LECTURE ¹9

DRIVES

AND MECHANISMS. STEPPER MOTORS AND SERVO MOTORS

9.1.

STEPPER MOTOR AND SERVOMOTOR

A stepper motor is a

pulse-driven motor that changes the angular position of the rotor in steps. Due

to this nature of a stepper motor, it is widely used in low cost, open loop

position control systems.

Servomotors are special

electromechanical devices that produce precise degrees of rotation. A servo

motor is a DC or AC or brushless DC motor combined with a position sensing

device. Servomotors are also called control motors as they are involved in

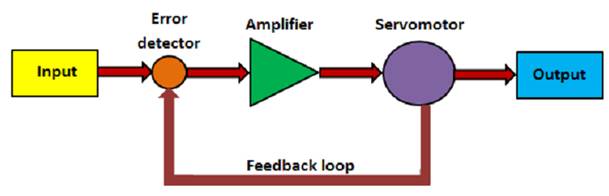

controlling a mechanical system. The servomotors are used in a closed-loop

servo system as shown in Figure 9.1.1. A reference input is sent to the servo

amplifier, which controls the speed of the servomotor. A feedback device is

mounted on the machine, which is either an encoder or resolver. This device

changes mechanical motion into electrical signals and is used as a feedback.

This feedback is sent to the error detector, which compares the actual

operation with that of the reference input. If there is an error, that error is

fed directly to the amplifier, which will be used to make necessary corrections

in control action. In many servo systems, both velocity and position are

monitored. Servomotors provide accurate speed, torque, and have ability of

direction control.

Fig. 9.1.1. Servo system

block diagram

DC servomotors

DC operated servomotors are

usually respond to error signal abruptly and accelerate the load quickly. A DC

servo motor is actually an assembly of four separate components, namely:

·

DC motor;

·

gear assembly;

·

position-sensing

device;

·

control circuit.

AC servo motor

In this type of motor, the

magnetic force is generated by a permanent magnet and current which further

produce the torque. It has no brushes so there is little noise/vibration. This

motor provides high precision control with the help of high resolution encoder.

The stator is composed of a core and a winding. The rotor part comprises of

shaft, rotor core and a permanent magnet. Digital encoder can be of optical or

magnetic type. It gives digital signals, which are in proportion of rotation of

the shaft. The details about optical encoder have already discussed in Lecture

3.

Àdvantages of servo motors:

·

provides high

intermittent torque, high torque to inertia ratio, and high speeds;

·

work well for

velocity control;

·

available in all

sizes;

·

quiet in

operation;

·

smoother

rotation at lower speeds.

Disadvantages of servo

motors:

Ø

more expensive

than stepper motors;

Ø

require tuning

of control loop parameters;

Ø

not suitable for

hazardous environments or in vacuum;

Ø excessive current can result in partial

demagnetization of dc type servo motor.

9.2. CAMS. CLASSIFICATION

OF CAMS

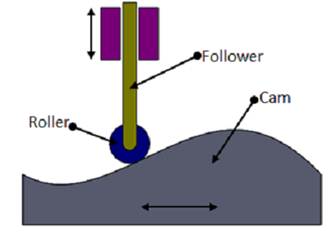

Cams are mechanical devices

which are used to generate curvilinear or irregular motion of mechanical

elements. They are used to convert rotary motion into oscillatory motion or

oscillatory motion into rotary motion. There are two links namely the cam

itself which acts as an input member. The other link that acts as an output

member is called the follower. The cam transmits the motion to the follower by

direct contact. In a cam-follower pair, the cam usually rotates while the

follower translates or oscillates. Complicated output motions which are

otherwise difficult to achieve can easily be produced with the help of cams.

Cams are widely used in internal combustion engines, machine tools, printing

control mechanisms, textile weaving industries, automated machines etc.

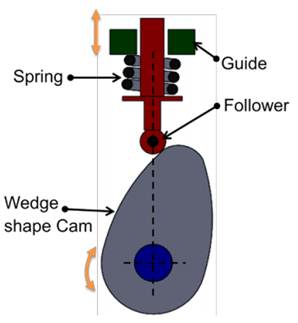

Necessary elements of a cam

mechanism are shown in Figure 9.2.1.

·

a driver member

known as the cam;

·

a driven member

called the follower;

·

a frame which

supports the cam and guides the follower.

Fig. 9.2.1. Cam mechanism

Classification of cams

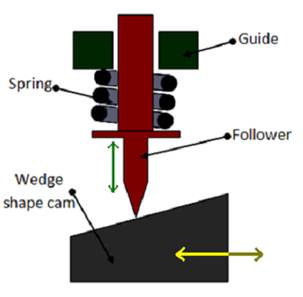

Wedge and Flat Cams

A wedge cam has a wedge of

specified contour and has translational motion. The follower can either

translate or oscillate. A spring is used to maintain the contact between the cam

and the follower. Figure 9.2.2 shows the

typical arrangement of Wedge cam.

