LECTURE

5

ROBOT

MECHANISMS

A robot is a machine capable of physical

motion for interacting with the environment. Physical interactions include

manipulation, locomotion, and any other tasks changing the state of the

environment or the state of the robot relative to the environment. A robot has

some form of mechanisms for performing a class of tasks. A rich variety of

robot mechanisms has been developed in the last few decades. In this chapter,

we will first overview various types of mechanisms used for generating robotic

motion, and introduce some taxonomy of mechanical structures before going into

a more detailed analysis in the subsequent chapters.

Joint Primitives and Serial Linkages

A robot mechanism is a multi-body system

with the multiple bodies connected together. We begin by treating each body as

rigid, ignoring elasticity and any deformations caused by large load

conditions. Each rigid body involved in a robot mechanism is called a link, and

a combination of links is referred to as a linkage. In describing a linkage it

is fundamental to represent how a pair of links is connected to each other.

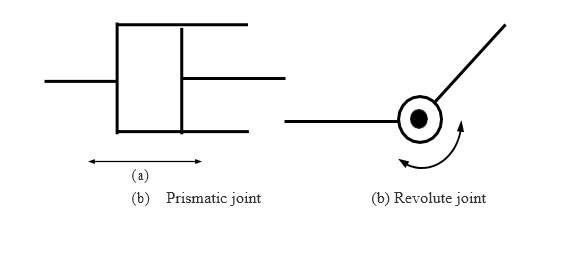

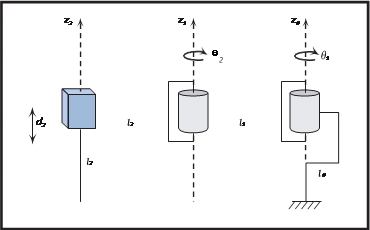

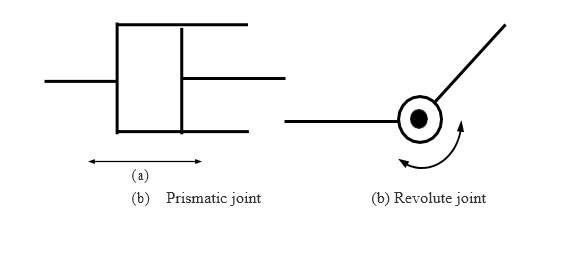

There are two types of primitive connections between a pair of links, as shown in

Figure 5. 1. The first is a prismatic joint where the pair of links makes a

translational displacement along a fixed axis. In other words, one link slides

on the other along a straight line. Therefore, it is also called a sliding

joint. The second type of primitive joint is a revolute joint where a pair of

links rotates about a fixed axis. This type of joint is often referred to as a

hinge, articulated, or rotational joint.1

Figure 5. 1 Primitive joint types: (a) a prismatic joint and (b)

a revolute joint

Combining these two types of primitive

joints, we can create many useful mechanisms for robot manipulation and

locomotion. These two types of primitive joints are simple to build and are

well grounded in engineering design. Most of the robots that have been built

are combinations of only these two types. Let us look at some examples.

Robot mechanisms analogous

to coordinate systems

One of the fundamental

functional requirements for a robotic system is to locate its end- effecter,

e.g. a hand, a leg, or any other part of the body performing a task, in

three-dimensional space. If the kinematic structure of such a robot mechanism

is analogous to a coordinate system, it may suffice this positioning

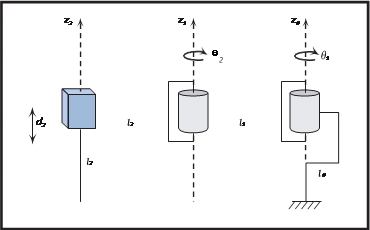

requirement. Figures 5. 2 ~ 4 show three types of robot arm structures

corresponding to the Cartesian coordinate system, the cylindrical coordinate

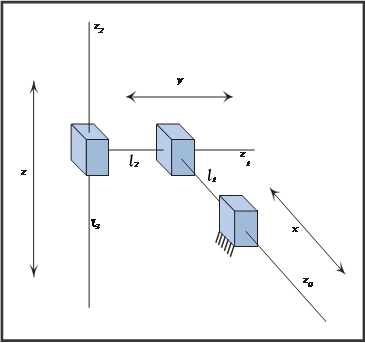

system, and the spherical coordinate system respectively. The Cartesian

coordinate robot shown in Figure 5. 2 has three prismatic joints, corresponding

to three axes denoted x, y , and z. The cylindrical robot consists of one

revolute joint and two prismatic joints, with r, and z representing the coordinates

of the end-effecter. Likewise, the spherical robot has two revolute joints

denoted and one prismatic joint denoted r.

Figure 5. 2

Cartesian coordinate robot

Figure 5. 3

Cylindrical coordinate robot

Figure 5. 4

Spherical coordinate robot.

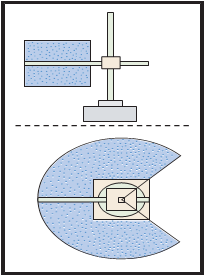

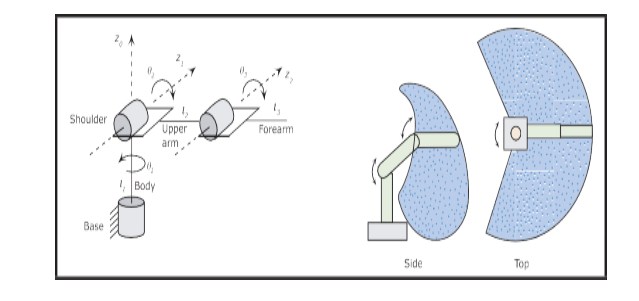

There are many other ways of locating an

end-effecter in three-dimensional space. Figure 5. 5 ~ 7 show three other

kinematic structures that allow the robot to locate its end-effecter in

three-dimensional space. Although these mechanisms have no analogy with common

coordinate systems, they are capable of locating the end-effecter in space, and

have salient features desirable for specific tasks. The first one is a

so-called SCALAR robot consisting of two revolute joints and one prismatic

joint.

