LABORATORY WORK ¹15

CAPACITIVE

PROXIMITY SENSORS. OPTICAL PROXIMITY SENSORS

15.1. Objective

Analyze

characteristics and applications of different position sensor types.

15.2. Task

Use experimental

investigation to obtain sensibility characteristics of different position

sensor types:

·

inductive

proximity sensor;

·

capacitive

proximity sensor;

·

optical

proximity sensor;

·

ultrasonic

proximity sensor.

Investigate the

optical proximity sensor usage for rotation speed measurement.

15.3. Capacitive Proximity

Sensors

Capacitive

proximity switches detect conductive and non-conductive materials that can be

in a solid or liquid state. They serve the purpose of monitoring product levels in

containers, checking contents in filling and packaging systems as well as

detecting, positioning, monitoring and counting objects, e.g. in sequence

control systems, conveyor belts. Used for detecting media such as:

·

solid: wood, ceramic,

glass, paper stacks, plastic, stone, rubber, ice, nonferrous metals, potatoes.

·

liquid: water,

oil, beverages, adhesives, paints.

·

granular:

plastic pellets, granulated products, grain, fodder, wood chip.

·

powder: dyes,

detergents, sand, cement, fertilizer, salt, sugar, flour, coffee.

The function of

the capacitive proximity switch is based on evaluating the influence exerted by

an actuator on the electrical field at the active face of the switch. The

approach of an influencing object increases the capacitance of the capacitor,

which consists of a sensor electrode located behind the active face and the

actuator connected to earth / mass. This increase in capacitance is dependent

on the conductance and the dielectric constant of the actuator as well as its

mass, surface area and its distance from the sensor electrode. The capacitive

limit switch is equipped with an RC oscillator with a gain factor that

increases as a result of the rise in capacitance of the previously described

capacitor to such an extent that oscillation is induced. In limit switches, the

capacitance required to induce oscillation can be determined by the built-in

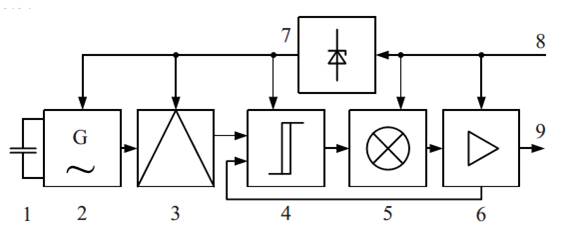

potentiometer intervening in the feedback of the oscillator. The block diagram

of a capacitive proximity sensor is presented in Fig. 15.3.1.

The response

sensitivity, i.e. the sensing distance with a given actuator can be adjusted in

this way. The oscillator output signal is fed to an evaluation circuit that

actuates the switching amplifier. In response to the approach of conductive

material the actuating object and the active face of the sensor form the plates

of a capacitor.

The change in

capacitance and the consequently achievable sensing distance are large. In

response to the approach of nonconductive

material ε > 1 only

the change in the dielectric constant is effective. The increase in capacitance

is less than is the case for conductive materials. The resulting sensing

distance is small. The maxi-mum obtainable switching distance of industrial

capacitive sensors is approximately 60 mm. Reduction factors for some materials

are presented in Table 15.1, the main parameters for the BERNSTEIN

KCN–T12PS/004 M12 capacitive proximity sensor (used in laboratory equipment) –

in Table 15.1.

Fig.

15.3.1. Block diagram of a capacitive proximity sensor

Table 15.1

Target material reduction

factor of capacitive proximity sensor

|

Material |

|

Reduction Factor |

|

All metals |

– |

1.0 |

|

Water |

80.8 |

1.0 |

|

Marble |

8.4 – 14 |

|

|

Glass |

3 – 0.5 |

0.3 – 0.5 |

|

Stack of dry paper |

2 |

|

|

Ceramic |

4.2 – 6.5 |

|

|

Oil |

|

|

Sensitivity of

capacitive proximity sensor with regard to humidity is very high due to the

high dielectric constant of water. They are very sensitive to the dirt also. On

the other hand, they can be used for detection of objects through a

non-metallic wall. The wall thickness in this case should be less than 4 mm and

the dielectric constant of the material to be detected should be higher by a

factor of 4 than that of the wall. Capacitive proximity sensors can be used for

monitoring the winding of electrical wires and cables, because they react to

copper containing electrical wires or cables of relatively small diameter,

whereas inductive proximity sensors react at a smaller switching distance or

not at all.

