LECTURE ¹10

DRIVES AND MECHANISMS. LINEAR

MOTION DRIVES

10.1. MECHANICAL ACTUATORS

Linear motion drives are

mechanical transmission systems which are used to convert rotary motion into

linear motion. The conventional thread forms like vee or square are not

suitable in CNC because of their high wear and less efficiency. Therefore CNC

machines generally employ ball screw for driving their workpiece carriages.

These drives provide backlash free operation with low friction-wear

characteristics. These are efficient and accurate in comparison with that of

nut-and-screw drives. Most widely used linear motion drives are ball screws.A

linear actuator is an actuator that produces motion in a straight line. Linear

actuators are extensively required in machine tools and industrial machinery.

Hydraulic or pneumatic cylinders inherently produce linear motion. Many other

mechanisms are used to generate linear motion from a rotating motor.

Mechanical

actuators

These actuators convert

rotary motion into linear motion. Conversion is made by using various types of

mechanisms such as:

·

screw: this is a

simple machine known as screw. by rotating the screw shaft, the actuator's nut

moves in a line;

·

wheel and axle:

hoist, winch, rack and pinion, chain drive, belt drive, rigid chain and rigid

belt actuators operate on the principle of the wheel and axle. a rotating wheel

moves a cable, rack, chain or belt to produce linear motion;

·

cam: discussed

in last lecture;

·

hydraulic

actuators utilize pressurized fluid to produce a linear motion where as

pneumatic systems employ compressed air for the same purpose. we will be

discussing about these systems in lecture 4 and 5.

Piezoelectric

actuators

These actuators work on the

principle of Piezoelectricity which states that application of a voltage to a

crystal material such as Quartz causes it to expand. However, very high

voltages produce only tiny expansions. As a result, though the piezoelectric

actuators achieve extremely fine positioning resolution, but also have a very short

range of motion. In addition, piezoelectric materials exhibit hysteresis which

makes it difficult to control their expansion in a repeatable manner.

Electro-mechanical

actuators

Electro-mechanical actuators

are similar to mechanical actuators except that the control knob or handle is

replaced with an electric motor. Rotary motion of the motor is converted to

linear displacement. In this type of actuators, an electric motor is

mechanically connected to rotate a lead screw. A lead screw has a continuous

helical thread machined on its circumference running along the length (similar

to the thread on a bolt). Threaded onto the lead screw is a lead nut or ball

nut with corresponding helical threads. The nut is prevented from rotating with

the lead screw (typically the nut interlocks with a non-rotating part of the

actuator body). Therefore, when the lead screw is rotated, the nut will be

driven along the threads. The direction of motion of the nut depends on the

direction of rotation of the lead screw. By connecting linkages to the nut, the

motion can be converted to usable linear displacement.

There are many types of

motors that can be used in a linear actuator system. These include dc brush, dc

brushless, stepper, or in some cases, even induction motors. Electromechanical

linear actuators find applications in robotics, optical and laser equipments,

or X-Y tables with fine resolution in microns.

Linear motors

The working principle of a

linear motor is similar to that of a rotary electric motor. It has a rotor and

the stator circular magnetic field components are laid down in a straight line.

Since the motor moves in a linear fashion, no lead screw is needed to convert

rotary motion into linear. Linear motors can be used in outdoor or dirty

environments; however the electromagnetic drive should be waterproofed and

sealed against moisture and corrosion.

10.2. BALL-SCREW BASED LINEAR DRIVES

Ball screw is also called as

ball bearing screw or recirculating ball-screw. It consists of a screw spindle,

a nut, balls and integrated ball return mechanism a shown in Figure 10.2.1.

