LABORATORY WORK ¹14

INVESTIGATION OF POSITION

SENSOR CHARACTERISTICS

14.1.

Objective

Analyze

characteristics and applications of different position sensor types.

14.2.

Task

Use experimental

investigation to obtain sensibility characteristics of different

position sensor types:

·

inductive

proximity sensor;

·

capacitive

proximity sensor;

·

optical

proximity sensor;

·

ultrasonic

proximity sensor.

Investigate the optical proximity sensor usage for

rotation speed measurement.

14.3. Classification of

position sensors

A sensor is a

technical converter, which converts a physical variable (e.g. temperature,

distance, pressure) into a different, more easily evaluated variable (usually

an electrical signal). Additional terms for sensors are: encoders, effectors,

converters, detectors, transducers. Sensors are devices which can operate both

by means of contact, e.g. limit switches, force sensors, or without contact,

e.g. light barriers, air barriers, infrared detectors, ultrasonic reflective

sensors, magnetic sensors, etc. Even a simple limit switch can be interpreted

as a sensor.

According to the

output signal type sensors can be divided into 5 types.

Type A – sensors with switching signal output (binary signal

output). Examples – proximity sensors, pressure sensors, filling level sensor,

bimetal temperature sensor. These sensors can be connected directly to

programmable logical controllers (PLC).

Type B – sensors with pulse rate output. Examples –

incremental length and rotary angle sensors, quadrature encoders. Generally,

PLC-compatible interfaces are available.

Type C – sensors with analogue output and without integrated

amplifier and conversion electronics usually provide very small analogue output

signal (e.g. in the millivolt range), which is to be evaluated only by using

additional circuity. Examples – piezoresistive or piezoelectric sensor

components, Pt-100 or thermoelectric cells,

magnetoresistor and Hall

sensor components, pH and conductivity measuring

probes, potentiometers.

Type D – sensors with standardized analogue output and

integrated amplifier or conversion electronics. Typical output signals are: 0

to 10 V; 1 to 5 V; –5 to +5 V; 0 to 20 mA; 4 to 20 mA; –10 to +10 mA.

Type E – sensors and sensor systems with standardized digital

signal output interface, e.g. RS-232-C, RS-422-A, RS-485, CAN, Profibus, etc.

Sensors which

detect whether or not an object is located at a certain position are known as proximity sensors. Sensors of this type

provide a «Yes» or «No» statement depending on whether or not the position,

to be defined, has been taken up by the object. Usually these sensors have

binary output (Type A).With many production systems, mechanical position

switches are used to acknowledge movements which have been executed. Additional

terms used are micro-switches, limit switches or limit valves. Because

movements are detected by means of contact sensing, relevant constructive

requirements must be fulfilled. Also, these components are subject to wear. In

contrast, proximity sensors operate electronically and without contact.

The advantages

of contactless proximity sensors are:

·

Precise and

automatic sensing of geometric positions.

·

Contactless

sensing of objects and processes; no contact between sensor and workpiece is

required with electronic proximity sensors.

·

Fast switching

characteristics; as the output signals are generated electronically, the

sensors are bounce-free and do not create error pulses.

·

Wear-resistant

function; electronic sensors do not include moving parts which can wear out.

·

Unlimited number

of switching cycles.

·

Suitable

versions are also available for use in hazardous conditions (e.g. areas with

explosion hazard).

Today, proximity

sensors are used in many areas of industry for the reasons mentioned above.

They are used for sequence control in technical installations and for

monitoring and safeguarding processes. In this context sensors are used for

early, quick and safe detection of faults in the production process. The

prevention of damage to man and machine is another important factor to be

considered. A reduction in downtime of machinery can also be achieved by means

of sensors, because failure is quickly detected and signalled.

Inductive proximity sensors

Inductive

proximity sensors detect the presence of electrically conductive (metal)

objects that come within range of their oscillating field. Most of inductive

proximity sensors are operated using Eddy Current Killed Oscillator (ECKO)

principle. This type of sensor consists of few elements: coil, oscillator,

demodulator, trigger circuit, and an output (Fig. 14.3.1). The oscillator is an inductive capacitive tuned

circuit that creates a radio frequency. The electromagnetic field produced by

the oscillator is emitted from the coil away from the face of the sensor. The

circuit has just enough feedback from the field to keep the oscillator going.

When a metal target enters

the field, eddy currents circulate within the target. This causes a load on the

sensor, decreasing the amplitude of the electromagnetic field. As the target

approaches the sensor eddy currents increase, increasing the load on the

oscillator and further decreasing the amplitude of the field.

Demodulator removes the oscillator’s carrier and leaves only amplitude value. Schmitt

trigger circuit monitors the oscillator’s amplitude and at a predetermined

level switches the output state of the sensor from its normal condition. As the

target moves away from the sensor, the oscillator’s amplitude increases. At a

predetermined level the trigger switches the output state of the sensor back to

its normal condition.

