is programmed on the basis of the principle of Hooks’ Law. The

schematic of microprocessor based equivalent spring mass system is shown in

figure 1.3.3.

Fig. 1.3.3. Microprocessor

based equivalent spring mass system

The input to the system is a force which can be sensed

by suitable electro-mechanical sensors viz. piezo-electric device or strain

gauges. These sensors generate either digital signals (0 or 1) or analogue

signals (milli-volts or milli-amperes). These signals are then converted into

right form and are attenuated to a right level which can properly be used by

the microprocessor to take generate the actuation signals. Various electronics

based auxiliary devices viz. Analogue-to-Digital Converter (ADC),

Digital-to-Analogue Converter (DAC), Op-amps, Modulators, Linearization

circuits, etc. are used to condition the signals which are either received by

the microprocessor from the sensors or are sent to the actuators from the

microprocessor. This mechatronics based spring-mass system has the input

signals in the digital form which are received from the ADC and Piezo-electric

sensor. The digital actuation signals generated by the microprocessors are

converted into appropriate analogues signals. These analogue signals operate

the hydraulic pump and control valves to achieve the desired displacement of

the piston-rod.

In this course we will be studying in detail the

various elements of a Mechtronics system (shown in figure 1.3.2) and their

applications to manufacturing automation.

In the next lecture we will

study the applications of Mechatronics in manufacturing engineering and in the

subsequent lectures; above-mentioned elements will be discussed in detail.