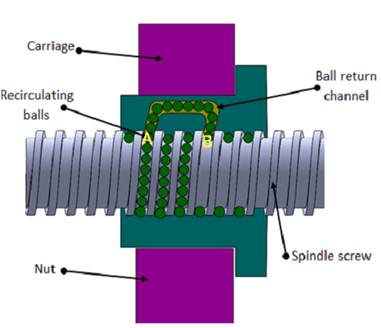

Fig. 10.2.1. Ball-screw

configuration

The flanged nut is attached

to the moving part of CNC machine tool. As the screw rotates, the nut

translates the moving part along the guide ways. However, since the groove in

the ball screw is helical, its steel balls roll along the helical groove, and,

then, they may go out of the ball nut unless they are arrested at a certain

spot.

Thus, it is necessary to

change their path after they have reached a certain spot by guiding them, one after

another, back to their «starting point» (formation of a recirculation path). The

recirculation parts play that role. When the screw shaft is rotating, as shown

in Figure 10.2.1., a steel ball

at point (A) travels 3 turns of screw groove, rolling along the grooves of the

screw shaft and the ball nut, and eventually reaches point (B). Then, the ball

is forced to change its pathway at the tip of the tube, passing back through

the tube, until it finally returns to point (A). Whenever the nut strokes on

the screw shaft, the balls repeat the same recirculation inside the return

tube.

When debris or foreign

matter enter the inside of the nut, it could affect smoothness in operation or

cause premature wearing, either of which could adversely affect the ball

screw’s functions. To prevent such things from occurring, seals are provided to

keep contaminants out. There are various types of seals viz. plastic seal or

brush type of seal used in ball-screw drives.

Characteristics

of ball screws

High mechanical efficiency

In ball screws, about 90% or

more of the force used to rotate the screw shaft can be converted to the force

to move the ball nut. Since friction loss is extremely low, the amount of force

used to rotate the screw shaft is as low as one third of that needed for the

acme thread lead screw.

Low in wear

Because of rolling contact,

wear is less than that of sliding contact. Thus, the accuracy is high. Ball

screws move smoothly enough under very slow speed. They run smoothly even under

a load.

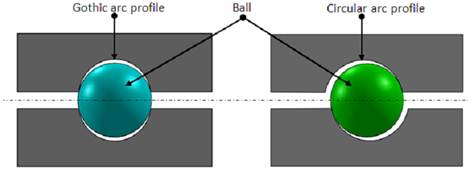

Thread Form

The thread form used in

these screws can either be gothic arc type (Fig. 10.2.2 a) or circular arc type (Fig. 10.2.2 b). The friction in this kind of arrangement is of

rolling type. This reduces its wear as comparison with conventional sliding

friction screws drives.

Fig. 10.2.2. Thread forms (a) Gothic arc (b) Circular arc

Recirculating ball screws

are of two types. In one arrangement the balls are returned using an external

tube. In the other arrangement the balls are returned to the start of the

thread in the nut through a channel inside the nut.

Preloading

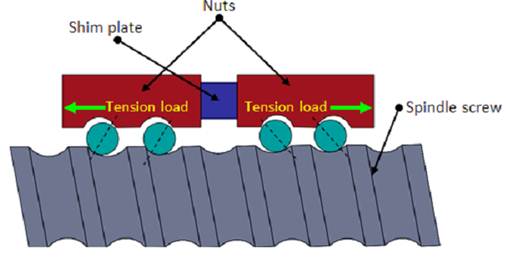

Fig. 10.2.3. Double nut

preloading system

In order to obtain

bidirectional motion of the carriage without any positional error, the backlash

between the nut and screw should be minimum. Zero backlash can be obtained by

fitting two nuts with preloading (tension or compression) or by applying a load

which exceeds the maximum operating load. Figure 4.4.3 shows double nut

preloading system. A shim plate (spacer) is inserted between two nuts for

preloading. Preload is to create elastic deformations (deflections) in steel

balls and ball grooves in the nut and the screw shaft in advance by providing

an axial load. As a result the balls in one of the nuts contact the one side of

the thread and balls in the other nut contact the opposite side.

Effects of

preload

Effects of preload:

·

zero backlash:

it eliminates axial play between a screw shaft and a ball nut;

·

it minimizes

elastic deformation caused by external force, thus the rigidity enhances.

