LECTURE ¹15

CNC PROGRAMMING AND INDUSTRIAL

ROBOTICS. CNC PROGRAMMING: FUNDAMENTALS

15.1. CNC

PROGRAMMING: FUNDAMENTALS

CNC part program contains a

combination of machine tool code and machine-specific instructions. It consists of:

·

information

about part geometry;

·

motion

statements to move the cutting tool;

·

cutting speed;

·

feed;

·

auxiliary

functions such as coolant on and off, spindle direction.

In this lecture, first we

will understand the coordinate systems of the machine tools and how they work.

CNC Machine Tool

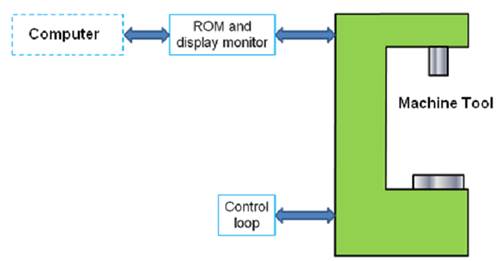

Figure 15.1.1. Schematic of a CNC machine Tool

Figure 15.1.1 shows a schematic of a machine tool controlled by

a computer. It consists of a Machine Control Unit (MCU) and machine tool

itself. MCU, a computer is the brain of a CNC machine tool. It reads the part

programs and controls the machine tools operations. Then it decodes the part

program to provide commands and instructions to the various control loops of

the machine axes of motion. The details regarding the construction and working

of mechatronics based system have already been studied in last lectures. CNC

systems have a limitation. If the same NC program is used on various machine

tools, then it has to be loaded separately into each machine. This is time

consuming and involves repetitive tasks. For this purpose direct numerical

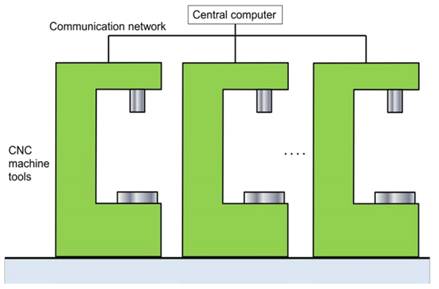

control (DNC) system is developed. Figure 15.1.2 shows the schematic of a DNC system. It consists of a

central computer to which a group of CNC machine tools are connected via a

communication network. The communication is usually carried out using a

standard protocol such as TCP/IP or MAP. DNC system can be centrally monitored

which is helpful when dealing with different operators, in different shifts,

working on different machines.

Fig. 15.1.2. Direct numerical

control (DNC) system

15.2. AXES OF

CNC MACHINE TOOL

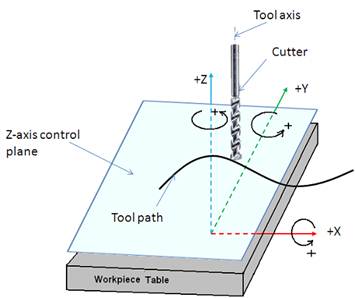

Fig. 15.2.1. Axes of motion of a machine

tool

In CNC machine tool, each

axis of motion is equipped with a driving device to replace the hand wheel of the

conventional machine tool. A axis of motion is defined as an axis where

relative motion between cutting tool and workpiece occurs. The primary axes of

motion are referred to as the X, Y, and Z axes and form the machine tool XYZ

coordinate system. Figure 15.2.1 shows the

coordinate system and the axes of motion of a typical machine tool.

Conventionally machine tools are designated by the number of axes of motion

they can provide to control the tool position and orientation.

If the machine tool can

simultaneously control the tool along two axes, it is classified as a 2-axis

machine. The tool will be parallel and independently controlled along third

axis. It means that machine tool guided the cutting tool along a 2-D contour

with only independent movement specified along the third axis. The Z-axis

control plane is parallel to the XY plane.

15.3. CNC

PROGRAM STRUCTURE

There are four basic terms

used in CNC programming. These are a follows: Character –> Word –> Block –> Program:

Character is the smallest

unit of CNC program. It can have Digit / Letter / Symbol.

Word is a combination of

alpha-numerical characters. This creates a single instruction to the CNC

machine. Each word begins with a capital letter, followed by a numeral. These

are used to represent axes positions, federate, speed, preparatory commands,

and miscellaneous functions.

