LECTURE ¹ 8

DRIVES AND

MECHANISMS. ELEMENTS OF CNC MACHINE TOOLS: ELECTRIC MOTORS

8.1. DRIVES

Basic function of a CNC

machine is to provide automatic and precise motion control to its elements such

work table, tool spindle etc. Drives are used to provide such kinds of

controlled motion to the elements of a CNC machine tool. A drive system consists

of drive motors and ball lead-screws. The control unit sends the amplified

control signals to actuate drive motors which in turn rotate the ball

lead-screws to position the machine table or cause rotation of the spindle.

Power drives

Drives used in an automated

system or in CNC system are of different types such as electrical, hydraulic or

pneumatic.

·

Electrical

drives:

These are direct current

(DC) or alternating current (AC) servo motors. They are small in size and are

easy to control.

·

Hydraulic drives:

These drives have large

power to size ratio and provide stepless motion with great accuracy. But these

are difficult to maintain and are bulky. Generally they employ petroleum based

hydraulic oil which may have fire hazards at upper level of working temperatures.

Also hydraulic elements need special treatment to protect them against

corrosion.

·

Pneumatic drives:

This drives use air as

working medium which is available in abundant and is fire proof. They are

simple in construction and are cheaper.

However these drives generate low power, have less positioning accuracy

and are noisy.

In CNC, usually AC, DC,

servo and stepper electrical drives are used. The various drives used in CNC

machines can be classified as:

1. spindle drives to provide the main spindle power for

cutting action;

2. feed drives to drive the axis.

Spindle drives

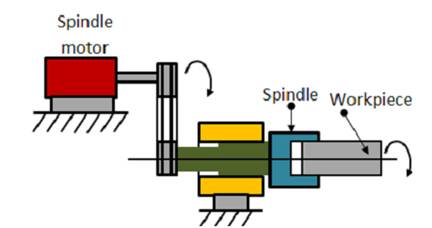

Fig. 8.1.1. Schematic of a

spindle drive

The spindle drives are used

to provide angular motion to the workpiece or a cutting tool. Figure 8.1.1

shows the components of a spindle drive. These drives are essentially required

to maintain the speed accurately within a power band which will enable

machining of a variety of materials with variations in material hardness. The

speed ranges can be from 10 to 20,000 rpm. The machine tools mostly employ DC

spindle drives. But as of late, the AC drives are preferred to DC drives due to

the advent of microprocessor-based AC frequency inverter. High overload

capacity is also needed for unintended overloads on the spindle due to an

inappropriate feed. It is desirous to have a compact drive with highly smooth

operation.

Feed Drives

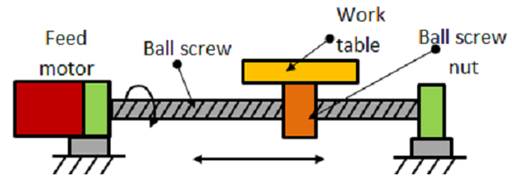

Fig. 8.1.2. Typical feed

drive

These are used to drive the

slide or a table. Figure 8.1.2 shows various elements of a feed drive. The

requirements of an ideal feed drive are as follows:

·

the feed motor

needs to operate with constant torque characteristics to overcome friction and

working forces;

·

the drive speed

should be extremely variable with a speed range of about 1: 20000, which means

it should have a maximum speed of around 2000 rpm and at a minimum speed of 0.1

rpm;

·

the feed motor

must run smoothly;

·

the drive should

have extremely small positioning resolution;

·

other

requirements include high torque to weight ratio, low rotor inertia and quick

response in case of contouring operation where several feed drives have to work

simultaneously.

Variable speed DC drives are

used as feed drives in CNC machine tools. However now-a-days AC feed drives are

being used.

