LABORATORY WORK ¹ 12

CONNECTION TYPES

12.1.

Objectives

Analyze

characteristics of stepper motor using different connection and control modes.

12.2.

Task

Use experimental

investigation to obtain maximum rotation speed and other characteristics of

different stepper motor connection modes – unipolar and bipolar. Test and

examine successive control modes:

ü

full step

ü

wave

ü

half step

ü

break

12.3.

Connection types

The most popular

hybrid stepper motors usually have two pairs of windings (sometimes for very

precise systems 5 winding motors are used). If these windings have separate

outputs (8 wires), the pole coils can be freely connected in series or

parallel. A series connection provides a high inductance and therefore greater

performance at low speeds. A parallel connection will lower the inductance but

increase the torque at faster speeds.

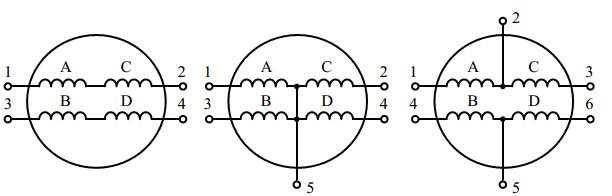

Otherwise the

windings can be connected in series inside the motor, and 4, 5 or 6 wires

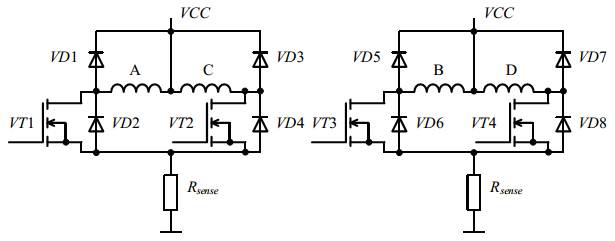

motors (Fig. 12.1) are available. Depending to the wiring, unipolar (Fig. 12.2)

or bipolar (Fig. 12.3) stepper motor connection is possible.

Fig. 12.1. 4, 5 or 6 wire

stepper motor winding connections

Fig. 12.2. Unipolar

stepper motor connection

The direction of

current flow in unipolar connection (Fig. 12.2) is opposite in sections A and C

of the coil. But one coil from the same pole is on (open VT1 or VT2 for A-C,

and VT3 or VT4 for B-D), and current flow in a particular section of the coil

is always unidirectional. Only 5, 6 or 8 wires motors can be connected

unidirectionally.

Bipolar stepper

motors do not need the centre tap. That makes the motor construction easier,

but it needs a different type of driver circuit, which reverses the current

flow through the entire coil by alternating the polarity of the terminals,

giving us the name «bipolar», and windings can not have the common centre tap

like 5 wire winding connection.

A bipolar motor

is capable of higher torque since the entire coil is energized, not just half.

Let’s look at the mechanism for reversing the voltage across one of the coils,

as shown in Fig. 12.3. This circuit is called an H-bridge, because it resembles

a letter «H». The current can be reversed through the coil by opening the

appropriate transistors. If transistors VT1 and VT4 are open, then the current

flows in one direction, and if transistors VT2 and VT3 are open, then the

current flows in the opposite direction.

Fig. 12.3. Bipolar

stepper motor connection

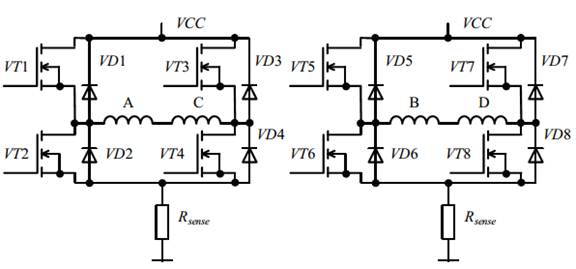

Control Modes

Full step (normal, «two phase on») mode

(Fig. 12.4). In this method, both windings of the motor are

always energized. Instead of making one winding off and another on, in

sequence, only the polarity of one winding at a time is changed. With the

current flowing in both windings simultaneously, the rotor aligns itself

between the «average

north» and «average south» magnetic poles. Since both phases are always «ON», this method gives 41.4 % more torque than «One Phase ON» stepping.

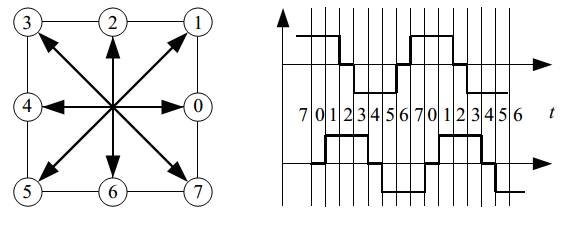

Fig. 12.4.

