LECTURE

¹ 7

PROGRAMMABLE LOGIC DEVICES

(PLDS). INTRODUCTION TO MICROPROCESSOR PROGRAMMING

7.1. NUMBER SYSTEM

Number system is

a way of representing the value of any number with respect to a base value.

Number System can be classified on the basis of its «base». Each number

has a unique representation in a number system. Different number systems have

different representation of the same number. In general Binary, Octal, Decimal

and Hexadecimal Number systems are used in microprocessor programming.

Decimal number system to any number

system

Any number in

decimal system can be changed to any other number system by continuously

dividing it by base of the required number system and then writing remainders

after each step in reverse order.

Let us take an

example of converting a decimal number 235 to its binary equivalent. Following

table shows the conversion process as stated above.

Table 7.1.1

Binary representation of (235)10

|

2 |

235 |

|

|

2 |

117 |

1 |

|

2 |

58 |

0 |

|

2 |

29 |

1 |

|

2 |

14 |

0 |

|

2 |

7 |

1 |

|

2 |

3 |

1 |

|

2 |

1 |

1 |

![]() Hence Binary equivalent of (235)10

is (11101011)2.

Hence Binary equivalent of (235)10

is (11101011)2.

Hexadecimal system

This system is

quite extensively used in microprocessor programming. It facilitates much

shorter representation of number in comparison with that obtained by using the

binary number system. Hexadecimal system has a base of 16 and it is easy to

write and remember the numbers and alphabets viz. 0 to 9 and A to F. Table 7.1.2 shows numerals

and alphabets used in hexadecimal system for representation of a number.

Table

7.1.2

Numerals and alphabets used in hexadecimal system

|

Decimal |

Binary |

Hexadecimal |

|

0 |

0000 |

0 |

|

1 |

0001 |

1 |

|

2 |

0010 |

2 |

|

3 |

0011 |

3 |

|

4 |

0100 |

4 |

|

5 |

0101 |

5 |

|

6 |

0110 |

6 |

|

7 |

0111 |

7 |

|

8 |

1000 |

8 |

|

9 |

1001 |

9 |

|

10 |

1010 |

A |

|

11 |

1011 |

B |

|

12 |

1100 |

C |

|

13 |

1101 |

D |

|

14 |

1110 |

E |

|

15 |

1111 |

F |

Example: Let us

convert the number (235)10 to hexadecimal equivalent. Table 7.1.2

shows the conversion of this decimal number.

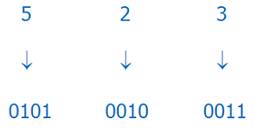

Binary coded decimal (BCD)

BCD code

expresses each digit of a decimal system by its nibble equivalent. It uses 4

bit binary strings to represent the digits 0 to 9. Figure 7.1.1 shows the

representation of number 523 as 010100100011 using BCD system. Due its longer

representation scheme, it is now rarely used in micro-electronics programming.

Fig. 7.1.1. BCD

representation system

Example: (235)10 can be

represented by using PCD as 001000110101.

7.2. LOW LEVEL PROGRAMMING LANGUAGE

Microprocessors

recognize the binary numbers and they operate in binary numbers. Each

microprocessor has its own binary words, meanings and languages. Each machine

has its own set of instructions based on the design of its CPU. Binary language

is called as machine language. English-like words are used to represent the

binary instructions of a machine. This is called as assembly language programs.

The general purpose languages such as BASIC, FORTRAN, C, etc. are called as

high-level languages. The machine language and assembly language are however

specific to a microprocessor, thereforethese are termed as low-level languages.

Assembly language

In assembly

language, a word length is of about eight bits. It is called as a byte.

Assembly language can have 256 combinations of bytes. Thus the language has 256

words. There can be a various patterns of bytes. With the help of electronic

logic gates, these patterns give a specific meaning to each combination of

bytes. These are called as an «instruction». Instructions

are made up of one word or several words.

The set of instructions designed

into the machine makes up the machine language that is specific to each

microprocessor based system viz. micro-computer. Thus we can say, «Machine language

is the binary medium of communication through a designed set of instructions

specific to each computer», «Assembly level

language is a medium of communication with a computer in which programs are

written in mnemonics. An assembly language is specific to a given computer».

Assembly language programming

Assembly

language programming is generally written by using hexadecimal codes. Programs

can be written by using special keyboard equipped with using hex keys. Programs

also have instructions to translate these keys into their equivalent binary

patterns. The data and instructions are stored in prescribed locations in

memory. An operation code is written which accomplishes the intended task(s).

These tasks are carried out on «operand(s)» by the

operation code. 8085 is a typical general purpose microprocessor and has 8-bit

word length. Now, let us learn its architecture, working and programming.