Electrical

drives

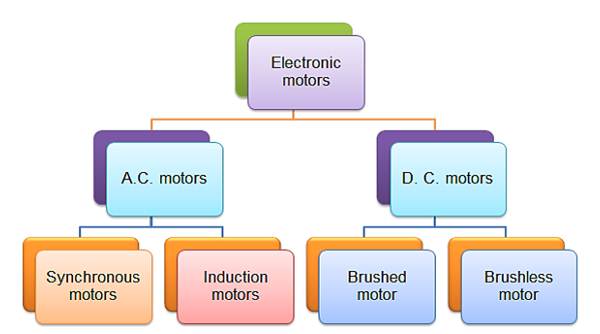

Fig. 8.1.3. Classification

of motors

Electric drives are mostly

used in position and speed control systems. The motors can be classified into

two groups namely DC motors and AC motors (Fig. 8.1.3). In this session we

shall study the operation, construction, advantages and limitations of DC and

AC motors.

8.2. DC MOTORS

A DC motor is a device that

converts direct current (electrical energy) into rotation of an element

(mechanical energy). These motors can further be classified into brushed DC motor and

brushless DC motors.

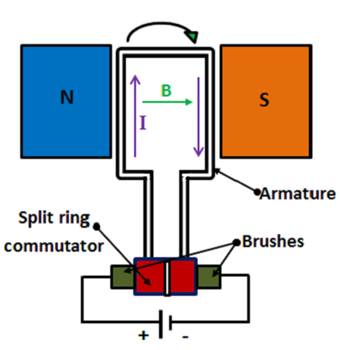

Brush type DC

motor

A typical brushed motor

consists of an armature coil, slip rings divided into two parts, a pair of

brushes and horse shoes electromagnet as shown in Fig. 4.1.4. A simple DC motor has two field poles namely

a north pole and a south pole. The magnetic lines of force extend across the

opening between the poles from north to south. The coil is wound around a soft

iron core and is placed in between the magnet poles. These electromagnets

receive electricity from an outside power source. The coil ends are connected

to split rings. The carbon brushes are in contact with the split rings. The

brushes are connected to a DC source. Here the split rings rotate with the coil

while the brushes remain stationary.

Fig. 8.2.1. Brushed DC motor

The working is based on the

principle that when a current-carrying conductor is placed in a magnetic field,

it experiences a mechanical force whose direction is given by Fleming's

left-hand rule. This field produces a force which turns the armature. This force

is called torque. This torque will cause the armature to turn until its

magnetic field is aligned with the external field. Once aligned the direction

of the current in the windings on the armature reverses, thereby reversing the

polarity of the rotor's electromagnetic field. A torque is once again exerted

on the rotor, and it continues spinning. The change in direction of current is

facilitated by the split ring commutator. The main purpose of the commutator is

to overturn the direction of the electric current in the armature. The

commutator also aids in the transmission of current between the armature and

the power source. The brushes remain stationary, but they are in contact with

the armature at the commutator, which rotates with the armature such that at

every 180° of rotation, the current in the armature is reversed.

Advantages of brushed DC

motor:

·

the design of

the brushed dc motor is quite simple;

·

controlling the

speed of a brush dc motor is easy;

·

very cost

effective.

Disadvantages of brushed DC

motor:

·

high maintenance;

·

performance

decreases with dust particles;

·

less reliable in

control at lower speeds;

·

the brushes wear

off with usage.

Brushless DC

motor

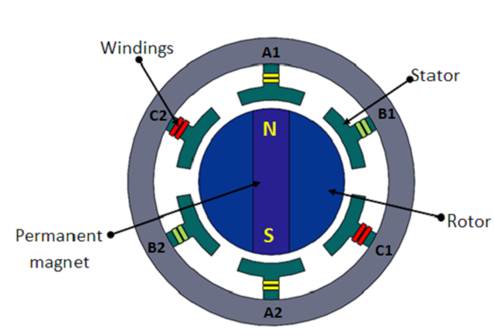

Fig. 8.2.2. Brushless DC

motor

A brushless DC motor has a

rotor with permanent magnets and a stator with windings. The rotor can be of

ceramic permanent magnet type. The brushes and commutator are eliminated and

the windings are connected to the control electronics. The control electronics

replace the commutator and brushes and energize the stator sequentially. Here

the conductor is fixed and the magnet moves (Fig. 8.2.2).

