LABORATORY WORK ¹ 3

INVESTIGATION INTO

SEPARATELY EXCITED DIRECT CURRENT MOTORCHARACTERISTICS

1.1.

Objectives

Analyze properties and obtain torque-speed characteristics of separately

excited direct current motor using Matlab-Simulink.

1.2.

Task

Use simulation

to obtain characteristics of separately ex-cited direct current (DC) motor:

·

without

additional resistance in the armature;

·

with additional

resistance in the armature;

·

at reduced

supply voltage.

1.3.

Direct current motors

An electric

machine is a reversible energy converter. The same electric machine can work as

an electric motor or a generator of electrical energy. Electric motors are used

in drives of technological machines (fans, pumps, compressors, etc.) or in

drives of different technological equipment. Modern technological machines need

electric motors with flexible speed and torque control and high efficiency.

Electrical and

magnetic circuits are two basic components of all electric machines. In order

to achieve a higher efficiency of a ma-chine, the magnetic circuit must have a

higher magnetic conductivity (lower reluctance) and the electrical circuit – a

higher electrical conductivity (lower resistance). Therefore magnetic circuits

are made of ferromagnetic materials and windings of machines are made of cop-per.

To suppress the eddy currents, magnetic circuits of AC machines are made from

thin insulated sheets of steel. The magnetic circuit of DC machines consists of

massive steel and permanent magnets. Important component of magnetic circuit is

the air gap between the stator and the rotor of the machine. For higher

efficiency, the air gap must be minimized.

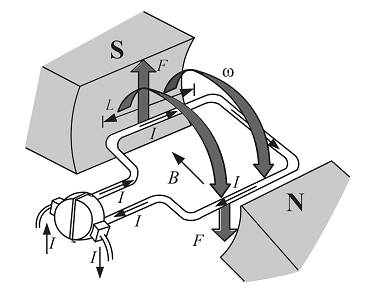

The basic

elements of a DC machine are the rotating coil, means for the production of

flux, and the commutator-brush arrangement.

In a practical

DC machine the coil is replaced by the armature winding mounted on cylindrical

magnetic structure. The flux is pro-vided by the field winding wound on field

poles or permanent magnets windings. Some machines carry more than one separate

field winding on the same core. The excitation winding or permanent magnets on

the poles of the machine generate magnetic field in DC machine shown in Fig.

3.1. The poles (N, S) are fixed to

the yoke of the machine. The yoke is a part of the magnetic core and housing of

the machine. The part of the machine, where magnetic field is generated, is

called an inductor.

Fig. 3.1. Principle of

DC motor operation

The field poles,

mounted on the stator, carry the field windings. Some machines carry more than

one separate field winding on the same core. The armature winding is placed on

the rotating member, the rotor, and the field winding is on the stationary member,

the stator, of DC machine. The schematic of Fig. 3.1 shows most of the

important parts of DC machine. The current-carrying conductors of the armature

are moving in this magnetic field. Continuous rotating of the armature is

possible when the direction of the current is commutated according to the

position of the conductors in relation to the pole. This process is realized by

a commutator that consists of copper contacts and sliding carbon brushes. The

commutator is made of hard-drawn copper segments insulated from one another by

mica. The armature windings are connected to the commutator segments or bars,

over which the carbon brushes slide and serve as leads for electrical

connection.

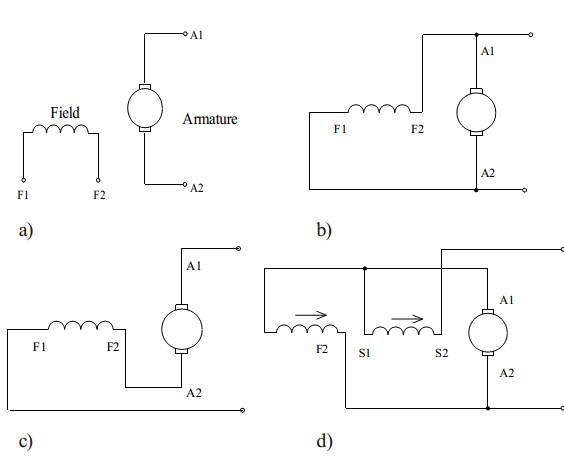

Fig. 3.2. Classification

of DC machines: a) separately excited,

b) shunt, c) series, d)

cumulative compound

Conventional DC

machines having a set of field windings can be classified on the basis of

mutual electrical connections between the field and armature windings, as shown

in Fig. 3.2. These inter-connections of field and armature windings essentially

determine the machine’s operating characteristics.