Optical Proximity Sensors

Optical

proximity sensors use light beam for detection of objects. Red or infrared

light is used for this purpose. Semiconductor light emitting diodes (LEDs) or

lasers are a particularly reliable source of red and infrared light. They are

small and robust, have a long service life and can be easily modulated.

Photodiodes or pho-totransistors are used as receiver elements. When adjusting

optical proximity sensors, red light has the advantage that it is visible in

contrast to infrared light. Besides, polymer optic cables can easily be used in

red wavelength range because of their reduced light attenuation. Infrared (non

visible) light is used in instances, where increased light performance is

required in order to span greater distances for example. Furthermore, infrared

light is less susceptible to interference (ambient light). With both types of

optical proximity sensor, additional suppression of external light influences

is achieved by means of modulating the optical signal. The receiver (with the

exception of through-beam sensors) is tuned to the pulse of the emitter. With

through-beam sensors an electrical band-pass is used in the receiver.

Particularly in the case of infrared light, the use of daylight filters further

improves insensitivity to ambient light.

Usually the 660 nm wavelength emitters are used for

visible red beam sensors with fibreoptic connection and 880 nm – for infrared sensors without

fibreoptic.

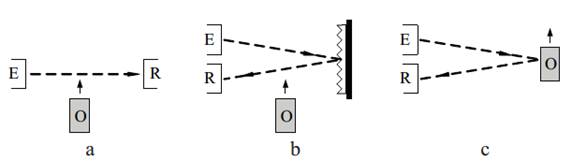

Depending to the

light beam path optical proximity sensors can be divided into barriers

(through-beam and retro-reflective) and diffuse sensors (Fig. 15.3.2).

Fig. 15.3.2. Optical

proximity sensors: a – through-beam; b – retro-reflective;

c – diffuse; where E –

emitter; R – receiver; O – object

Through-beam

sensors consist of

separately assembled emitter and receiver components whereby wide sensing

ranges can be achieved. For the interruption of the light beam to be evaluated,

the cross-section of the active beam must be covered. The object should permit

only minimum penetration of light, but may reflect any amount of light. These

sensors have enhanced reliability because of permanent light during

non-operation, wide range, can detect small objects at large distances, are

suitable for aggressive environment, good positioning accuracy, but two

separate proximity sensor modules (emitter and receiver) and separate

electrical connections are required, failure of the emitter is evaluated as «object present» (important with accident prevention applications).

Retro-reflective

sensors have light emitter

and light receiver installed in one single housing. An additional reflector is required.

Interruption of the light beam is evaluated. Interruption of the light beam

must not be compensated by direct or diffuse reflection of an object.

Transparent, bright or shiny objects may in some cases remain undetected.

Mirroring objects must be positioned in such a manner that the reflecting beam

does not impinge on the receiver. Failure of the emitter is evaluated as

«object present» too.

Diffuse sensors have the emitter and receiver fitted in the

same housing too. The object diffusely reflects a percentage of the emitted

light thereby activating the receiver. The switching distance largely depends

on the reflectivity of the object. The size, surface, shape, density and color

of the object as well as the angle of impact determine the intensity of the

diffused light so that as a rule only small distances within a range of a few

decimeters can be scanned. The background must absorb or deflect the light

emission, i.e. when an object is not present, the reflected light beam must be

clearly below the response threshold of the receiving circuit. The right

sensivity adjustment is very important for these sensors. Failure of the

emitter is evaluated as «no object present». Transparent and non-reflective

(black) object recognition is complicated. Different material sensivity

correction factors are presented in Table 15.2.

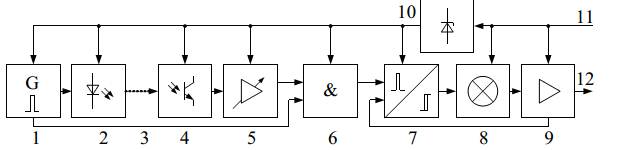

Usually the

emitter and receiver pulse sinchronization is implemented for better influence

cancelling. Typical optical sensor block diagram is presented in Fig. 15.3.3.

Table 15.2

Target material correction

factors for diffuse optical proximity sensor

|

Material |

Correction Factor |

|

Cardboard, white |

1.0 |

|

Expanded polystyrene, white |

1.0 – 1.2 |

|

Metal, shiny |

1.2 – 2.0 |

|

Wood, coarse |

0.4 –0.8 |

|

Cotton material, white |

0.5 – 0.8 |

|

PVC, grey |

0.4 – 0.8 |

|

Cardboard, black shiny |

0.3 |

|

Cardboard, black matt |

0.1 |

Fig. 15.3.3.

