LECTURE ¹14

PNEUMATIC SYSTEMS. AIR

TREATMENT AND PRESSURE REGULATION

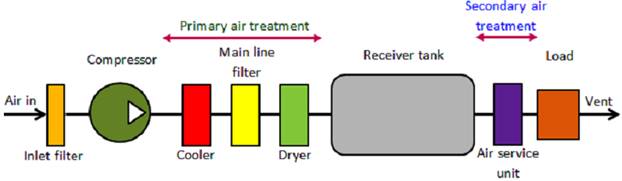

14.1. AIR TREATMENT STAGES

For satisfactory operation

of the pneumatic system the compressed air needs to be cleaned and dried.

Atmospheric air is contaminated with dust, smoke and is humid. These particles

can cause wear of the system components and presence of moisture may cause

corrosion. Hence it is essential to treat the air to get rid of these

impurities. The air treatment can be divided into three stages as shown in

Figure 14.1.1.

Fig. 14.1.1. Stages of air

treatment

In the first stage, the

large sized particles are prevented from entering the compressor by an intake

filter. The air leaving the compressor may be humid and may be at high

temperature. The air from the compressor is treated in the second stage. In

this stage temperature of the compressed air is lowered using a cooler and the

air is dried using a dryer. Also an inline filter is provided to remove any

contaminant particles present. This treatment is called primary air treatment.

In the third stage which is the secondary air treatment process, further

filtering is carried out. A lubricator introduces a fine mist of oil into the

compressed air. This will help in lubrication of the moving components of the

system to which the compressed air will be applied.

Filters

To prevent any damage to the

compressor, the contaminants present in the air need to be filtered out. This

is done by using inlet filters. These can be dry or wet filters. Dry filters

use disposable cartridges. In the wet filter, the incoming air is passed

through an oil bath and then through a fine wire mesh filter. Dirt particles

cling to the oil drops during bubbling and are removed by wire mesh as they

pass through it. In the dry filter the cartridges are replaced during

servicing. The wet filters are cleaned using detergent solution.

Cooler

As the air is compressed,

the temperature of the air increases. Therefore the air needs to be cooled.

This is done by using a cooler. It is a type of heat exchanger. There are two

types of coolers commonly employed viz. air cooled and water cooled. In the air

cooled type, ambient air is used to cool the high temperature compressed air,

whereas in the water cooled type, water is used as cooling medium. These are

counter flow type coolers where the cooling medium flows in the direction

opposite to the compressed air. During cooling, the water vapor present will

condense which can be drained away later.

14.2. MAIN LINE

FILTER

These filters are used to

remove the water vapors or solid contaminants present in the pneumatic systems

main lines. These filters are discussed in detail as follows.

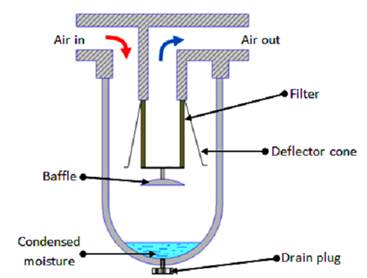

Air filter and

water trap

Air filter and water trap is

used to:

·

prevent any

solid contaminants from entering in the system;

·

condense and

remove water vapor that is present in the compressed air.

Fig. 14.2.1. Air filter and

water trap

The filter cartridge is made

of sintered brass. The schematic of the filter is shown in Fig. 14.2.1. The

thickness of sintered cartridge provides random zigzag passage for the air to

flow-in which helps in arresting the solid particles. The air entering the

filter swirls around due to the deflector cone. The centrifugal action causes

the large contaminants and water vapor to be flung out, which hit the glass

bowl and get collected at the bottom. A baffle plate is provided to prevent the

turbulent air from splashing the water into the filter cartridge. At the bottom

of the filter bowl there is a drain plug which can be opened manually to drain

off the settled water and solid particles.

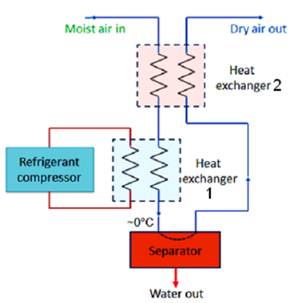

Refrigerated

dryers

Fig. 14.2.2. Refrigerated

dryers

It consists of two heat

exchangers, refrigerant compressor and a separator. The system circuitry is

shown in Figure 14.2.2. The dryer

chills the air just above 0 °C which condenses the water vapor. The condensate

is collected by the separator. However such low temperature air may not be

needed at the application. Therefore this chilled air is used to cool the high

temperature air coming out from the compressor at heat exchanger 2. The

moderate temperature dry air coming out from the heat exchanger 2 is then used

for actual application; whilst the reduced temperature air from compressor will

further be cooled at heat exchanger 1. Thus, the efficiency of the system is

increased by employing a second heat exchanger.

