LECTURE ¹5

SENSORS AND SIGNAL PROCESSING.

SIGNAL CONDITIONING DEVICES

5.1. SIGNAL CONDITIONING

OPERATIONS

In previous lectures we have

studied various sensors and transducers used in a mechatronics system.

Transducers sense physical phenomenon such as rise in temperature and convert

the measurand into an electrical signal viz. voltage or current. However these

signals may not be in their appropriate forms to employ them to control a mechatronics

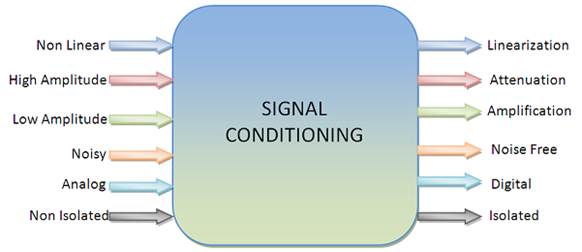

system. Figure 5.1.1 shows various

signal conditioning

operations which are being carried out in controlling

a mechatronics based system.

The signals given by a

transducer may be nonlinear in nature or may contain noise. Thus before sending

these signals to the mechatronics control unit it is essential to remove the

noise, nonlinearity associated with the raw output from a sensor or a transducer.

It is also needed to modify the amplitude (low/high) and form (analogue/digital)

of the output signals into respective acceptable limits and form which will be

suitable to the control system. These activities are carried out by using

signal conditioning devices and the process is termed as «signal conditioning».

Signal conditioning system

enhances the quality of signal coming from a sensor in terms of:

1. Protection (to protect the damage to the next element of

mechatronics system such microprocessors from the high current or voltage

signals);

2. Right type of signal (to

convert the output signal from a transducer into the desired form i.e. voltage

/ current);

3. Right level of the signal

(to amplify or attenuate the signals to a right /acceptable level for the next element);

4. Noise (to eliminate noise

from a signal);

5. Manipulation (to

manipulate the signal from its nonlinear form to the linear form).

Fig. 5.1.1. Signal

conditioning operations

Amplification/Attenuation

Various applications of

Mechatronics system such as machine tool control unit of a CNC machine tool

accept voltage amplitudes in range of 0 to 10 Volts. However many sensors

produce signals of the order of milli volts. This low level input signals from

sensors must be amplified to use them for further control action. Operational

amplifiers (op-amp) are widely used for amplification of input signals. The

details are as follows.

Operational

amplifier (op-amp)

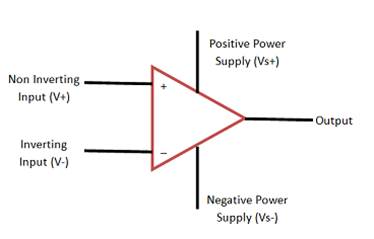

Operational Amplifier is a

basic and an important part of a signal conditioning system. It is often

abbreviated as op-amp. Op-amp is a high gain voltage amplifier with a

differential input. The gain is of the order of 100000 or more. Differential

input is a method of transmitting information with two different electronic

signals which are generally complementary to each other. Figure 2.6.2 shows the

block diagram of an op-amp. It has five terminals. Two voltages are applied at

two input terminals. The output terminal provides the amplified value of

difference between two input voltages. Op-amp works by using the external power

supplied at Vs + and Vs – terminals.

In general op-amp amplifies

the difference between input voltages (V+ and V-). The output of an operational

amplifier can be written as:

Vout = G * (V+ – V) (5.1)

where

G is Op-amp Gain.

Fig. 5.1.2. Circuit diagram of an Op-amp

5.2. BAND PASS

FILTER

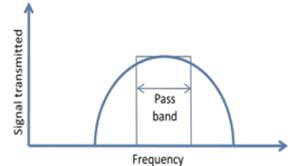

In some applications, we

need to filter a particular band of frequencies from a wider range of mixed

signals. For this purpose, the properties of low-pass and high-pass filters

circuits can be combined to design a filter which is called as band pass filter.Band

pass filter can be developed by connecting a low-pass and a high-pass filter in

series as shown in figure 5.2.1.

Fig. 5.2.1. Band pass filter

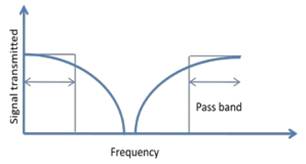

These filters pass all

frequencies above and below a particular range set by the

operator/manufacturer. They are also known as band stop filters or notch

filters. They are constructed by connecting a low-pass and a high-pass filter

in parallel as shown in Figure 5.2.2.

