LECTURE

4

PNEUMATIC

SYSTEM

Pneumatic technology

deals with the study of

behavior and applications of compressed air in our daily

life in general

and manufacturing automation in particular.

Pneumatic systems use air as

the medium which is abundantly

available and can be exhausted

into the atmosphere after completion of the

assigned task.

1.

Basic Components of Pneumatic

System:

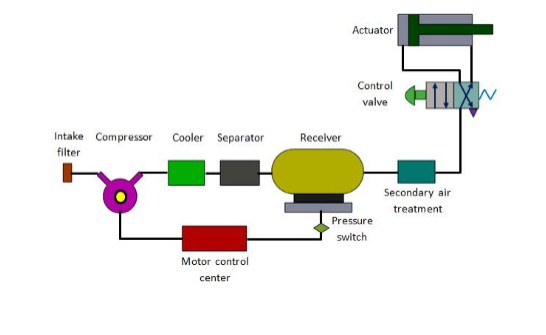

Fig. 4. 1 Components of a pneumatic system

Important components of a pneumatic system are shown in

fig.4.1.

Х

Air filters: These are used

to filter out the contaminants

from the air.

Х

Compressor: Compressed air is generated

by using air compressors. Air compressors are either diesel or

electrically operated. Based on the

requirement of compressed air, suitable capacity compressors may be used.

Х

Air cooler: During compression operation, air temperature increases. Therefore coolers are used

to reduce the temperature of the compressed

air.

Х

Dryer: The water vapor or

moisture in the air is

separated from the air by using a dryer.

Х

Control Valves: Control valves are

used to regulate,

control and monitor for control of direction flow, pressure etc.

Х

Air Actuator: Air cylinders and motors are

used to obtain

the required movements of mechanical elements

of pneumatic system.

Х

Electric Motor: Transforms electrical

energy into mechanical energy. It is used to drive the compressor.

Х

Receiver tank: The compressed air coming from the

compressor is stored in the air receiver.

These components of the pneumatic

system are explained in detail

on the next

pages.

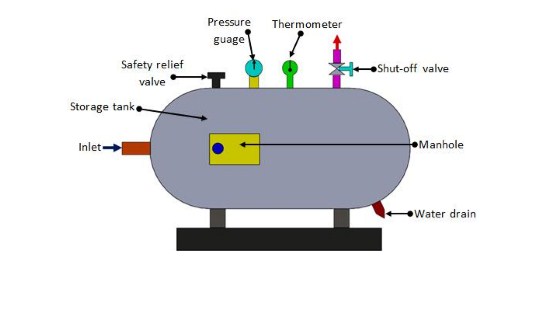

2. Receiver tank

The air is

compressed slowly in the compressor.

But since the pneumatic system

needs continuous supply of air,

this compressed air has to

be stored. The compressed air is stored

in an air

receiver as shown in Figure

4. 2. The air receiver smoothens the pulsating flow

from the compressor. It also helps the

air to cool

and condense the moisture present.

The air receiver

should be large enough to

hold all the air delivered

by the compressor.

The pressure in the receiver

is held higher

than the system operating pressure to compensate

pressure loss in the pipes.

Also the large surface area

of the receiver

helps in dissipating the heat from the

compressed air. Generally the size

of receiver depends on,

ü Delivery

volume of compressor.

ü Air

consumption.

ü Pipeline

network

ü Type and

nature of on-off regulation

ü Permissible

pressure difference in the pipelines

Fig.4.2 Air receiver

3. Compressor:

It is a mechanical device which converts mechanical energy into fluid energy.

The compressor increases the air

pressure by reducing its volume

which also increases the temperature

of the compressed

air. The compressor is selected

based on the pressure it

needs to operate and the

delivery volume.

The compressor

can be classified

into two main types

Х

Positive displacement

compressors and

Х

Dynamic displacement

compressor

Positive displacement compressors include piston type, vane

type, diaphragm type and screw

type.