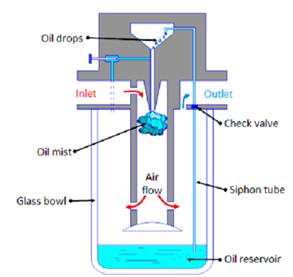

14.3. LUBRICATORS

Fig. 14.3.1. Air lubricator

The compressed air is first

filtered and then passed through a lubricator in order to form a mist of oil

and air to provide lubrication to the mating components. Figure 14.3.1 shows

the schematic of a typical lubricator. The principle of working of venturimeter

is followed in the operation of lubricator. The compressed air from the dryer

enters in the lubricator. Its velocity increases due to a pressure differential

between the upper and lower changer (oil reservoir). Due to the low pressure in

the upper chamber the oil is pushed into the upper chamber from the oil

reservoir through a siphon tube with check valve. The main function of the

valve is to control the amount of oil passing through it. The oil drops inside

the throttled zone where the velocity of air is much higher and this high

velocity air breaks the oil drops into tiny particles. Thus a mist of air and

oil is generated. The pressure differential across chambers is adjusted by a

needle valve. It is difficult to hold an oil mixed air in the air receiver as

oil may settle down. Thus air is lubricated during secondary air treatment

process. Low viscosity oil forms better mist than high viscosity oil and hence

ensures that oil is always present in the air.

14.4. PRESSURE REGULATION

In pneumatic systems, during

high velocity compressed air flow, there is flow-dependent pressure drop

between the receiver and load (application). Therefore the pressure in the

receiver is always kept higher than the system pressure. At the application

site, the pressure is regulated to keep it constant. There are three ways to

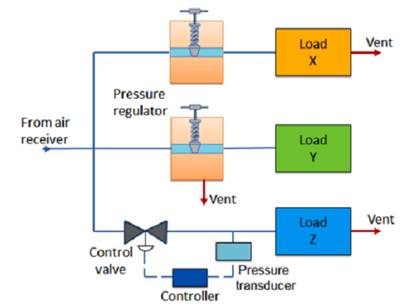

control the local pressure, these are shown in Figure 14.4.1.

Fig. 14.4.1. Types of pressure regulation

·

In the first

method, load X vents the air into atmosphere continuously. The pressure

regulator restricts the air flow to the load, thus controlling the air

pressure. In this type of pressure regulation, some minimum flow is required to

operate the regulator. If the load is a dead end type which draws no air, the

pressure in the receiver will rise to the manifold pressure. These type of regulators

are called as «non-relieving

regulators», since the air

must pass through the load.

·

In the second

type, load Y is a dead end load. However the regulator vents the air into

atmosphere to reduce the pressure. This type of regulator is called as «relieving regulator».

·

The third type

of regulator has a very large load Z. Therefore its requirement of air volume

is very high and can’t be fulfilled by using a simple regulator. In such cases,

a control loop comprising of pressure transducer, controller and vent valve is

used. Due to large load the system pressure may rise above its critical value.

It is detected by a transducer. Then the signal will be processed by the

controller which will direct the valve to be opened to vent out the air. This

technique can be also be used when it is difficult to mount the pressure

regulating valve close to the point where pressure regulation is needed.

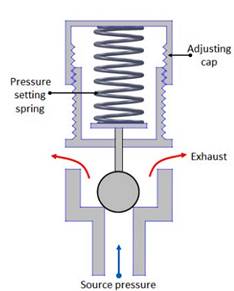

14.5. RELIEF VALVE

Relief valve is the simplest

type of pressure regulating device. The schematic of its construction and

working is shown in the Figure 14.5.1. It is used as a backup device if the

main pressure control fails. It consists of ball type valve held on to the

valve seat by a spring in tension. The spring tension can be adjusted by using

the adjusting cap. When the air pressure exceeds the spring tension pressure

the ball is displaced from its seat, thus releasing the air and reducing the

pressure. A relief is specified by its span of pressure between the cracking

and full flow, pressure range and flow rate. Once the valve opens (cracking

pressure), flow rate depends on the excess pressure. Once the pressure falls

below the cracking pressure, the valve seals itself.

Fig. 14.5.1. Relief valve

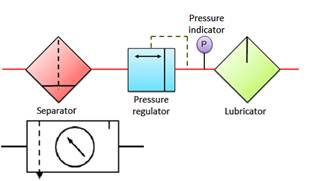

Service units

During the preparation of

compressed air, various processes such as filtration, regulation and

lubrication are carried out by individual components. The individual components

are: separator/filter, pressure regulator and lubricator. Preparatory functions

can be combined into one unit which is called as «service unit». Figure 14.5.2 shows symbolic representation of various processes

involved in air preparation and the service unit.

Fig. 14.5.2. Service unit components and service unit symbol