In case mounting errors,

misalignment between the screw shaft and the nut may occur this further

generates distortion forces. This could lead to the problems such as:

·

shortened

service life;

·

adverse effect

on smooth operation;

·

reduced

positioning accuracy;

·

generation of

noise or vibration;

·

breakage of

screw shaft.

Advantages of ball screws:

·

highly efficient

and reliable;

·

less starting

torque;

·

lower co

efficient of friction compared to sliding type screws and run at cooler temperatures;

·

power

transmission efficiency is very high and is of the order of 95 %;

·

could be easily preloaded

to eliminate backlash;

·

the friction

force is virtually independent of the travel velocity and the friction at rest

is very small; consequently, the stick-slip phenomenon is practically absent, ensuring uniformity

of motion;

·

has longer

thread life hence need to be replaced less frequently;

·

ball screws are

well -suited to high through output, high speed applications or those with

continuous or long cycle times;

·

smooth movement

over full range of travel.

Disadvantages of ball screws:

Ø tend to vibrate;

Ø

require periodic

overhauling to maintain their efficiency;

Ø

inclusion of

dirt or foreign particles reduces the life of the screws;

Ø

not as stiff as

other power screws, thus deflection and critical speed can cause difficulties;

Ø

they are not

self-locking screws hence cannot be used in holding devices such as vices;

Ø

require high

levels of lubrication.

Applications of ball screws:

o ball screws are employed in cutting machines, such as

machining center and nc lathe where accurate positioning of the table is

desired;

o used in the equipments such as lithographic equipment

or inspection apparatus where precise positioning is vital;

o high precision ball screws are used in steppers for

semiconductor manufacturing industries for precision assembly of micro parts;

o used in robotics application where precision

positioning is needed;

o

used in medical

examination equipments since they are highly accurate and provide smooth motion.

10.3. INDEXING MECHANISMS

Mechanism is a system of

rigid elements arranged and connected to transmit motion in a predetermined

fashion. Indexing mechanisms generally converts a rotating or oscillatory

motion to a series of step movements of the output link or shaft. In machine

tools the cutting tool has to be indexed in the tool turret after each

operation. Also in production machines the product has to be indexed from

station to station and need to be stopped if any operation is being performed

in the station. Such motions can be accomplished by indexing mechanisms.

Indexing mechanisms are also useful for machine tool feeds. There are several

methods used to index but important types are ratchet and pawl, rack and

pinion, Geneva mechanism and cam drive.

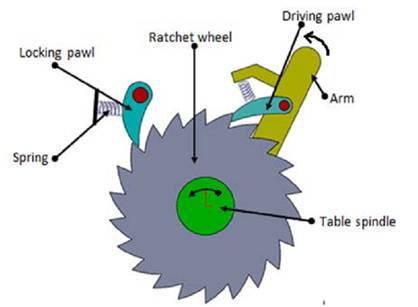

Ratchet and pawl

mechanism

Fig. 10.3.1. Ratchet and pawl mechanism

A ratchet is a device that

allows linear or rotary motion in only one direction. Figure 10.3.1 shows a

schematic of the same. It is used in rotary machines to index air operated

indexing tables. Ratchets consist of a gearwheel and a pivoting spring loaded

pawl that engages the teeth. The teeth or the pawl, are at an angle so that

when the teeth are moving in one direction the pawl slides in between the

teeth. The spring forces the pawl back into the depression between the next

teeth. The ratchet and pawl are not mechanically interlocked hence easy to set up. The table may over

travel if the table is heavy when they are disengaged. Maintenance of this

system is easy.

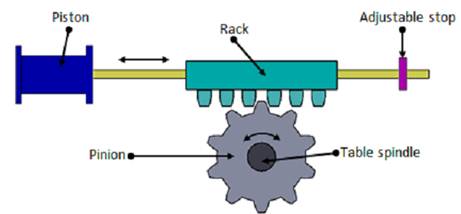

Rack and pinion

mechanism

Fig. 10.3.2. Rack and pinion

mechanism

A rack and pinion gear

arrangement usually converts rotary motion from a pinion to linear motion of a

rack. But in indexing mechanism the reverse case holds true. The device uses a

piston to drive the rack, which causes the pinion gear and attached indexing

table to rotate (Fig. 10.3.2). A clutch is used to provide rotation in the

desired direction. This mechanism is simple but is not considered suitable for

high-speed operation.