The current supplied to the

stator is based on the position of rotor. It is switched in sequence using

transistors. The position of the rotor is sensed by Hall effect sensors. Thus a

continuous rotation is obtained.

Àdvantages of brushless dc motor:

·

more precise due

to computer control;

·

more efficient;

·

no sparking due

to absence of brushes;

·

less electrical

noise;

·

no brushes to

wear out;

·

electromagnets

are situated on the stator hence easy to cool;

·

motor can

operate at speeds above 10,000 rpm under loaded and unloaded conditions;

·

responsiveness

and quick acceleration due to low rotor inertia.

Disadvantages of brushless

DC motor:

·

higher initial

cost;

·

complex due to

presence of computer controller;

·

brushless dc

motor also requires additional system wiring in order to power the electronic

commutation circuitry.

8.3. AC MOTORS

AC motors convert AC current

into the rotation of a mechanical element (mechanical energy). As in the case

of DC motor, a current is passed through the coil, generating a torque on the

coil. Typical components include a stator and a rotor. The armature of rotor is

a magnet unlike DC motors and the stator is formed by electromagnets similar to

DC motors. The main

limitation of AC motors over DC motors is that speed is more difficult to

control in AC motors. To overcome this limitation, AC motors are equipped with

variable frequency drives but the improved speed control comes together with a

reduced power quality.

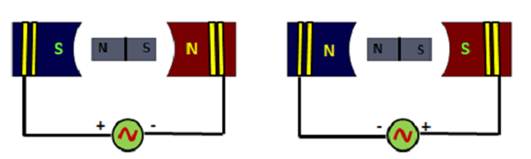

Fig. 8.3.1. AC motor working

principle

The working principle of AC

motor is shown in fig. 4.1.6. Consider the rotor to be a permanent magnet.

Current flowing through conductors energizes the magnets and develops N and S

poles. The strength of electromagnets depends on current. First half cycle

current flows in one direction and in the second half cycle it flows in

opposite direction. As AC voltage changes the poles alternate.

AC motors can be classified

into synchronous motors and induction motors.

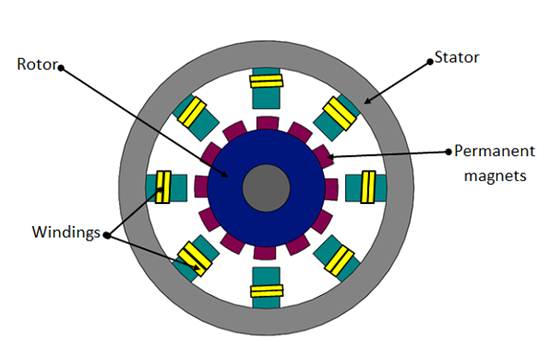

Synchronous

motor

A synchronous motor is an AC

motor which runs at constant speed fixed by frequency of the system. It

requires direct current (DC) for excitation and has low starting torque, and hence

is suited for applications that start with a low load. It has two basic

electrical parts namely stator and rotor as shown in fig. 8.3.2.

The stator consists of a

group of individual wounded electro-magnets arranged in such a way that they

form a hollow cylinder. The stator produces a rotating magnetic field that is

proportional to the frequency supplied. The rotor is the rotating electrical

component. It also consists of a group of permanent magnets arranged around a

cylinder, with the poles facing toward the stator poles. The rotor is mounted

on the motor shaft. The main difference between the synchronous motor and the

induction motor is that the rotor of the synchronous motor travels at the same

speed as the rotating magnet.