Performance equations

The three

quantities of the greatest interest in evaluating the performance of a DC

machine are: the induced EMF, electromagnetic torque developed by the machine,

and speed.

The voltage

(EMF) induced in the armature winding depends on Z – the number of active conductors on armature; a – the number of parallel paths in

armature winding; p – the number of

field poles; F – flux per pole, Wb, and n – speed of rotation of the armature, revolutions per minute

(rpm); Back EMF E is calculated as:

![]() (3.1)

(3.1)

For the torque production we must have a current through the armature,

as this current interacts with the field produced by the field winding. If Ia is the current and E is the voltage induced in the

armature, assuming that this entire electric power is transformed to mechanical

form, we can write:

![]() (3.2)

(3.2)

Where Te is

electromagnetic torque developed by the armature and w is its angular velocity in radians per second. The speed n in rpm (revolutions per minute) and ω in rad/s are related as:

![]() (3.3)

(3.3)

From Eqs. (3.1) and (3.3) we obtain:

![]() (3.4)

(3.4)

which can be written as:

![]() (3.5)

(3.5)

or

![]() (3.6)

(3.6)

where

![]() (3.7)

(3.7)

Equation (3.6) indicates that torque delivered by the

motor at constant field flux depend just on armature current. At steady state

operation torque, delivered by motor is equal to load torque.

DC machine operating as a motor will have an EMF

induced while rotating in a magnetic field and will develop a torque if the

armature carries a current.

Referring to Fig. 3.2 a which shows the equivalent circuit of a separately excited DC

motor running at speed n while taking

an armature current Ia, at voltage V we have from this circuit:

![]() (3.8)

(3.8)

1.4.

Method of testing

1.

Speed –torque characteristic ![]() , at

, at ![]() and

and ![]()

2.

Enter the indicated or calculated values of motor parame-ters to the model

blocks. The torque-speed characteristic is obtained by changing load torque by

the indicated step and measuring rotation speed of armature.

3.

Speed-torque characteristic ![]() , at the reduced armature voltage:

, at the reduced armature voltage: ![]() and

and ![]()

4.

Enter to model blocks calculated or indicated values of pa-rameters.

5.

Change the motor load by the indicated step and measure torque and

armature speed.

6.

Put

the obtained results in Table 3.1.

Table 3.1.

Speed torque characteristics at reduced voltage

|

|

0 |

0.2 |

0.4 |

0.6 |

0.8 |

1 |

1.2 |

|

T, N |

|

|

|

|

|

|

|

|

w, rad/s |

|

|

|

|

|

|

|

7.

Speed-torque characteristic ![]() at the rated armature voltage:

at the rated armature voltage: ![]() and

and ![]()

8.

Enter to the model blocks calculated or indicated values.

9.

This characteristic is simulated by changing motor load torque by

appropriate step and measuring speed of armature.

10.

Put the obtained results to Table 3.2.

Table 3.2

Data of

speed-torque characteristic at the increased armature resistance

|

x |

0 |

0.2 |

0.4 |

0.6 |

0.8 |

1 |

1.2 |

|

T, N |

|

|

|

|

|

|

|

|

w, rad/s |

|

|

|

|

|

|

|

Plot speed-torque characteristics ![]() in one reference frame according to the data of Table 3.1, Table 3.2.

in one reference frame according to the data of Table 3.1, Table 3.2.

1.5.

Content of Report

1.

Objective, task and model of the laboratory work.

2.

Work results (tables of simulation results and characteristics).

3.

Conclusions.

1.6. Control questions

1.

Graphical and alphabetical notation of motor windings.

2.

What speed is called no-load speed of rotation?

3.

What dependence is called speed-torque characteristic?

4.

What dependence is called speed regulation characteristic

5.

On what parameters does the motor starting current depend?

6.

What technique can be used to change the motor rotation speed?