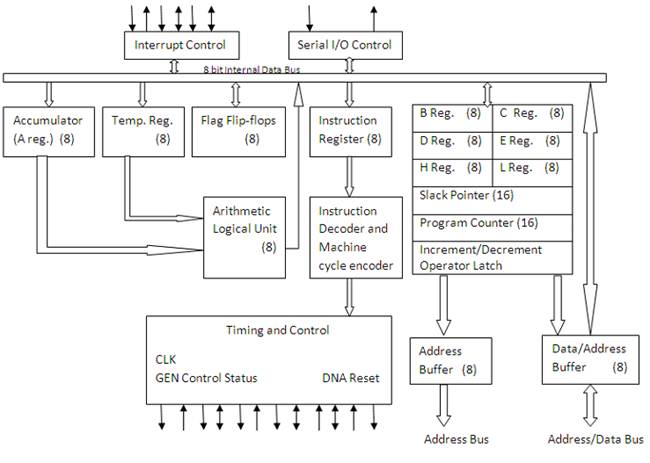

Internal Architecture of 8085 Microprocessor.

Register Array

8085

Microprocessor consists of six registers, one accumulator and a flag register.

The typical architecture is shown in figure 7.2.1.

There are six general-purpose registers B, C, D, E, H, and L, each having

capacity to store 8 bit data. They are combined as BC, DE, HL to perform 16 bit

operations. In addition to this Register array, two 16 bit registers viz. stack

register and program counter are provided. As discussed in the earlier lecture,

the «program

counter» is

employed to sequence the execution of instructions. It always points to the

memory address from which the next byte is to be fetched. Stack Pointer points

to the memory location in R/W (Read and/or write) memory. It is also termed as

a «stack».

Fig. 7.2.1. Architecture of 8085 microprocessor

7.3.

ACCUMULATOR

The accumulator

is 8-bit register (can store 8 bit data). It is a part of arithmetic/logic unit

(ALU). In general, after performing logical or arithmetical operations, result

is stored in accumulator. Accumulator is also identified as Register A.

Flags

ALU of 8085 have

five flip flops whose states (set/reset) are determined by the result data of

other registers and accumulator. They are called as Zero, Carry, Sign, Parity

and Auxiliary-Carry flags:

·

Zero Flag (Z): When an arithmetic operation results in zero, the flip-flop

called the Zero flag - which is set to one.

·

Carry flag (CY): After an addition of two numbers, if the sum in the

accumulator is larger than eight bits, then the flip-flop uses to indicate a

carry called the Carry flag – which is set to one.

·

S-Sign (S): It is set to 1, if bit D7 of the result = 1; otherwise

reset. D7 is the first digit of a binary number.

![]()

|

S |

Z |

|

AC |

|

P |

|

CY |

·

P-Parity (P): If the result has an even number of 1s, the flag is set to

1; for an odd number of 1s the flag is reset.

·

AC-Auxiliary Carry (AC): In an arithmetic operation, when a carry is

generated by digit D3 and passed to digit D4, the AC flag is set. Generally

this flag is used internally for Binary Coded Decimals (BCD).

·

Figure 7.2.1 shows a 8-bit flag register, adjacent to the accumulator.

It is not used as a register. Out of eight bit-positions, five positions are

used to store the outputs of five flip-flops. These flags play an important

role in decision-making process of the microprocessor.

Instruction Register/Decoder

Before execution

of an instruction, it is sent to the Instruction Register. Instruction register

stores current instruction of any program. Decoder takes the instruction from

memory, decodes it and then passes it to the next stage.

Memory Address Register

Memory Address

Register (MAR) holds the address of next instruction to be executed.

Control Generator

In

microprocessor, the Control Generator generates a signal that executes the

operations in accordance to the decoded instructions. In fact it creates a

signal (information) which have details about connections between different

blocks of the microprocessor so that data reaches to the respective place.

Register Selector

Register

selector is basically a logical controller which directs switching between

different registers of microprocessor.

General Purpose Registers

Microprocessor

has few extra registers which can be used to store additional data during a

program.

Programming in 8085

As mentioned in

above section, a simple and very effective substitution to binary codes could

be use of standard English words to complete any task. For example addition of

two numbers can be represented by ADD. Such codes are referred as mnemonic

codes and

that language is called assembly language. Most of the early processers

including 8085, are programmed using mnemonics. However, assembly language

codes should be converted into binary one so that microprocessor can identify

the instructions given to it. This operation is done by Assembler. In assembly

language, instructions are composed of two segments which are as follows:

·

Operation (Op)

Code: It depends on which operation is to be performed. For

example for OR operation, we have Op Code «OR».