This robot structure is

particularly desirable for assembly automation in manufacturing systems, having

a wide workspace in the horizontal direction and an independent vertical axis

appropriate for insertion of parts.

Figure 5. 5 SCALAR

type robot.

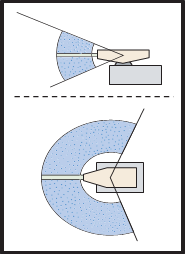

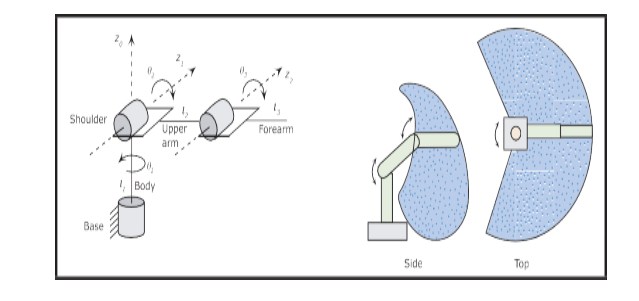

The second type, called an articulated

robot or an elbow robot, consists of all three revolute joints, like a human

arm. This type of robot has a great degree of flexibility and versatility,

being the most standard structure of robot manipulators. The third kinematic

structure, also consisting of three revolute joints, has a unique mass

balancing structure. The counter balance at the elbow eliminates gravity load

for all three joints, thus reducing toque requirements for the actuators. This

structure has been used for the direct-drive robots having no gear reducer.

Figure 5. 6 Articulated robot

Note that all the above robot

structures are made of serial connections of primitive joints. This class of

kinematic structures, termed a serial linkage, constitutes the fundamental

makeup of robot mechanisms. They have no kinematic constraint in each joint

motion, i.e. each joint displacement is a generalized coordinate. This

facilitates the analysis and control of the robot mechanism. There are,

however, different classes of mechanisms used for robot structures. Although

more complex, they do provide some useful properties. We will look at these

other mechanisms in the subsequent sections.

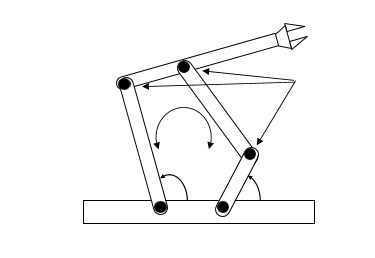

Parallel Linkages

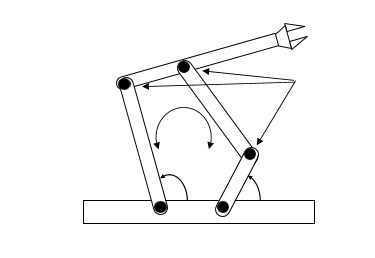

Primitive joints can be arranged in

parallel as well as in series. Figure 5.7 illustrates such a parallel link

mechanism. It is a five-bar-linkage consisting of five links, including the base

link, connected by five joints. This can be viewed as two serial linkage arms

connected at a particular point, point A in the figure. It is important to note

that there is a closed kinematic chain formed by the five links and, thereby,

the two serial link arms must conform to a certain geometric constraint. It is

clear from the figure that the end-effecter position is determined if two of

the five joint angles are given. For example, if angles 1? and 3? of joints 1

and 3 are determined, then all the link positions are determined, as is the

end-effecter’s. Driving joints 1 and 3 with two actuators, we can move the

end-effecter within the vertical plane. It should be noted that, if more than

two joints were actively driven by independent actuators, a conflict among

three actuators would occur due to the closed-loop kinematic chain. Three of

the five joints should be passive joints, which are free to

rotate. Only two joints should be active joints, driven by independent

actuators.

Figure 5.7 Five-bar-link parallel link robot

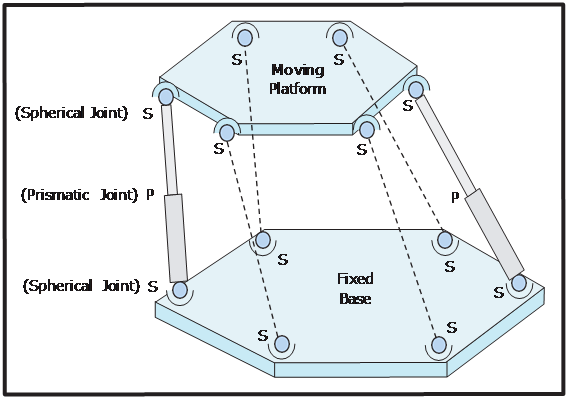

Figure 5. 8 shows the Stewart mechanism, which consists of a

moving platform, a fixed base, and six powered cylinders connecting the moving

platform to the base frame. The position and orientation of the moving platform

are determined by the six independent actuators. The load acting on the moving

platform is born by the six "arms". Therefore, the load capacity is

generally large, and dynamic response is fast for this type of robot mechanisms.

Note, however, that this mechanism has spherical joints, a different type of

joints than the primitive joints we considered initially.

Figure 5. 8 Stewart mechanism parallel-link robot