LABORATORY WORK ¹10

DEVELOPMENT OF EQUIVALENT

CIRCUITS

1.1.

Objectives

Get acquainted with starting transients of the current and velocity of

the squirrel-cage induction motor.

1.2.

Tasks

1.

Experimentally

obtain starting transients of motor phase cur-rent at no load.

2.

Experimentally

obtain starting transients of motor speed at no load.

1.3.

Development of equivalent circuits

The three-phase

induction motor is represented by a stationary equivalent circuit.

Considering the

rotor first and recognizing that the frequency of rotor currents is the slip

frequency, we may express the per-phase rotor leakage reactance ![]() at a slip s in terms of the standstill per

phase reactance

at a slip s in terms of the standstill per

phase reactance ![]() :

:

![]() (10.1)

(10.1)

Next we observe that

the magnitude of the voltage induced in the rotor circuit is also proportional

to the slip.

A justification

of this statement follows from transformer theory because we may view the

induction motor at standstill as a transformer with an air gap. For the

transformer, we know that the induced voltage, say ![]() , is given by:

, is given by:

![]() (10.2)

(10.2)

But at a slip s,

the frequency becomes sf. Substituting this value of frequency for Eq. (10.2)

yields the voltage ![]() at a slip s

as:

at a slip s

as:

![]() =

=![]() (10.3)

(10.3)

If ![]() is the

per-phase voltage induced in the rotor at standstill, then the voltage

is the

per-phase voltage induced in the rotor at standstill, then the voltage ![]() at a slip s is given by:

at a slip s is given by:

![]() (10.4)

(10.4)

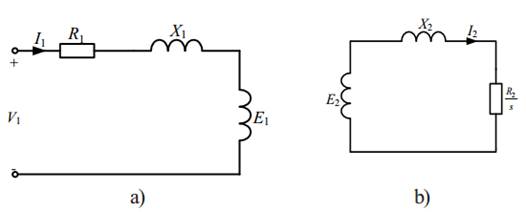

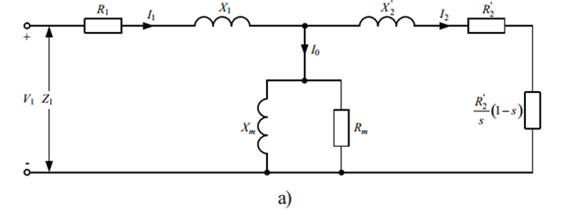

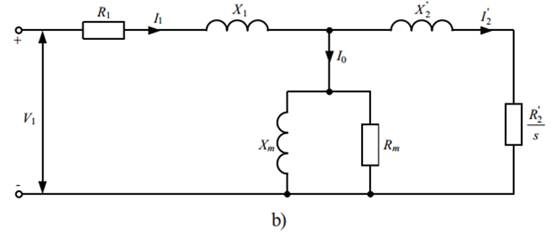

Using Eqs.

(10.3) and (10.4), we obtain the rotor equivalent circuit shown in Fig. 10.1 a.

The rotor current ![]() is given by:

is given by:

(10.5)

(10.5)

which may be

rewritten as:

(10.6)

(10.6)

resulting in the alternative form of the equivalent

circuit shown in Fig. 10.1 b. Notice that these circuits are drawn on a

per-phase basis. To this circuit we may now add the per-phase stator equivalent

circuit to obtain the complete equivalent circuit of the induction mo-tor.

In an induction

motor, only the stator is connected to the ac source. The rotor is not

generally connected to an external source, and rotor voltage and current are

produced by induction. In this regard, as mentioned earlier, the induction

motor may be viewed as a transformer with an air gap, having a variable

resistance in the secondary. Thus, we may consider that the primary of the

trans-former corresponds to the stator of the induction motor, whereas the

secondary corresponds to the rotor on a per-phase basis. Because of the air

gap, however, the value of the magnetizing reactance Xm tends to be relatively low, compared to that of a

transformer. As in a transformer, we have a mutual flux linking both the stator

and the rotor, represented by the magnetizing reactance and various leakage

fluxes. For instance, the total rotor leakage flux is denoted by X2 in Fig. 10.1.

Fig. 10.1. Stator and

rotor as coupled circuits

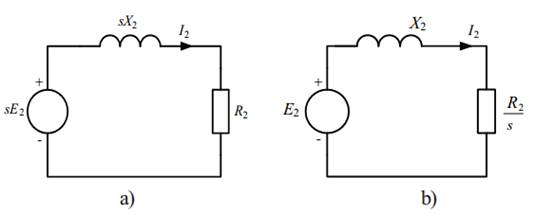

Now considering

that the rotor is coupled to the stator as the secondary of a transformer is

coupled to its primary, we draw the circuit shown in Fig. 10.2.