·

Operands:

Operand is the object on which the required operation is to be done. Generally

operations are done on data stored in registers.

Classification of Instructions:

·

Data Transfer;

·

Arithmetic;

·

Logical;

·

Program Control.

Data Transfer

1. Load:

It reads content from specified memory location and copies it to specified

register location in CPU.

2. Store:

It copies content of a specified register into specified memory location.

Arithmetic:

1. Add:

It adds contents of a specified memory location to the data in some register;

2. Decrement:

It subtracts 1 from contents of specified location;

3. Compare:

It tells whether contents of a register are greater than, less than or same as

content of specified memory location.

Logical:

1. AND: Instruction carries out Logical AND operation

with the contents of specified memory location and data in some register.

Numbers are ANDed bit by bit.

2. OR:

Instruction carries out Logical OR operation with the contents of specified

memory location and data in some register. Numbers are ORed bit by bit.

3. Logical

Shift: Logical shift instruction involves moving a pattern of bits in the

register one place to left or right by moving a zero in the end of number.

Program Control:

1. Jump:

This instruction changes the sequence in which program steps are carried out.

Normally program counter causes the program to be carried out sequentially in

strict numerical sequence. However, JUMP causes program counter to some other

specified location in the program.

2.

Branch: This is a conditional instruction which might «branch» if «zero» results or «branch» if «plus» results of an

operation. Branch also followed if right conditions occur in the decision

making process.

3.

Halt: This instruction stops all further microprocessor activity.

7.4. PROGRAMMABLE LOGIC

CONTROLLERS

Any computer

having input and output interfaces can be used to control external devices. However most of

the computers are not industrially hardened. Input / Output devices of general-purpose

microcomputers are not engineered to handle line-voltages and currents above

transistor-transistor logic (TTL) levels. Also they are not designed to

with-stand the temperature, humidity, and vibration on shop floors. These

drawbacks of a general purpose computer have been rectified by developing a

Programmable Logic Controller (PLC) with built-in isolation into their inputs

and outputs.

«The programmable

logic controller is defined as a digital electronic device that uses a

programmable memory to store instructions and to implement functions such as

logic, sequencing, timing, counting and arithmetic words to control machines

and processes».

PLCs are

generally used for incorporating automation in open loop systems where

processes are to be performed in a sequential manner. PLCs are used for

automation of assembly lines in industries. They are generally designed for

multiple input multiple output (MIMO) systems. In PLCs, instructions are saved

in nonvolatile memory. Some of the advantages of PLCs are:

·

Cost effective;

·

Flexibility and ability to use similar system for other processes;

·

Programming interface is easier in comparison to other processers;

·

Resistant to impact and vibration;

·

Resistant towards electrical and mechanical noise;

·

Ability to work at high temperatures;

·

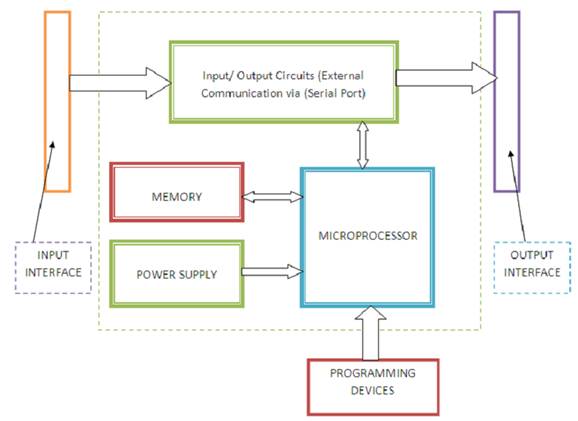

Now let us study the structure and functioning of a PLC.

Figure 7.4.1 shows the

basic elements of a PLC. It is basically a microprocessor based control system.

Microprocessor communicates with the outside world with input/output devives

via a circuitry. This circuitry protects the microprocessor and other elements

of PLC from the high voltages and currents coming to the PLC. Microprocessor

does its basic functions of taking decisions according to the instructions

written in the programs which are stored in the memory. PLC scans a set of

sensor inputs rapidly and repeatedly. Then it evaluates their logic

relationships to defined outputs according to a logic program. At last it sets

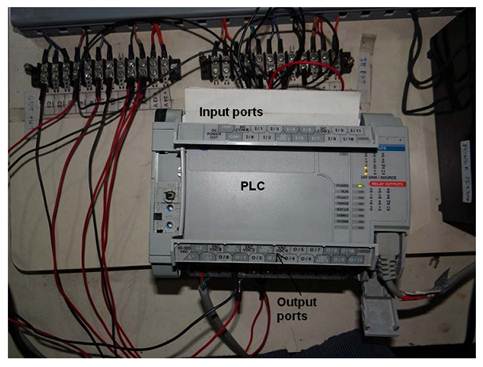

the outputs according to the programmed logic. Figure 7.4.2 shows an

industrial PLC with input and output ports.

