LABORATORY WORK ¹ 13

INVESTIGATION OF STEPPER

MOTOR. RESONANCE

13.1. Objectives

Analyze characteristics of stepper motor using different connection and

control modes.

13.2. Task

Use experimental investigation to obtain maximum rotation speed and

other characteristics of different stepper motor connection modes – unipolar

and bipolar. Test and examine successive control modes:

·

full step;

·

wave;

·

half step;

·

break.

13.3. Resonance

At specific step

rates stepper motors often experience an undesired reaction called resonance.

The indications are a sudden loss of torque with possible skipped steps and

loss of synchronization. Resonance is inherent in the design and operation of

all step-ping motors. Slow stepping rates combined with high rotor inertia and

elevated torque produce ringing as the rotor overshoots its de-sired angular

displacement and is pulled back into position. Resonance arises when the step

rate coincides with rotor ringing, typically about 100 to 200 steps/sec. Unable

to overcome the combined effects of both load inertia and ringing, the motor

skips steps and loses torque and synchronization. The resonant frequency of the

stepper motor rotor depends on the amplitude of the oscillation, but as the

amplitude decreases, the resonant frequency rises to a well-defined

small-amplitude frequency. This frequency depends on the step angle and on the

ratio of the holding torque to the moment of inertia of the rotor. Either a

higher torque or a lower moment will increase the frequency. Formally, the

small-amplitude resonance can be computed as follows: First, recall Newton’s

law for angular acceleration:

![]() (13.1)

(13.1)

where: T –

torque applied to rotor; µ – moment

of inertia of rotor and load, A –

angular acceleration [rad/s]. For small amplitudes, the torque on the rotor can

be approximated as a linear function of the displacement from the equilibriun

position. Therefore, Hooke’s law is applied:

![]() (13.2)

(13.2)

where: k –

the «spring constant» of the system, in torque units per radian; ![]() – angular position of rotor [rad].

– angular position of rotor [rad].

From (13.1) and (13.2) is solution of the resonant frequency f as

function of k and µ is:

(13.3)

(13.3)

It is very

important, that moment of inertia of the rotor plus any coupled load matters,

so the resonant frequency depends on the load. In practice, this oscillation

can cause significant problems when stepping rate is anywhere near a resonant

frequency of the system – random and uncontrollable motion can appear.

Changing any one

of the three parameters – inertia load, step rate, or torque – will reduce or

eliminate resonance. As a practical matter, only torque is the easiest to

change using a technique called micro-stepping. Micro-stepping applies power to the stator windings of the

mo-tor in incremental steps. Torque builds slowly reducing overshoot and

canceling resonance.

Time Constant

Because of motor

winding inductance, the current will not increase or decrease instantaneously.

If a voltage V is connected to a

winding with the resistance Rand inductance L,

the current in-creases exponentially:

![]()

![]() (13.4)

(13.4)

Value L / R

is called time constant and indicates time needed for the current to rise up to

63 % of the final value i = V / R.

For the equipment motor with R = 2.5

and L = 8 mH used in laboratory the time constant τ = L / R = 3.2 ms. It means, the step switching

frequency is limited to about 200 steps per second. There is a way to increase

maximal rotation speed: time constant τ

can be decreased sing additional series connected resistor (increasing R) and accord ingly increased supply

voltage to reach the normal motor current. If the 10 resistor added and supply

voltage increased to 25 V, τ = 0.64

ms, and 1000 steps per second speed

can be reached.

The Workflow

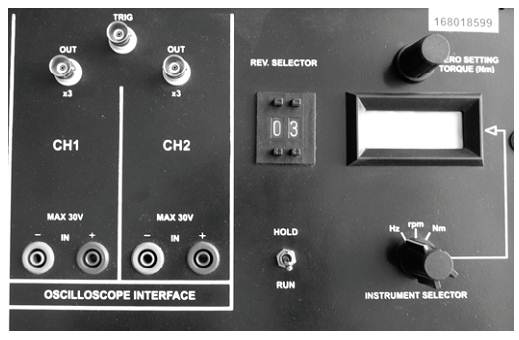

The laboratory

equipment for the stepper motor investigation – TERCO SD1664-1 Stepper motor

trainer is shown in Fig. 13.1. It consists of a motor block with adjustable

load on the left, and control block in the centre. Closer view of control

measurement part is presented in Fig. 13.2. The oscilloscope for voltage form

monitoring and voltmeter for coil current measurement are necessary.