Fig. 9.2.2. Wedge cam

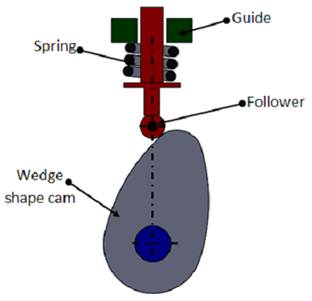

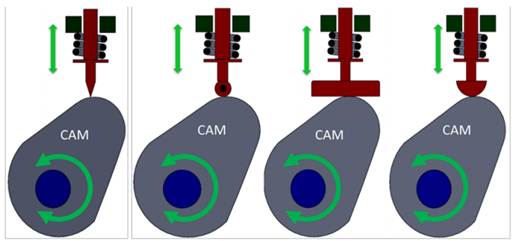

Plate cam

In this type of cams, the

follower moves in a radial direction from the centre of rotation of the cam

(Figure 9.2.3). They are

also known as radial or disc cam. The follower reciprocates or oscillates in a

plane normal to the cam axis. Plate cams are very popular due to their

simplicity and compactness.

Fig. 9.2.3. Plate cam

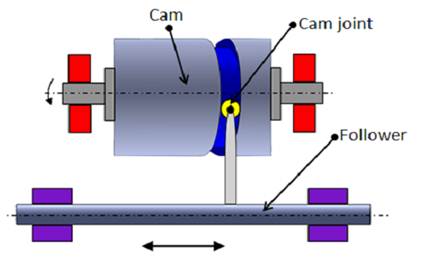

Cylindrical cam

Here a cylinder has a

circumferential contour cut in the surface and the cam rotates about its axis

(Figure 9.2.4). The

follower motion is either oscillating or reciprocating type. These cams are

also called drum or barrel cams.

Fig. 9.2.4. Cylindrical cam

Classification

of followers

Followers can be classified

based on:

·

type of surface

contact between cam and follower;

·

type of follower

motion;

·

line of motion

of followers.

Classification

based on type of surface contact between cam and follower

Figure 9.2.5 shows the schematics of various types of followers

used cam mechanisms.

Fig. 9.2.5. Types of

follower based on the surface in contact

Knife edge follower

The contacting end of the

follower has a sharp knife edge. A sliding motion exists between the contacting

cam and follower surfaces. It is rarely used in practice because the small area

of contacting surface results in excessive wear.

Roller follower

It consists of a cylindrical

roller which rolls on cam surface. Because of the rolling motion between the

contacting surfaces, the rate of wear is reduced in comparison with Knife edge

follower. The roller followers are extensively used where more space is

available such as gas and oil engines.

Flat face follower

The follower face is

perfectly flat. It experiences a side thrust due to the friction between contact

surfaces of follower and cam.

Spherical face follower

The contacting end of the follower

is of spherical shape which overcomes the drawback of side thrust as

experiences by flat face follower.

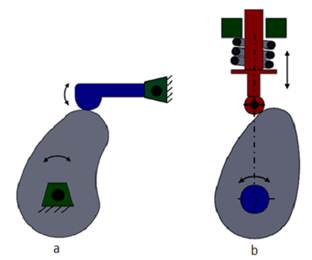

9.3.

CLASSIFICATION BASED ON FOLLOWERS’ MOTION

Figure 9.3.1. shows the types of cams based followers’ motion.

Fig. 9.3.1. Classification of

follower based on motion

Oscillating follower

In this configuration, the rotary motion of the cam is

converted into predetermined oscillatory motion of the follower as shown in

Figure 9.3.1 a).

Translating follower

These are also called as reciprocating follower. The

follower reciprocates in the «guide» as the cam

rotates uniformly as shown in Figure 9.3.1 b).

Applications of

cams

Cams are widely used in

automation of machinery, gear cutting machines, screw machines, printing press,

textile industries, automobile engine valves, tool changers of machine centers,

conveyors, pallet changers, sliding fork in wearhouses etc.

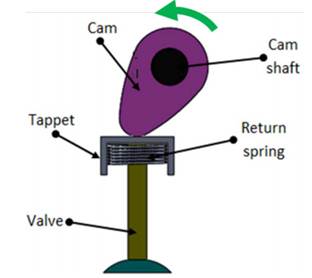

Fig. 9.3.2. Cam in I.C

engine

Cams are also used in I.C

engines to operate the inlet valves and exhaust valves.The cam shaft rotates by

using prime moveres. It causes the rotation of cam. This rotation produces

translatory motion of tappet against the spring. This translatory motion is

used to open or close the valve. The schematic of this operation is shown in

Figure 9.3.2.

Cams in

automatic lathes

The cam shaft is driven by a

motor. The cutting tool mounted on the transverse slide travels to desired

depth and at desired feed rate by a set of plate cams mounted on the cam shaft.

The bar feeding through headstock at desired feed rate is carried out by a set

of plate cams mounted on the camshaft.

Automatic

copying machine

The cam profile can be

transferred onto the work piece by using a roller follower as shown in Figure

9.3.3. The follower can be mounted with a cutting tool. As the cam traverses,

the roller follows the cam profile. The required feature can be copied onto the

workpiece by the movement of follower over the cam profile.

The cam shaft is driven by a

motor. The cutting tool mounted on the transverse slide travels to desired

depth and at desired feed rate by a set of plate cams mounted on the cam shaft.

The bar feeding through headstock at desired feed rate is carried out by a set

of plate cams mounted on the camshaft.

Fig. 9.3.3. Automatic

copying of cam profile

The cam profile can be

transferred onto the work piece by using a roller follower as shown in Figure 9.3.3. The follower can be mounted with a cutting tool. As

the cam traverses, the roller follows the cam profile. The required feature can

be copied onto the workpiece by the movement of follower over the cam profile.