LABORATORY WORK ¹ 11

INVESTIGATION OF STEPPER

MOTOR

11.1. Objectives

Analyze

characteristics of stepper motor using different connection and control modes.

11.2.

Tasks

Use experimental

investigation to obtain maximum rotation speed and other characteristics of

different stepper motor connection modes – unipolar and bipolar. Test and

examine successive control modes:

·

full step;

·

wave;

·

half step;

·

break.

11.3. Constructions and

operational principles of stepper motor

The terms

stepper motor, stepping motor, and step motor are synonymous and are often used

interchangeably. A stepper motor is a device that converts a DC voltage pulse

train into a proportional mechanical rotation of its shaft. In essence, stepper

motors are discrete versions of the synchronous motor. The discrete motion of

the stepper motor makes it ideally suited for use with a digitally based

control system such as a microcontroller. Stepper motors have very good low

speed and holding torque, can run «open-loop» without the need for any kind of encoder to determine

the shaft position. The rotation speed of a stepper is independent of load,

provided it has sufficient torque to overcome slipping. The higher rpm a

stepper motor is driven, the more torque it needs, so all steppers eventually

poop out at some rpm and start slipping. Slipping is usually a disaster for

steppers, because the position of the shaft becomes unknown. There are three

basic types of stepper motors:

1.

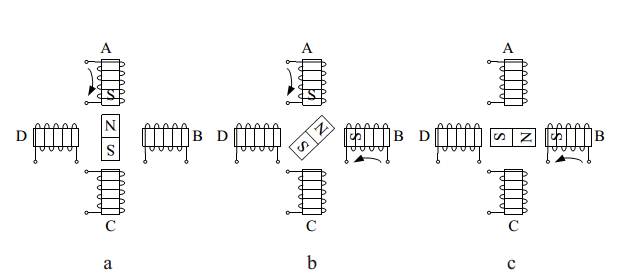

Permanent-magnet(PM) stepper motors, which have magnetized rotors. Operational principle

is shown in Fig. 11.1 – changing

the winding currents it is possible to change the magnetic field and magnetized

rotor position.

2.

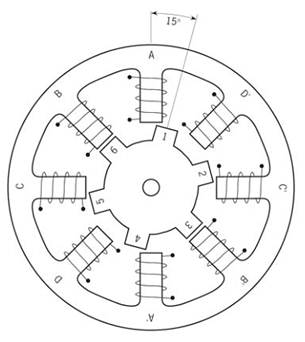

Variable-Reluctance (VR) stepper motors, which have soft-iron rotors with a wound stator

(Fig. 11.2). The number of teeth on the rotor and stator, together with the

winding configuration and excitation determines the step angle. This type of

stepper motor provides small to medium sized step angles and is capable of

operation at high stepping rates. A disadvantage of VR step-per motors is that

since the rotor is not magnetized, the holding torque is zero when the stator

windings are not energized (power off). Hence, there is no capability to hold a

mechanical load at a given position under power-off conditions unless

mechanical brakes are employed.

Fig. 11.1. Operational principle of a permanent-magnet stepper motor

3.

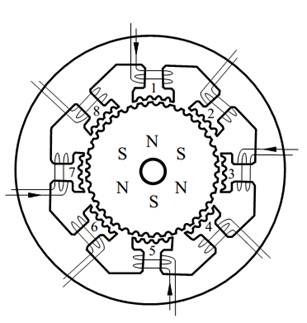

Hybridstepper motors, which have two stacks of rotor teeth forming the two poles of a

permanent magnet located along the rotor axis. The hybrid stepper motor is a

combination of the previous two types. Typically the stator has eight salient

poles, which are energized by a two-phase winding (Fig. 11.3). The rotor

consists of a cylindrical magnet, which is axially magnetized. The step angle

depends on the method of construction and is generally in the range 0.9°– 5°.

The most popular step angle is 1.8° – 200 steps per rotation. In this case

rotor has 50 teeth, and there are 4 winding poles.

Fig. 11.2. Operational principle of a variable-reluctance stepper

mo

Fig. 11.3. Operational

principle of hybrid stepper motor

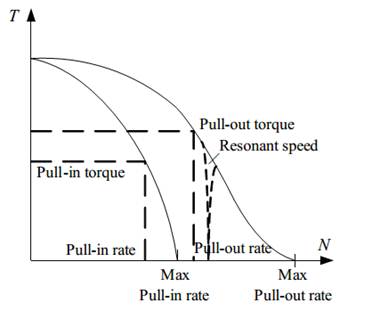

The stepper

motor characteristics (Fig. 11.4) can be described using the main terms:

·

Pull-out torque: The maximum torque that can be applied to a motor, running at a given

stepping rate, without losing synchronism.

·

Pull-in torque: The maximum torque against which a motor will start, at a given pulse

rate, and reach synchronism without losing a step.

·

Dynamic torque: The torque developed by the motor at very slow stepping speeds.