A program block may contain

multiple words, sequenced in a logical order of processing.

The program comprises of

multiple lines of instructions, ‘blocks’ which will be executed by the machine

control unit (MCU).

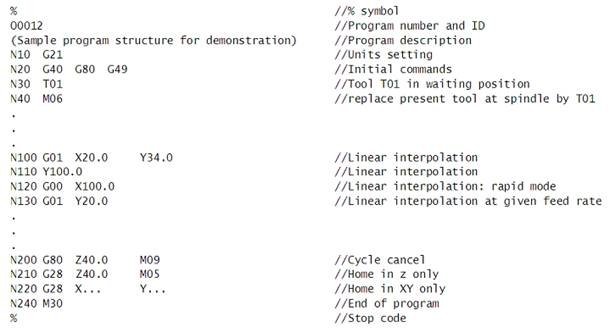

Figure 15.3.1 shows a sample

CNC program. It has basically three sections viz. initial commands section;

main section and end commands section. In the initial commands section, the

program number, its ID, initial safety preparatory codes such as «cancel all the activated cycles by previous program» are to be specified.

In the main section,

commands/instructions related the machine tool axes movements, tool change etc.

At the end, the commands instructing cancellation of cycles, homing the tool

and program end are to be provided.

The address G identifies a

preparatory command, often called G-code. This is used to preset or to prepare

the control system to a certain desired condition or to a certain mode or a

state of operation. For example G01 presets linear interpolation at given feed

but does not move any

axis.

The address M in a CNC

program specifies miscellaneous function. It is also called as machine

function. These functions instruct the machine tool for various operations such

as: spindle rotation, gear range change, automatic tool change, coolant

operation, etc.

Fig. 15.3.1. Sample CNC

program

The G and M codes are

controller manufacturers’ specific. In this course, we will be following the G

and M codes used for FANUC, Japan controller. Other controllers such as

SINUMERIC, MITSUBHISHI etc. are also being used in CNC technology.

It is suggested to the

readers to study the following G and M codes for milling and turning

operations.

15.4. INDUSTRIAL ROBOTICS

Introduction

An industrial robot is a

general-purpose, programmable machine. It possesses some anthropomorphic

characteristics, i.e. human-like characteristics that resemble the human

physical structure. The robots also respond to sensory signals in a manner that

is similar to humans. Anthropomorphic characteristics such as mechanical arms

are used for various industry tasks. Sensory perceptive devices such as sensors

allow the robots to communicate and interact with other machines and to take

simple decisions. The general commercial and technological advantages of robots

are listed below:

Robots are good substitutes

to the human beings in hazardous or uncomfortable work environments.

A robot performs its work cycle

with a consistency and repeatability which is difficult for human beings to

attain over a long period of continuous working.

Robots can be reprogrammed.

When the production run of the current task is completed, a robot can be

reprogrammed and equipped with the necessary tooling to perform an altogether

different task.

Robots can be connected to

the computer systems and other robotics systems. Nowadays robots can be

controlled with wire-less control technologies. This has enhanced the

productivity and efficiency of automation industry.

Robot anatomy

and related attributes

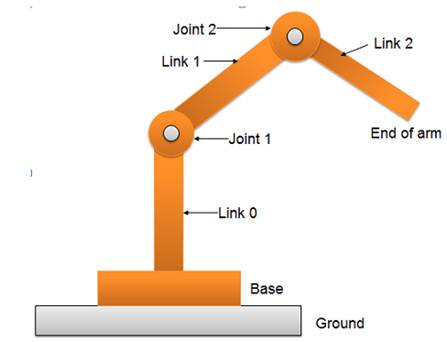

The manipulator of an

industrial robot consists of a series of joints and links. Robot anatomy deals

with the study of different joints and links and other aspects of the manipulator’s

physical construction. A robotic joint provides relative motion between two

links of the robot. Each joint, or axis, provides a certain degree-of-freedom

(dof) of motion. In most of the cases, only one degree-of-freedom is associated

with each joint. Therefore the robot’s complexity can be classified according

to the total number of degrees-of-freedom they possess. Each joint is connected to two links, an input link

and an output link. Joint provides controlled relative movement between the input

link and output link. A robotic link is the rigid component of the robot

manipulator. Most of the robots are mounted upon a stationary base, such as the floor.