Full step control mode

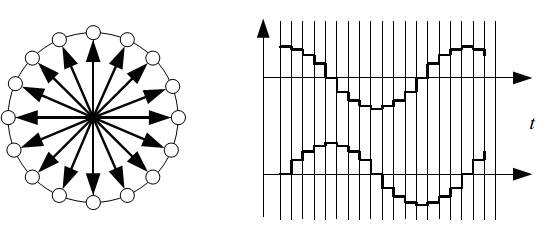

Half step mode

(Fig. 12.5). Half step is a combination of full step and wave

modes, the number of steps per rotation is doubled, step size is decreased in

half. Resonant effects can be reduced, but for the same rotation speed the

doubled pulse frequency is needed.

Fig. 12.5. Half step

control mode

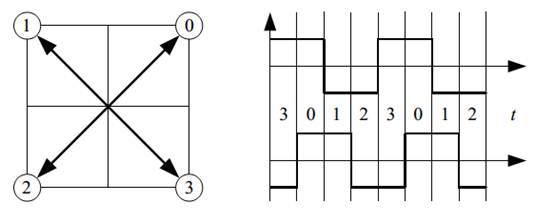

Break mode (Back phasing).When operating the motor at

frequencies that are considerably below the time constant, extra pulses can be

supplied in order to improve the rotor positioning. At low stepping rates,

typically below 250 steps/s, the instability due to inherent resonance can be

eliminated by a form of electrical damping called «back phasing». The damping is accomplished by adding a half step

backward to every step forward. After a full step forward, just before the new

position has reached, a half step pulse is given in the opposite direction

causing the rotor to reverse. Before moving backwards another half pulse is not

given in the forward direction. This is the same as to go back to the former

new stable position to lock the rotor there. The break pulse position and

duration is adjust-able. There are drawbacks of this mode: the net torque

decreases, and it is difficult to control the pulse form at higher frequencies.

Usually 250 steps/s is the upper limit for the back phasing usage.

Microstep mode is the

further improvement of half step mode. The coil current can be not only

switched on and off, but can be gradually regulated. Depending to the pole coil

current ratio the intermediate rotor positions can be obtained. The coil

current is equal.

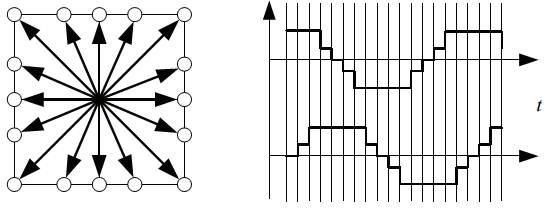

Fig.

12.6. Microstepping with sinusoidal current regulation

To simplify the

regulation and to increase torque is possible using square microstepping

control (Fig. 12.7)

– only one current is regulated per half step, other remains maximum.

Fig. 12.7. Microstepping

with square (one coil per half step) current regulation

12.4.

Method of testing

Find the Maximum

pull-out, Resonance and Maximum pull-in frequency.

1.

Connect

oscilloscope to windings – CH1 to A1 and A2, CH2 – to B1 and B2, set «Speed» potentiometer to the minimum value.

2.

Switch «Instrument selector» to torque mode (Nm), adjust zero on display by «Zero setting torque» potentiometer (Fig. 12.7).

3.

Switch «Instrument selector» to frequency mode (Hz), select «Unipolar» in driver section and «Normal» in «Program selector». Start the motor.

4. Increase the frequency slowly until the motor starts

to sound differently. The resonance frequency may cause the motor to miss steps

or stall. Monitor and save the curves on oscilloscope, write down the resonant frequency.

5.

Continue

increasing the frequency until the motor finaly stops. Write down the Maximum

pull-out frequency.

6.

Find out the Maximum pull-in

rate. Stop the motor, adjust the frequency and find the value when the motor

cannot be started. Write down this value.

7.

Repeat steps 3 – 6 in Bipolar

mode.

8.

Mount the

additional weight on the motor shaft, and repeat steps 3 – 6. Note the

possibility to find the resonance.

12.5.

Content of Report

1.

Objective, task

and motor parameters of the laboratory work.

2.

Work results for

Experiment 1 – table with maximum rotation speed achieved using different

connection and control modes; control pulse and coil voltage oscillograms, coil

current dependence from pulse frequency for the offered control mode, ramping

diagram.

3.

Work results for

Experiment 2: maximum pull-out, resonance and maximum pull-in frequency values

for both unipolar and bipolar connection modes of unloaded motor and with addition-al

load.

4.

Work results for

Experiment 3: maximum pull-in and pull-out rates (Table 12.1) and torques (Table 12.2) for different operation modes.

5.

Conclusions.

12.6. Control

questions

1.

Enumerate

advantages and drawbacks of stepper motors.

2.

What are the

main connection types for stepper motors?

3.

How do the

parameters depend on connection type?

4.

What are control

modes for stepper motors?

5.

What control

mode can achieve maximum rotation speed?

6.

What is the

speed resonance and how to avoid it?

7.

What is the

back-phasing mode?

8.

Explain the ramp

mode using the diagram.

9.

How to find the

maximum pull-in and pull-out frequency?

10. How to find the maximum pull-in and pull-out torque?