Programmable Logic Controller: Structure and Functioning

Fig. 7.4.1. Block diagram of a PLC

Fig. 7.4.2. An Industrial PLC

Programming a PLC:

PLCs are

programmed through concept of ladder logic. In general there exists a graphical

user interface (GUI) to program a PLC that makes it different from other

processers. Ladder logic comprises of two columns. Left column shows input

devices like switches, sensors while in output column is at right side which

shows actuators like cylinders, motors.

This instruction

is called as «examine

on» or «normally opened» as input

functions or storage bits. If the corresponding memory bit is a «1» then the

respective «rung» will

continuously be executed and the corresponding outputs will be energized. Rung

is one of the multiple horizontal programming lines in a ladder logic diagram.

NOTE: Other

factors may also affect rung simultaneously.

If the

corresponding bit is «0» then the rung

will not be executed continuously and outputs will be de-energized. If this

instruction is used as input bit, its status should be according to the status

of the real world input devices connected to the input table by identical

addresses.

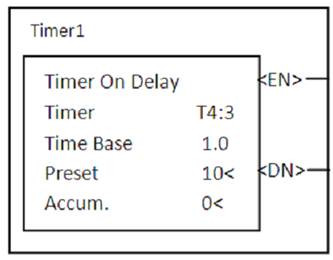

Timer

This is also

called as «TON». Figure 7.4.3 shows the

schematic of a Timer. It is used to turn an output ON or OFF after the timer

has been ON for preset time interval. This output instruction begins timing when

rung goes true. It waits the specified amount of time (As specified in Preset),

keeps track of accumulated intervals which have occurred (ACCUM), and sets DN

(Done) bit when ACCUM time equals preset time.

As long as rung

condition remains true, Timer adjusts its accumulated value to each evaluation

until it reaches the preset value. The accumulated value is reset when rung

condition go false, regardless of whether timer has timed out. «TIME BASE» is an amount of time

after which accumulator increases its value by 1.

Fig. 7.4.3. Schematic

of a Timer

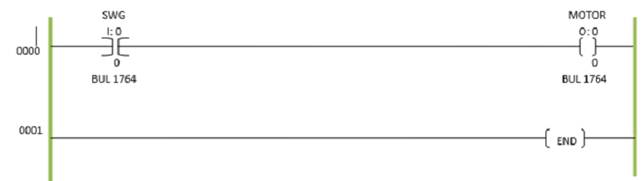

7.5. TO RUN THE CONVEYER BELT WITH THE HELP OF SWITCHES

As discussed in

earlier sections, PLCs are controlled through Ladder Logic. In input section of

the ladder, name of the input device must be mentioned on the top of symbol,

followed by primary input port. Secondary input port is mentioned just below

symbol. In similar way, output symbol should be mentioned with name and output

ports as shown in figure 7.5.1.

Fig. 7.5.1. A

rung to run the conveyor belt

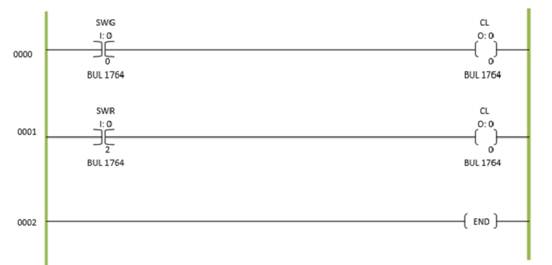

To control

movement of pneumatic devices in an industry with PLCs. Figure 7.5.2. shows a

program code to control the motion of pneumatic cylinder with a switch.

Fig. 7.5.2. Program

code to actaute a pneumatic cylinder

In industrial

applications, it is required to use various sensors to control the operations

of systems and proceses using PLCs. Figure 7.5.2 shows a typical program to

operate an electric motor and a pnematic cylinder with the help of some sensors

such pneumatic proximity switch. To control a mechatronics system we need to

combine various mechanical and electrical input and output devices and to

operate them in a sequential manner. Consider a prototype of

industrial assembly line with 3 stations as shown in Figure 7.4.2.

At first station

ST1, the sensor identifies an object (finished product) on the conveyer belt

and sends a signal to the controller. Controller processes this information and

actuates the electric motor to run the conveyer belt.

Second Station

ST2: It is allotted for the inspection of the finished product or object. At

ST2, conveyer belt stops. In case any fault diagnosed by the inspection system,

the product will be taken away by the pneumatic actuators placed at Station 3,

ST3.