Fig. 8.3.2. Synchronous AC

motor

The stator is given a three

phase supply and as the polarity of the stator progressively change the

magnetic field rotates, the rotor will follow and rotate with the magnetic

field of the stator. If a synchronous motor loses lock with the line frequency

it will stall. It cannot start by itself, hence has to be started by an

auxiliary motor.

Induction motor

Induction motors are quite

commonly used in industrial automation. In the synchronous motor the stator

poles are wound with coils and rotor is permanent magnet and is supplied with

current to create fixed polarity poles. In case of induction motor, the stator

is similar to synchronous motor with windings but the rotors’ construction is

different.

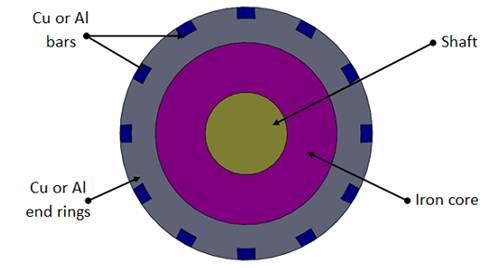

Rotor of an induction motor

can be of two types:

·

a squirrel-cage

rotor consists of thick conducting bars embedded in parallel slots. The bars can be

of copper or aluminum. these bars are fitted at both ends by means end rings as

shown in figure 8.3.3;

·

a wound rotor

has a three-phase, double-layer, distributed winding. The rotor is wound for as

many numbers of poles as the stator. The three phases are wired internally and

the other ends are connected to slip-rings mounted on a shaft with brushes

resting on them.

Induction motors can be

classified into two types:

·

single-phase induction motor: It has one stator winding and a squirrel cage rotor.

It operates with a single-phase power supply and requires a device to start the

motor;

·

three-phase induction motor: The rotating magnetic field is produced by the

balanced three-phase power supply. These motors can have squirrel cage or wound

rotors and are self-starting.

Fig. 8.3.3. Induction motor

rotor

In an induction motor there

is no external power supply to rotor. It works on the principle of induction.

When a conductor is moved through an existing magnetic field the relative

motion of the two causes an electric current to flow in the conductor. In an

induction motor the current flow in the rotor is not caused by any direct

connection of the conductors to a voltage source, but rather by the influence

of the rotor conductors cutting across the lines of flux produced by the stator

magnetic fields. The induced current which is produced in the rotor results in

a magnetic field around the rotor. The magnetic field around each rotor

conductor will cause the rotor conductor to act like the permanent magnet. As

the magnetic field of the stator rotates, due to the effect of the three-phase

AC power supply, the induced magnetic field of the rotor will be attracted and

will follow the rotation. However, to produce torque, an induction motor must

suffer from slip. Slip is the result of the induced field in the rotor windings

lagging behind the rotating magnetic field in the stator windings.

Advantages of AC induction

motors:

·

it has a simple

design, low initial cost, rugged construction almost unbreakable;

·

the operation is

simple with less maintenance (as there are no brushes);

·

the efficiency

of these motors is very high, as there are no frictional losses, with

reasonably good power factor;

·

the control gear

for the starting purpose of these motors is minimum and thus simple and

reliable operation.

Disadvantages of AC

induction motors:

·

the speed

control of these motors is at the expense of their efficiency;

·

as the load on

the motor increases, the speed decreases;

·

the starting

torque is inferior when compared to dc motors.

8.4. STEPPER

MOTOR

A stepper motor is a

pulse-driven motor that changes the angular position of the rotor in steps. Due

to this nature of a stepper motor, it is widely used in low cost, open loop

position control systems.

·

Types of stepper

motors:

Ø

permanent magnet;

Ø

employ permanent

magnet;

Ø

low speed,

relatively high torque.

·

Variable

Reluctance:

Ø

does not have

permanent magnet;

Ø

low torque.