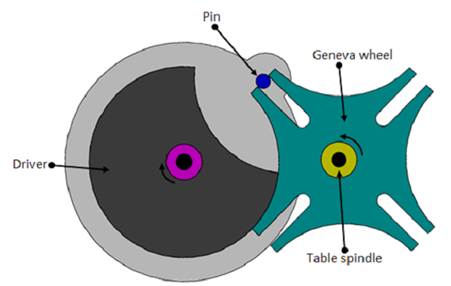

Geneva mechanism

The Geneva drive is also

commonly called a Maltese cross mechanism. The Geneva mechanism translates a

continuous rotation into an intermittent rotary motion. The rotating drive

wheel has a pin that reaches into a slot of the driven wheel. The drive wheel

also has a raised circular blocking disc that locks the driven wheel in

position between steps (Fig. 10.3.3). There are three basic types of Geneva motion

mechanisms namely external, internal and spherical. The spherical Geneva

mechanism is very rarely used. In the simplest form, the driven wheel has four

slots and hence for each rotation of the drive wheel it advances by one step of

90°.

Fig. 10.3.3. Geneva mechanism

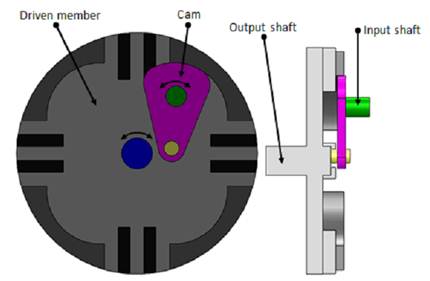

If the driven wheel has n

slots, it advances by 360°/n per full rotation of the drive wheel. In an

internal Geneva drive the axis of the drive wheel of the internal drive is supported

on only one side (Fig. 10.3.4). The angle by which the drive wheel has to

rotate to effect one step rotation of the driven wheel is always smaller than

180° in an external Geneva drive and is always greater than 180° in an internal

one. The external form is the more common, as it can be built smaller and can

withstand higher mechanical stresses.

Fig. 10.3.4. Internal Geneva

mechanism

Because the driven wheel

always under full control of the driver, impact is a problem. It can be reduced

by designing the pin in such a way that the pin picks up the driven member as slowly

as possible. Both the Geneva mechanisms can be used for light and heavy duty

applications. Generally, they are used in assembly machines.

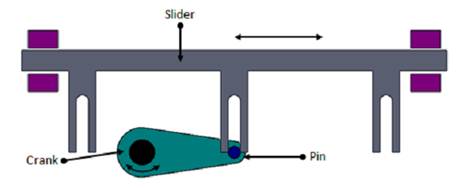

Intermittent linear motion

from rotary motion can also be obtained using Geneva mechanism (Fig. 10.3.5).

This type of movement is basically required in packaging, assembly operations,

stamping, embossing operations in manufacturing automation.

Fig. 10.3.5. Linear

intermittent motion using Geneva mechanism

10.4. MOTION PICTURE PROJECTORS

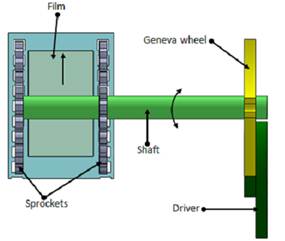

Geneva drive mechanism is

used in conventional-mechanical type movie projectors. Figure 10.4.1 shows the schematic of movie projector with Geneva

mechanism. The film does not run continuously through the projector. It is

requited that the film should advance frame by frame and stands still in front

of the lens for fraction of a second. Modern film projectors use an

electronically controlled indexing mechanism which allows the fast-forwarding

of the film.