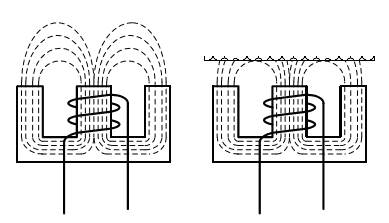

Fig. 14.3.1.

Magnetic fields in inductive proximity sensors

The ferrite core

concentrates the radiated field in the direction of use. A shielded proximity sensor has a metal ring placed around the

core to restrict the lateral radiation of the field. Shielded proximity sensors

can be flush mounted in metal. A metal-free space is recommended above and

around the sensor’s sensing surface. If there is a metal surface opposite to

the proximity sensor it must be at least three times the rated

sensing distance of the sensor from the sensing surface.

An unshielded

proximity sensor does not

have a metal ring around the core to restrict lateral radiation of the field.

Unshielded sensors cannot be flush mounted in metal. There must be an area

around the sensing surface that is metal free. An area of at least three times

the diameter of the sensing surface must be cleared around the sensing surface

of the sensor. In addition, the sensor must be mounted so that metal surface of

the mounting area is at least two times the sensing distance from the sensing

face. If there is a metal surface opposite to the proximity sensor it must be

at least three times the rated sensing distance of the sensor from the sensing

surface.

For sensing

distance normalization a standard target

is defined. A standard target is defined as having a flat, smooth surface, made

of mild steel that was 1 mm thick. Steel is available in various grades. Mild

steel is composed of a higher content of iron and carbon. The standard target

used with shielded sensors has sides equal to the diameter of the sensing face.

The standard target used with unshielded sensors has sides equal to the

diameter of the sensing face or three times the rated operating range,

whichever is greater. If the target is larger than the standard target, the

sensing range does not change. However, if the target is smaller or irregular

shaped the sensing distance (Sn)

decreases. The smaller the area of the target the closer it must be to the

sensing face to be detected.

Target Size Correction Factor. A correction factor can be applied when targets are

smaller than the standard target. To determine the sensing distance for a

target that is smaller than the standard target (Snew), multiply the rated sensing distance (Srated) by the correction

factor (T):

![]() (14.1)

(14.1)

Table 14.1

Target size correction

values

|

Size of Target compared to Standard Target |

Correction Factor |

|

|

Shielded |

Unshielded |

|

|

100% |

1.00 |

1.00 |

|

75% |

0.93 |

0.90 |

|

50% |

0.82 |

0.73 |

|

25% |

0.56 |

0.50 |

Thickness of the target is another factor that should be considered. The sensing

distance is constant for the standard target. However, for nonferrous targets

such as brass, aluminium, and copper a phenomenon known as «skin

effect» occurs. Sensing distance decreases as the target

thickness increases. If the target is other than the standard target a

correction factor must be applied for the thickness of the target.

The

target material also has an effect on the sensing distance. When the material

is other than mild steel correction factors need to be applied. The reduction

factors for FESTO SIEH M12 sensor (used in laboratory equipment) are presented

in Table 14.2.

Table 14.2

Target

material reduction factors for FESTO SIEH M12 inductive

proximity

sensor

|

Material |

Reduction Factor |

|

Steel S 265 JR (St 37) |

1.0 |

|

Stainless steel St 18/8 |

0.8 |

|

Brass |

0.5 |

|

Copper |

0.4 |

|

Aluminium |

0.4 |

Rated operating Distances. The rated sensing distance (Sn) is a theoretical value which does not take into

account such things as manufacturing tolerances, operating temperature, and

supply voltage. In some applications the sensor may recognize a target that is

outside of the rated sensing distance. In other applications the target may not

be recognized until it is closer than the rated sensing distance. Several other

terms must be considered when evaluating an application. The effective

operating distance (Sr) is

measured at nominal supply voltage at an ambient temperature of 23 °C ± 0.5 °.

It takes into account manufacturing tolerances. The effective operating

distance is ±10 % of the rated operating distance. This means the target will

be sensed between 0 and 90 % of the rated sensing distance. Depending on the

device, however, the effective sensing distance can be as far out as 110 % of

the rated sensing distance. The useful switching distance (Su) is the switching distance measured under specified

temperature and voltage conditions. The useful switching distance is ±10 % of

the effective operating distance.

The assured

(guaranteed) operating distance (Sa)

is any switching distance for which an operation of the proximity switch within

specific permissible operating conditions is guaranteed. The assured operating

distance is between 0 and 81 % of the rated operating distance.

The main

parameters for FESTO SIEH M12 inductive proximity sensor (used in laboratory

equipment) are presented in Table 14.3.