Variable

Reluctance Motor

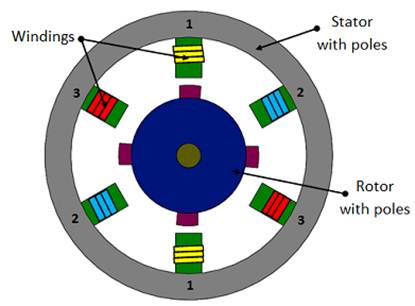

Figure 8.4.1 shows the construction of Variable Reluctance

motor. The cylindrical rotor is made of soft steel and has four poles as shown

in Fig.4.2.1. It has four rotor teeth, 90⁰apart and six stator poles, 60⁰ apart.

Electromagnetic field is produced by activating the stator coils in sequence.

It attracts the metal rotor. When the windings are energized in a reoccurring

sequence of 2, 3, 1, and so on, the motor will rotate in a 30⁰ step angle. In the non-energized condition, there is

no magnetic flux in the air gap, as the stator is an electromagnet and the

rotor is a piece of soft iron; hence, there is no detent torque. This type of

stepper motor is called a variable reluctance stepper.

Fig. 8.4.1. Variable

reluctance stepper motor

Permanent magnet

(PM) stepper motor

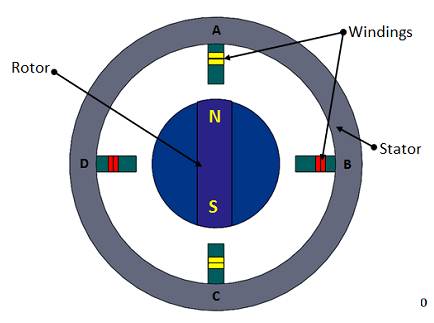

In this type of motor, the

rotor is a permanent magnet. Unlike the other stepping motors, the PM motor

rotor has no teeth and is designed to be magnetized at a right angle to its axis.

Figure 8.4.2 shows a simple,

90⁰ PM motor with four phases (A-D). Applying current to

each phase in sequence will cause the rotor to rotate by adjusting to the

changing magnetic fields. Although it operates at fairly low speed, the PM

motor has a relatively high torque characteristic. These are low cost motors

with typical step angle ranging between 7.5⁰ to 15⁰.

Fig. 8.4.2. Permanent magnet

stepper

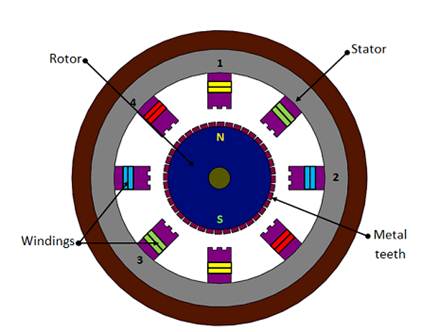

Hybrid stepper

motor

Hybrid stepping motors

combine a permanent magnet and a rotor with metal teeth to provide features of

the variable reluctance and permanent magnet motors together. The number of

rotor pole pairs is equal to the number of teeth on one of the rotor’s parts.

The hybrid motor stator has teeth creating more poles than the main poles

windings (Fig. 8.4.3).

Rotation of a hybrid

stepping motor is produced in the similar fashion as a permanent magnet

stepping motor, by energizing individual windings in a positive or negative

direction. When a winding is energized, north and south poles are created,

depending on the polarity of the current flowing. These generated poles attract

the permanent poles of the rotor and also the finer metal teeth present on

rotor. The rotor moves one step to align the offset magnetized rotor teeth to

the corresponding energized windings. Hybrid motors are more expensive than

motors with permanent magnets, but they use smaller steps, have greater torque

and maximum speed.

Advantages of stepper motors:

·

low cost;

·

ruggedness;

·

simplicity of

construction;

·

low maintenance;

·

less likely to

stall or slip;

·

will work in any

environment;

·

excellent

start-stop and reversing responses.

Fig. 8.4.3. Hybrid stepper

motor

Disadvantages of stepper

motors:

·

low torque

capacity compared to dc motors;

·

limited speed;

·

during

overloading, the synchronization will be broken. vibration and noise occur when

running at high speed.