Fig. 10.4.1. Motion picture

projector with Geneva mechanism

Machining centers are used

to carry out multiple operations like drilling, milling, boring etc. in one set

up on multiple faces of the workpiece. These operations require a number of

different tools. Tool changing operation is time consuming which reduces the

machine utilization. Hence the tools should be automatically changed to reduce

the idle time. This can be achieved by using automatic tool changer (ATC)

facility. It helps the workpiece to be machined in one setup which increases

the machine utilization and productivity. Large numbers of tools can be stored

in tool magazines. Tool magazines are specified by their storage capacity, tool

change procedure and shape. The storage capacity ranges from 12 to 200. Some of

the magazines are discuseed as follows.

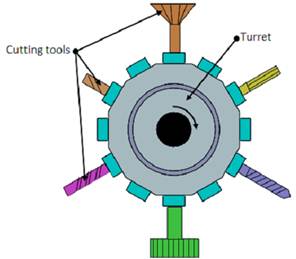

Tool turret

It is the simplest form of

tool magazine. Figure 10.4.2 the schematic

of a turret with a capacity to hold twelve tools. It consists of a tool storage

without any tool changer.

Fig. 10.4.2. Tool turret

The turret is indexed in the

required position for desired machining operation. Advantage of the turret is

that the tool can easily be identified, but the time consumed for tool change

is more unless the tool is in the adjecent slot.

Tool magazines are generally

employed in CNC drilling and milling machines. Compared to tool turrets the

tool magazines can hold more number of tools therefore proper management of

tools is essential. Duplication of the tools is possible and a new tool of same

type may be selected when a particular tool is worn off. The power required to

move the tools in a tool magazine is more in comparison with that required in

tool turrets. The following are some of the tool magazines used in automation:

o disc or drum type;

o chain type;

o disk or drum type.

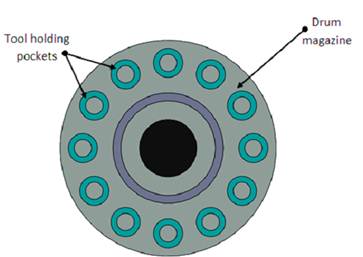

Disc type

magazine

The disc type tool magazine

rotates to get the desired tool in position with the tool change arm (Fig.

10.4.3). Larger the diameter of the disc/drum more the number of tools it can

hold. It has pockets where tool can be inserted. In case of drum type magazine

which can store large amount of tools, the pockets are on the surface along the

length. It carries about 12 to 50 tools. If the number of tools are less the

disc is mounted on top of the spindle to minimize the travel of tool between

the spindle and the disc. If the tools are more then, the disc is wall mounted

or mounted on the machining center column. If the disc is column mounted then,

it needs an additional linear motion to move it to the loading station for tool

change.

Fig. 10.4.3. Drum magazine

The tool change activity

requires the following motions:

a)

the spindle

stops at the correct orientation for the tool change arm to pick the tool from

the spindle;

b)

tool change arm

moves to the spindle;

c)

tool change arm picks

the tool from the spindle;

d)

tool change arm

indexes to reach the tool magazine;

e)

tool magazine

indexes so that the tool from the spindle can be placed;

f)

the tool is

placed in the tool magazine;

g)

the tool

magazine indexes to bring the required tool to the tool change position;

h)

tool change arm

picks the tool from the tool magazine;

i)

tool change arm

indexes to reach the spindle;

j)

new tool is

placed in the spindle;

k)

tool change arm

moves back to its parking position.

Advantages of automatic tool changer

Advantages of automatic tool changer:

·

increase in

operator safety by changing tools automatically;

·

changes the

tools in seconds for maintenance and repair;

·

increases

flexibility;

·

heavy and large

multi-tools can easily be handled;

·

decreases total

production time;

The parts riding on the

rotating table are positioned at each station for their processing or assembly

operation. This type of equipment is called as an indexing machine or dial

index machine. These are generally used to carry out assembly operations of

small sized products such as watches, jewelery, electronic circuits, small

molds/dies, consumer appliances etc.