Fig. 11.4. General

characteristics of a typical stepper motor

·

Holding torque: The maximum torque that can be applied to an energized stationary motor

without causing spindle rotation.

·

Pull-out rate (maximum rotation speed): The maximum switching rate at which a motor

will remain in synchronism while the switching rate is gradually increased.

·

Pull-in rate: The maximum switching rate at which a loaded motor can start without

losing steps.

·

Slew range: The range of switching rates between pull-in and pull-out in which a

motor will run in synchronism but cannot start or reverse.

11.4. Method of

testing

Single mode.

1.

In «PRPGRAM

SELECTOR» (Fig. 11.3) school the «SINGLE» mode. Try to rotate the motor shaft

by hand in «STOP/PROGRAM» and «START/RUN» modes, note the difference. Measure

and note the current values in both modes.

2.

Press the button

«SINGLE STEP». Count the steps for a one complete motor shaft turn, compare

obtained number with given data. Try to change step direction (Fig. 11. 2).

Normal mode.

1.

In «PROGRAM

SELECTOR» (Fig. 11.3) choose the «NORMAL» mode. Select «BIPOLAR» mode in Driver

section. Connect Oscilloscope interface CH1 inputs to a1 and a2, CH2 inputs –

to b1 and b2. Set the SPEED potentiometer to a minimum position.

2.

Switch on to the

«START/RUN» mode. Sowly increase the rotation speed watching the scope curves

and current values until

3.

motor goes out

of sinchronization. Note the maximum rotation speed and pulse frequency.

Measure the coil current at different switching frequencies (from 0 till

maximum every 10 Hz) and make a dependence chart.

4.

Connect

oscilloscope to the windings – CH1 to the A1 and A2, CH2 – to the B1 and B2 and

check curves at different rotation speed. Make a screen shots at high speed, at

lower speed when current protection occurs, and at very low speed, when voltage

oscillations are visible.

Wave mode.

1.

In «PROGRAM SELECTOR» (Fig. 11.3) choose the «WAVE» mode. Repeat all steps like in Normal mode.

Half step mode.

1.

In «PROGRAM SELECTOR» (Fig. 11.3) choose the «HALF STEP» mode. Repeat all steps like in Normal mode.

2.

Note the pulse

frequency and rotation speed differencies com-paring to the full step modes.

Break mode.

1.

In «PROGRAM SELECTOR» (Fig. 11.3) choose the «BREAK» mode. Repeat all steps like in Normal mode.

2.

Try to adjust «Brake Time» and «Delay», note the

differencies in waveforms and motor work at various settings.

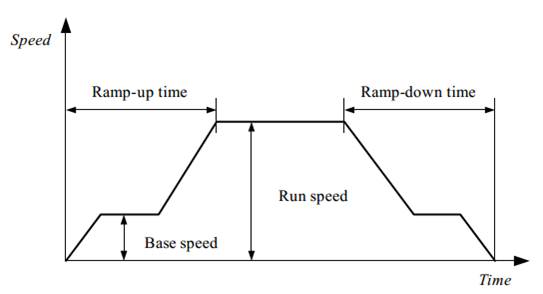

Ramp mode.

1.

In «PROGRAM SELECTOR» (Fig. 11.3) choose the «RAMP» mode. A typical ramping profile is presented.

2.

Turn «Base speed» to 20 % and «Run speed» to 50 %.

3.

Set «Ramp up» and «Ramp down» to 100 %.

4.

In «Rev selector» choose a certain number of turns.

5.

Run the motor

and note the process.

6.

Repeat the test

by decreasing the ramping time first «Ramp up» and later «Ramp down», note the results.

7.

Change «Base speed» and «Run speed» values. Try «Base speed» greater than «Run speed», see what happens.

8.

Draw and test

your own ramping diagram (Fig. 11.5).

Fig. 11.5. A typical two

phase ramping profile

11.5. Content of Report

1.

Objective, task

and motor parameters of the laboratory work.

2.

Work results for

Experiment 1 – table with maximum rotation speed achieved using different

connection and control modes; control pulse and coil voltage oscillograms, coil

current dependence from pulse frequency for the offered control mode, ramping

diagram.

3.

Work results for

Experiment 1: maximum pull-out, resonance and maximum pull-in frequency values

for both unipolar and bipolar connection modes of unloaded motor and with

addition-al load.

4.

Work results for

Experiment 2: maximum pull-in and pull-out rates (Table 11.1) and torques

(Table 11.2) for different operation modes.

5.

Conclusions.

11.6. Control questions

1.

Enumerate

advantages and drawbacks of stepper motors.

2.

What are the

main connection types for stepper motors?

3.

How do the

parameters depend on connection type?

4.

What are control

modes for stepper motors?

5.

What control

mode can achieve maximum rotation speed?

6.

What is the

speed resonance and how to avoid it?

7.

What is the back-phasing

mode?

8.

Explain the ramp

mode using the diagram.

9.

How to find the

maximum pull-in and pull-out frequency?

10. How to find the maximum pull-in and pull-out torque?