Fig. 5.2.2. Band reject

filter

5.3. PROTECTION,

CONVERSION AND PULSE WIDTH MODULATION

Protection

In many situations sensors

or transducers provide very high output signals such as high current or high

voltage which may damage the next element of the control system such as

microprocessor.

Protection from

high current

The high current to flow in

a sensitive control system can be limited by:

1. Using a series of

resistors;

2. Using fuse to break the

circuit if current value exceeds a preset or safe value.

Protection from

high voltage

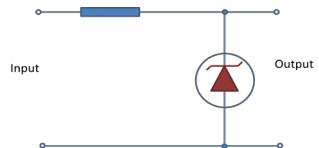

Zener diode circuits are

widely used to protect a mechatronics control system from high values of

voltages and wrong polarity. Figure 5.3.1 shows a typical Zener diode circuit.

Fig. 5.3.1. Zener diode

circuit diagram

Zener diode acts as ordinary

or regular diodes upto certain breakdown voltage level when they are

conducting. When the voltage rises to the breakdown voltage level, Zener diode

breaks down and stops the voltage to pass to the next circuit. Zener diode as

being a diode has low resistance for current to flow in one direction through

it and high resistance for the opposite direction. When connected in correct

polarity, a high resistance produces high voltage drop. If the polarity reverses,

the diode will have less resistance and therefore results in less voltage drop.

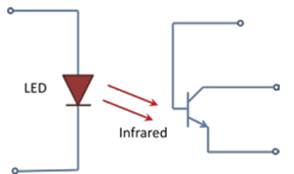

Fig. 5.3.2. Schematic of an

Optoisolator

In many high voltage

scenarios, it is required to isolate the control circuit completely from the

input high voltages to avoid the possible damage. This can be achieved by Optoisolators.

Figure 5.3.2 shows the typical circuit of an Optoisolator. It comprises of a

Light emitting diode (LED) and a photo transistor. LED irradiates infra red due

to the voltage supplied to it from a microprocessor circuit. The transistor

detects irradiation and produces a current in proportion to the voltage

applied. In case of high voltages, output current from Optoisolator is utilized

for disconnecting the power supply to the circuit and thus the circuit gets

protected.

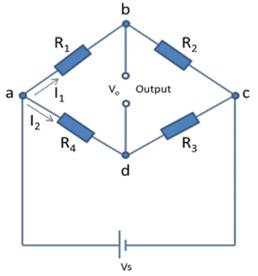

Wheatstone

bridge

Fig. 5.3.3. Configuration of

a Wheatstone bridge

Wheatstone bridge is used to

convert a resistance change detected by a transducer to a voltage change.

Figure 5.3.3 shows the basic configuration of a Wheatstone bridge.

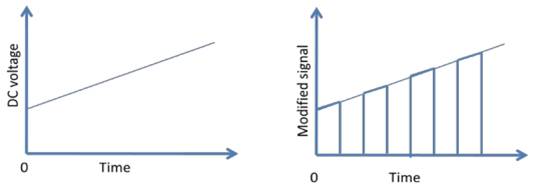

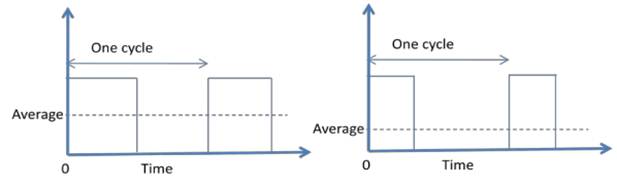

Pulse modulation

Fig. 5.3.4. Pulse amplitude

modulation

Fig. 5.3.5. Pulse width

modulation

During amplification of low

level DC signals from a sensor by using Op-amp, the output gets drifted due to

drift in the gain of Op-amp. This problem is solved by converting the analogue

DC signal into a sequence of pulses. This can be achieved by chopping the DC

signal in to a chain of pulses as shown in Figure 5.3.4. The heights of pulses

are related to the DC level of the input signal. This process is called as

Pulse Width Modulation (PWM). It is widely used in control systems as a mean of

controlling the average value of the DC voltage. If the width of pulses is

changed then the average value of the voltage can be changed as shown in Figure

5.3.5. A term Duty Cycle is used to define the fraction of each cycle for which

the voltage is high. Duty cycle of 50% means that for half of the each cycle,

the output is high.