Block diagram of optical proximity sensors

The main

parameters for FESTO SOE – L series optical proximity sensor with fiber optic

(used in laboratory equipment) are presented in Table 15.2. Sensors without

fiber optic have very similar characteristics, too.

15.4. Method of testing

1.

Install the

capacitive proximity sensor (looks like blue plastic screw with wiring) on a

testbench to the measuring scale as shown in Fig. 14.4.1 and adjust the zero

position.

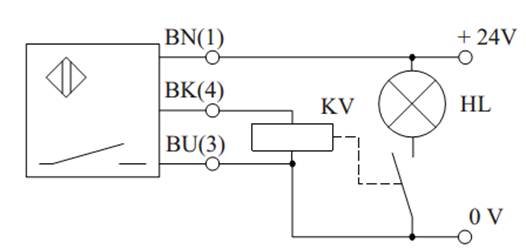

2.

Connect the

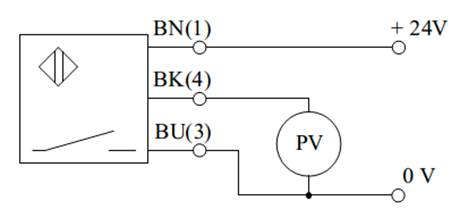

sensor to a power supply and a load according to the scheme at Fig. 15.4.1,

using relay and indication units.

Fig. 15.4.1. Sensor

connection diagram

3.

Perform the

sensor switching distance measurements: for each of four provided material

plates (check the material!) find distances x1

– switch-off point moving from sensor; x2 – switch-on point moving to the sensor; ![]() – hysteresis.

Write the obtained results write in Table 15.3.

– hysteresis.

Write the obtained results write in Table 15.3.

Table 15.3

Sensor testing results

|

Material |

|

|

|

|

Iron |

|

|

|

|

Aluminium |

|

|

|

|

Copper |

|

|

|

|

Plastic |

|

|

|

4.

Perform

steps 1 to 3 for inductive and optical sensor.

Fig. 15.4.2. Ultrasonic

sensor connection diagram

5.

Perform the

ultrasonic sensor test: connect it according to the schematic at Fig. 15.4.2,

and measure the output voltage moving the obstacle (perpendicular book) in

front of the sensor every 5 cm till 1

m. Make a reliance graph.

6.

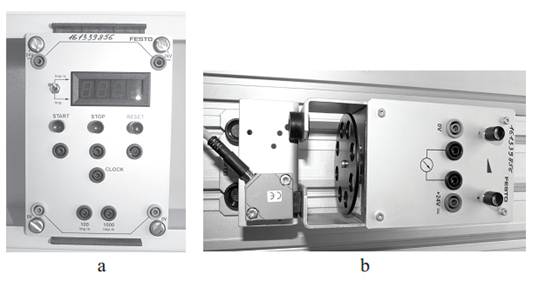

Perform a motor

shaft rotation speed measurement using an optical retro-reflective proximity

sensor. Take a look at Fig. 15.4.3, and make connections: connect power to the

counter, motor and sensor; connect voltmeter to the motor unit control output;

connect sensor output to «CLOCK» input of counter unit. Put the counter unit

switch to the «imp. / s» position. Take a counter marks every 1V motor control voltage increase and put

them into Table 15.4. Calculate the rotation speed for each value using

formula:

![]() [rpm]

[rpm]

where: N – counter indication; n – pulse number per rotation (count the

holes on the disc). Make rotation speed ω

dependence to the control voltage chart.

Fig. 15.4.3. Motor shaft

rotation speed measurement equipment:

a – counter

unit; b – motor unit with installed optical sensor

Table 15.4

Rotation speed

measurement results

|

Control voltage, V |

Counter indication, |

Rotation speed, rpm |

|

|

|

|

15.5. Content of

Report

1.

Objective, task

and model of the laboratory work.

2.

Work results

(connection diagrams, tables and charts).

3.

Conclusions.

15.6. Control

questions

1.

What does

«proximity sensor» mean?

2.

Explain

operation principle of inductive proximity sensor.

3.

What are the

main characteristics of inductive proximity sensor?

4.

Explain

operation principle of capacitive proximity sensor.

5.

What are the

main characteristics of capacitive proximity sensor?

6.

Explain

operation principles of optical proximity sensor.

7.

What are the

main characteristics of optical proximity sensor?

8.

Explain

operation principles of ultrasonic proximity sensor.

9.

What are the

main characteristics of ultrasonic proximity sensor?

10. Find three application examples for each mentioned

sensor type.