Table 14.3

The main parameters for the

FESTO SIEH M12 inductive

proximity sensor

|

Parameter |

Value |

|

Rated operating distance |

4 mm |

|

Assurred switching distance |

3.24 mm |

|

Repetition accuracy under constant conditions |

0.2 mm |

|

Hysterezis |

|

|

Max. switching frequency |

2500 Hz |

|

Max. output current |

200 mA |

14.4. Method of testing

1. Install the capacitive proximity sensor (looks like

blue plastic screw with wiring) on a testbench to the measuring scale as shown

in Fig. 6.10 and adjust the zero position.

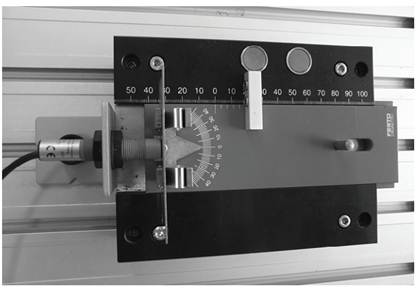

Fig. 14.4.1. Sensor and a

measurement scale installation

2.

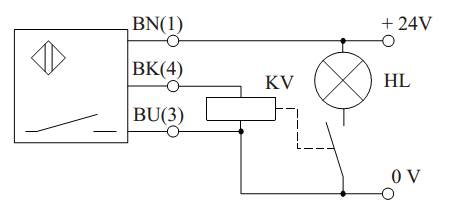

Connect the

sensor to a power supply and a load according to the scheme at Fig. 14.4.2,

using relay and indication units.

Fig. 14.4.2. Sensor

connection diagram

3.

Perform the

sensor switching distance measurements: for each of four provided material

plates (check the material!) find distances x1

– switch-off point moving from sensor; x2 – switch-on point moving to the sensor; ![]() – hysteresis.

Write the obtained results write in Table 14.4.

– hysteresis.

Write the obtained results write in Table 14.4.

Table 14.4.

Sensor testing results

|

Material |

|

|

|

|

Iron |

|

|

|

|

Aluminium |

|

|

|

|

Copper |

|

|

|

|

Plastic |

|

|

|

4.

Perform

step 1 to 3 for inductive and optical sensor.

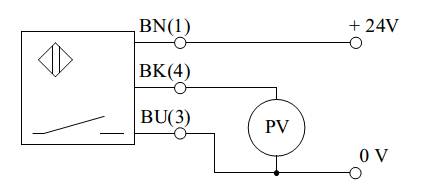

Fig.

14.4.3. Ultrasonic sensor connection diagram

5. Perform the ultrasonic sensor test: connect

it according to the schematic at Fig. 14.4.3, and measure the output voltage

moving the obstacle (perpendicular book) in front of the sensor every 5 cm till 1 m. Make a reliance graph.

6. Perform a motor shaft rotation speed

measurement using an optical retro-reflective proximity sensor. Take a look at

Fig. 14.4.4, and make connections: connect power to the counter, motor and

sensor; connect voltmeter to the motor unit control output; connect sensor

output to «CLOCK» input of counter unit. Put the counter unit switch to

the «imp. / s» position. Take a counter marks every 1V motor control

voltage increase and put them into Table 14.5. Calculate the rotation speed for each value using

formula:

![]() [rpm]

[rpm]

where: N – counter indication; n – pulse number per rotation (count the

holes on the disc). Make rotation speed ω

dependence to the control voltage chart.

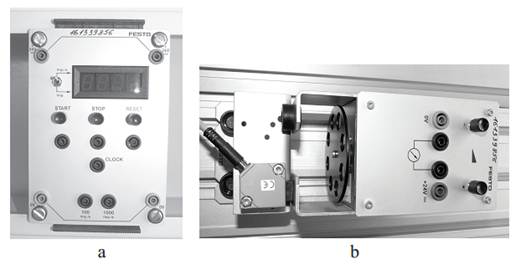

Fig. 14.4.4. Motor shaft

rotation speed measurement equipment: a – counter

unit; b – motor unit with

installed optical sensor

Table 14.5

Rotation speed measurement

results

|

Control voltage, V |

Counter indication, |

Rotation speed, rpm |

|

|

|

|

14.5.

Content of Report

1.

Objective, task

and model of the laboratory work.

2.

Work results

(connection diagrams, tables and charts).

3.

Conclusions.

14.6.

Control questions

1.

What does «proximity sensor» mean?

2.

Explain

operation principle of inductive proximity sensor.

3.

What are the

main characteristics of inductive proximity sensor?

4.

Explain

operation principle of capacitive proximity sensor.

5.

What are the

main characteristics of capacitive proximity sensor?

6.

Explain

operation principles of optical proximity sensor.

7.

What are the

main characteristics of optical proximity sensor?

8.

Explain

operation principles of ultrasonic proximity sensor.

9.

What are the

main characteristics of ultrasonic proximity sensor?

10. Find three application examples for each mentioned

sensor type.