Fig. 10.2. Two forms of

rotor equivalent circuit

To develop this

circuit further, we need to express the rotor quantities as referred to the

stator. However, having referred the rotor quantities to stator, we obtain from

the circuit given in Fig. 10.2 the exact equivalent circuit (per phase) shown

in Fig. 10.3.

Fig. 10.3. Two forms of

equivalent per phase circuit of induction motor

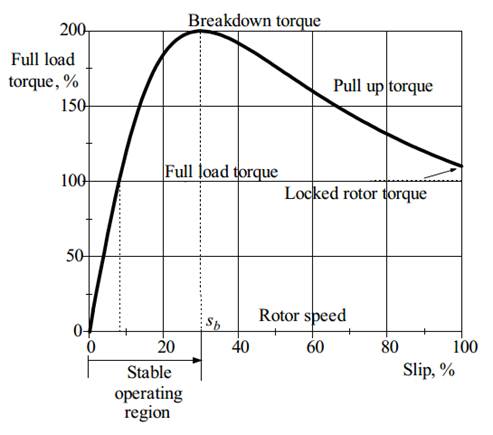

Performance criteria of

induction motors

The performance

of an induction motor may be characterized by the following major factors:

locked rotor torque and current, pull up torque, breakdown torque and percent

slip. In addition, full-load torque and current must be considered when

evaluating an application.

Locked Rotor Torque. Locked rotor torque, also referred to as starting

torque, is developed when the rotor is held at rest with the rated voltage and

frequency applied. This condition occurs each time the motor is started. When

the rated voltage and frequency are applied to the stator there is a brief

amount of time before the rotor turns.

Locked Rotor Current. Locked rotor current is also referred to as starting

current. This is the current taken from the supply line at the rated voltage

and frequency with the rotor at rest.

Pull Up Torque. Pull up torque is the torque developed during

acceleration from start to the point breakdown torque occurs.

Breakdown Torque. Breakdown torque is the maximum torque a motor

develops at the rated voltage and speed without an abrupt loss of speed.

Full-Load Torque. Full-load torque is the torque developed when the

motor is operating with the rated voltage. A typical torque-slip curve is

presented in Fig. 10.4. Locked rotor torque (at standstill) is greater than

full load torque and the motor can be started at full load. Its speed increases

and rotor reaches speed determined by load, frequency and load.

Full-Load Current. Full-load current is the current taken from the

supply line at rated voltage, frequency and load. Three-phase AC motors, for

example, typically requires 600 % starting current and 150 % starting torque.

Fig. 10.4. A typical

torque-slip curve

1.4.

Method of testing

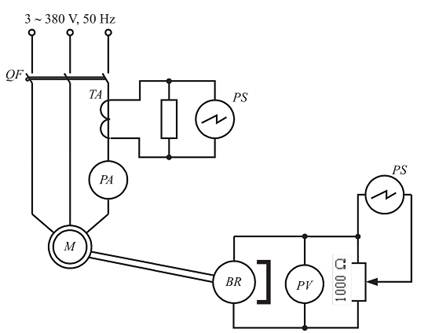

1.

Measurement of

current transient ![]() .

.

2.

Connect the

circuit shown in Fig. 10.5.

Fig. 10.5. Electrical

circuit for measurement of current and speed

Transients

3.

Switch

on and adjust the oscilloscope.

4.

Switch on the

induction motor and get the curve of current transient in the screen.

5.

Measurement of

speed transient ![]() .

.

6.

Connect the

oscilloscope to the terminals of tachogenerator BR load resistor.

7.

Switch on and

adjust the oscilloscope.

8.

Switch on the

induction motor and get the curve, proportional to rotational speed of motor.

9.

Calculate

electromechanical time constant from the obtained curve.

1.5.

Content of report

1. Task of the work and experimental circuit.

2. Experimental curve of current starting transients.

3. Experimental curve of speed starting transients.

4. Calculation of electro-mechanical time constant from

speed starting transient curve.

5. Conclusions.

1.6.

Control questions

1. Explain what elements are denoted as

QF, PA, PV, TA, BR in the electrical circuit.

2. What is called electromechanical time constant?

3. How can you find value of electromechanical speed

constant from the speed transient curve?

4. What current is measure red by ammeter PA?

5. What will happen if resistance TA will be turned off?

6. For what purpose is tachogenerator BR used in the

circuit?