From this base, a joint-link numbering scheme may be recognized as shown in

Figure 15.4.1. The robotic

base and its connection to the first joint are termed as link – 0. The first joint in the sequence is joint – 1. Link – 0 is the input link for joint – 1, while the output link from joint – 1 is link – 1– which leads to joint – 2. Thus link 1 is, simultaneously, the output link for joint – 1 and the input link for joint – 2. This joint-link-numbering scheme is further

followed for all joints and links in the robotic systems.

Fig. 15.4.1. Joint-link

scheme for robot manipulator

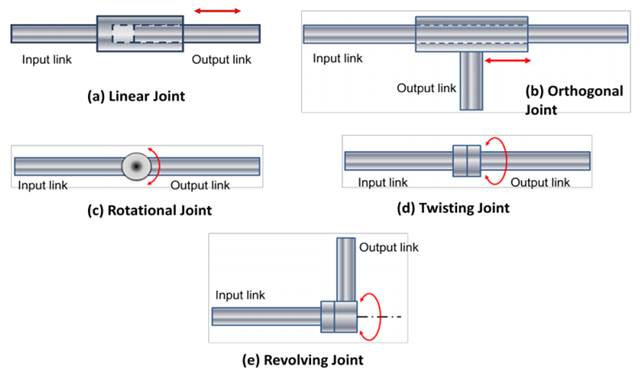

Nearly all industrial robots

have mechanical joints that can be classified into following five types as

shown in Figure 15.4.2.

Fig. 15.4.2. Types of Joints

·

Linear joint

(type L – joint):

The relative movement

between the input link and the output link is a translational sliding motion,

with the axes of the two links being parallel.

·

Orthogonal joint

(type U – joint):

This is also a translational

sliding motion, but the input and output links are perpendicular to each other

during the move.

·

Rotational joint

(type R – joint):

This type provides

rotational relative motion, with the axis of rotation perpendicular to the axes

of the input and output links.

·

Twisting joint

(type T – joint):

This joint also involves

rotary motion, but the axis or rotation is parallel to the axes of the two

links.

·

Revolving joint

(type V – joint, V from

the «v» in revolving):

In this type, axis of input

link is parallel to the axis of rotation of the joint. However the axis of the

output link is perpendicular to the axis of rotation.

Drive systems

Basically three

types of drive systems are commonly used to actuate robotic joints. These are

electric, hydraulic, and pneumatic drives. Electric motors are the prime movers

in robots. Servo-motors or steeper motors are widely used in robotics.

Hydraulic and pneumatic systems such as piston-cylinder systems, rotary vane

actuators are used to accomplish linear motions, and rotary motions of joints

respectively.

Pneumatic drive

is regularly used for smaller, simpler robotic applications; whereas electric

and hydraulic drives may be found applications on more sophisticated industrial

robots. Due to the advancement in electric motor technology made in recent

years, electric drives are generally favored in commercial applications. They

also have compatibility to computing systems. Hydraulic systems, although not

as flexible as electrical drives, are generally used where larger speeds are

required. They are generally employed to carry out heavy duty operations using

robots. The combination of drive system, sensors, and feedback control system

determines the dynamic response characteristics of the manipulator. Speed in

robotic terms refers to the absolute velocity of the manipulator at its

end-of-arm. It can be programmed into the work cycle so that different portions

of the cycle are carried out at different velocities. Acceleration and

deceleration control are also important factors, especially in a confined work

envelope. The robot’s ability to control the switching between velocities is a

key determinant of the manipulator’s capabilities. Other key determinants are

the weight (mass) of the object being manipulated, and the precision that is

required to locate and position the object correctly. All of these determinants

are gathered under the term «speed of response», which is

defined as the time required for the manipulator to move from one point in

space to the next. Speed of response influences the robot’s cycle time, which

in turn affects the production rate that can be achieved.

Stability refers

to the amount of overshoot and oscillation that occurs in the robot motion at

the end-of-arm as it attempts to move to the next programmed location. More

oscillations in the robotic motion lead to less stability in the robotic

manipulator. However, greater stability may produce a robotic system with

slower response times. Load carrying capacity is also an important factor. It

is determined by weight of the gripper used to grasp the objects. A heavy

gripper puts a higher load upon the robotic manipulator in addition to the

object mass. Commercial robots can carry loads of up to 900 kg, while

medium-sized industrial robots may have capacities of up to 45kg.