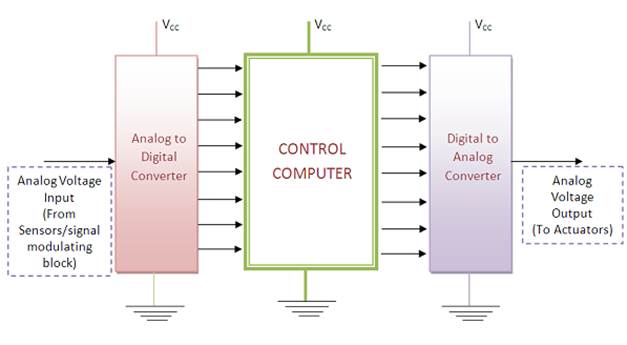

5.4. DATA

CONVERSION DEVICES

Data Conversion Devices are

very important components of a Machine Control Unit (MCU). MCUs are controlled

by various computers or microcontrollers which are accepting signals only in

Digital Form i.e. in the form of 0s

and 1s, while the signalsreceived

from signal conditioning module or sensors are generally in analogue form

(continuous). Therefore a system is essentially required to convert analog

signals into digital form and vis-à-vis. Analog to Digital Converter is

abbreviated as ADC. Figure 5.4.1 shows a typical control system with data

conversion devices.

Based on the signals received

from sensors, MCU generates actuating signals in the Digital form. Most of the

actuators e.g. DC servo motors only accept analogue signals. Therefore the

digital signals must be converted into Analog form so that the required

actuator can be operated accordingly. For this purpose Digital to Analog

Converters are used, which are abbreviated as DACs. In subsequent sections we

will be discussing about various types of ADC and DAC devices, their principle

of working and circuitry.

Fig. 5.4.1. A control system

with ADC and DAC devices

Comparators

In general ADCs and DACs

comprise of Comparators. Comparator is a combination of diodes and Operational

Amplifiers. A comparator is a device which compares the voltage input or

current input at its two terminals and gives output in form of digital signal

i.e. in form of 0s and 1s indicating which voltage is higher.

If V+ and V– be input voltages at two terminals of comparator then output of

comparator will be as:

V+ > V– ![]() Output 1;

Output 1;

V+ < V– ![]() Output 0.

Output 0.

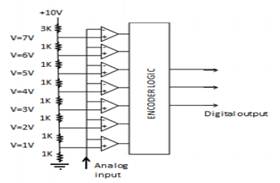

Encoders

Though the output obtained

from comparators are in the form of 0s

and 1s, but can’t be called as binary

output. A sequence of 0s and 1s will

be converted into binary form by using a circuit called Encoder. A simple

encoder converts 2n input

lines into «n» output lines. These «n» output lines follow binary algebra.

Analog to

Digital Converter (ADC)

As discussed in previous

section ADCs are used to convert analog signals into Digital Signals. There are

various techniques of converting Analog Signals into Digital signals which are

enlisted as follows. However we will be discussing only Direct Conversion ADC, detail study of other

techniques is out of the scope of the present course:

a.

direct

conversion ADC or flash ADC;

b.

successive

approximation ADC;

c.

a ramp-compare ADC;

d.

wilkinson ADC;

e.

integrating ADC;

f.

delta-encoded ADC

or counter-ramp;

g.

pipeline ADC (also

called subranging quantizer);

h.

sigma-delta ADC

(also known as a delta-sigma ADC);

i.

time –

interleaved ADC.

Direct

Conversion ADC or Flash ADC

Fig. 5.4.2. Circuit of Flash

ADC

Figure 5.4.2 shows the

circuit of Direct conversion or Flash ADC. To convert a digital signal of

N-bits, Flash ADC requires 2N - 1 comparators and 2N

resistors. The circuit provides the reference voltage to all the comparators.

Each comparator gives an output of 1 when its analog voltage is higher than

reference voltage or otherwise the output is 0. In the above circuit, reference

voltages to comparators are provided by means of resistor ladder logic.

The circuit described in

figure 5.4.2 acts as 3 Bit ADC device. Let us assume this ADC works between the

range of 0 – 10 Volts. The circuit requires 7 comparators and 8 resisters. Now

the voltages across each resistor are divided in such a way that a ladder of 1

volt is built with the help of 1K-Ohm resistances. Therefore the reference

voltages across all the comparators are 1 – 7 volts.

Now let us assume that an

input voltage signal of 2.5 V is to be converted into its related digital form.

As 2.5V is greater than 1V and 2V, first two comparators will give output as 1,

1. But 2.5V is less than 3, 4, 5, 6, 7 V values therefore all other comparators

will give 0s. Thus we will have

output from comparators as 0000011 (from top). This will be fed to the encoder

logic circuit. This circuit will first change the output in single high line

format and then converts it into 3 output lines format by using binary algebra.

Then this digital output from ADC may be used for manipulation or actuation by

the microcontrollers or computers.