Fig. 13.1. Stepper motor TERCO SD1664-1

Measurement equipment

connection

Fig. 13.2. Measurement part of stepper motor train

13.4. Method of testing

Maximum

pull-in, pull-out and torque characteristic measurement.

1.

Set «Speed» potentiometer to the minimum value. Turn down the adjusting screw until

the braking cord is loose. Switch «Instrument selector» to torque mode (Nm), adjust zero on display by «Zero setting torque» potentiometer (Fig. 13.1).

2.

Switch «Instrument selector» to frequency mode (Hz), select «Unipolar» in driver section and «Normal» in «Program selector».

3. Start the motor at very low speed, stop and restart

the motor (use the Hold/Run switch). Increase the frequency until the motor

does not start properly and write the frequency value into table 13.1.

4.

Adjust three

different torque values in range 0 – 1 Nm, and re-peat procedure 3.

5.

Repeat steps 3

and 4 for bipolar mode.

6.

Repeat steps 3 – 5 using one and

two additional weights on motor shaft, fill in the results into table 13.1.

7.

Measure the

maximum pull-in torque: loose the braking cord; select «Unipolar» in driver section and «Normal» in «Program selector»; set the operational frequency 20 Hz; increase the

torque and try to restart the motor. Proceed until the motor cannot start, and

write down the obtained torque value in table 13.2.

8.

Repeat step 7

for 50 Hz, 100 Hz, 200 Hz, 400 Hz, 600 Hz and 800 Hz operational frequency and

write down the data in table 13.2.

9.

Repeat steps 7

and 8 using bipolar conection mode.

10. Measure the maximum pull-out torque: loose the braking

cord; select «Unipolar» in driver section and «Normal» in «Program selector»; set the operational frequency 20 Hz; run the motor and

increase the torque. Proceed until the motor stops, and write down the obtained

torque value in table 13.2.

11. Repeat step 10 for 50 Hz, 100 Hz, 200 Hz, 400 Hz, 600

Hz and 800 Hz operational frequency and write down the data in table 13.2.

12. Repeat steps 10 and 11 using bipolar conection mode.

Table 13.1.

The maximum pull-out rate

|

Weight No |

Load, Nm |

Frequency, Nz |

|

|

|

|

Unipolar |

Bipolar |

|

|

|

|

|

Table 13.2.

The maximum pull-in and

pull-out torq

|

Mode |

Maximum torque, Nm |

||||||

|

20 Hz |

50 Hz |

100 Hz |

200 Hz |

400 Hz |

600 Hz |

800 Hz |

|

|

Pull-in unipolar |

|

|

|

|

|

|

|

|

Pull-in bipolar |

|

|

|

|

|

|

|

|

Pull-out unipolar |

|

|

|

|

|

|

|

|

Pull-out bipolar |

|

|

|

|

|

|

|

13.5.

Content of Report

1.

Objective, task and motor parameters of the laboratory work.

2.

Work results for Experiment 1 – table with maximum rotation speed achieved

using different connection and control modes; control pulse and coil voltage

oscillograms, coil current de-pendence from pulse frequency for the offered

control mode, ramping diagram.

3.

Work results for

Experiment 2: maximum pull-out, resonance and maximum pull-in frequency values

for both unipolar and bipolar connection modes of unloaded motor and with

addition-al load.

4.

Work results for

Experiment 3: maximum pull-in and pull-out rates (Table 13.1) and torques

(Table 13.2) for different operation modes.

5.

Conclusions.

13.6. Control questions

1.

Enumerate

advantages and drawbacks of stepper motors.

2.

What are the

main connection types for stepper motors?

3.

How do the

parameters depend on connection type?

4.

What are control

modes for stepper motors?

5.

What control

mode can achieve maximum rotation speed?

6.

What is the

speed resonance and how to avoid it?

7.

What is the

back-phasing mode?

8.

Explain the ramp

mode using the diagram.

9.

How to find the

maximum pull-in and pull-out frequency?

10. How to find the maximum pull-in and pull-out torque?