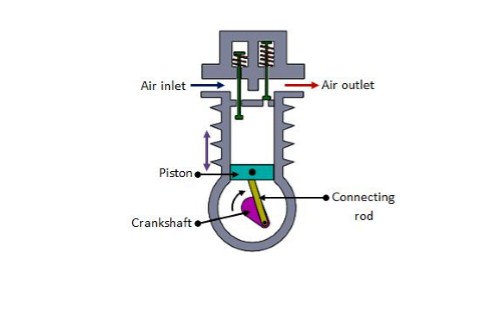

3.1 Piston compressors

Fig. 4.3 Single acting piston

compressor

Piston compressors are commonly used

in pneumatic systems. The simplest

form is single

cylinder compressor (Fig. 4.3). It produces

one pulse of air per

piston stroke. As the piston

moves down during the inlet

stroke the inlet valve opens

and air is

drawn into the cylinder. As

the piston moves up the

inlet valve closes and the

exhaust valve opens which allows

the air to

be expelled. The valves are

spring loaded. The single cylinder

compressor gives significant amount of pressure pulses

at the outlet

port. The pressure developed is about 3-40 bar.

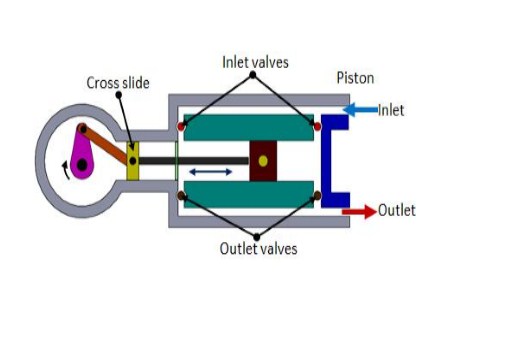

3.2 Double acting

compressor

Fig. 4.4 Double acting piston

compressor

The pulsation of air

can be reduced

by using double acting compressor

as shown in Figure 4.4. It has two

sets of valves

and a crosshead. As the piston

moves, the air is compressed

on one side

whilst on the other side

of the piston,

the air is

sucked in. Due to the

reciprocating action of the piston,

the air is

compressed and delivered twice in one piston

stroke. Pressure higher than 30bar can be produced.

3.3 Multistage compressor

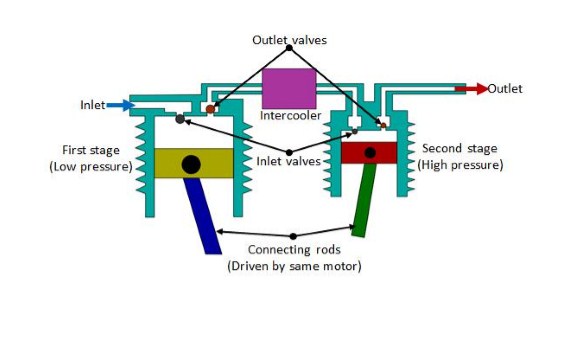

Fig. 4.5 Multi-stage compressor

As the pressure of

the air increases,

its temperature rises. It is

essential to reduce the air

temperature to avoid damage of

compressor and other mechanical elements. The multistage

compressor with intercooler in-between is shown in

Figure 4.5. It is used to

reduce the temperature of compressed air during the compression

stages. The inter-cooling reduces the volume of

air which used to increase

due to heat.

The compressed air from the

first stage enters the intercooler

where it is cooled. This

air is given

as input to the second

stage where it is compressed

again. The multistage compressor can develop a pressure

of around 50bar.

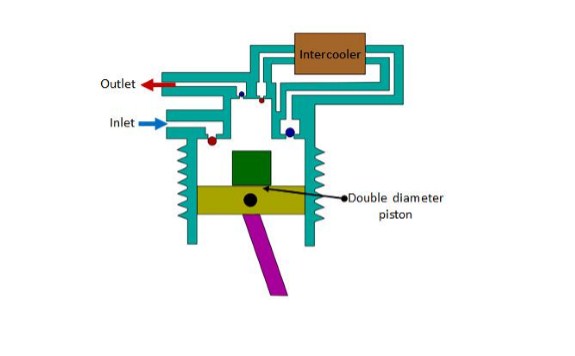

3.4 Combined two

stage compressors

Fig. 4.6 Combined to stage

compressor

In this type,

two-stage compression is carried out

by using the same piston

(Fig. 4.6). Initially when the piston

moves down, air is sucked

in through the inlet valve.

During the compression process, the air moves

out of the

exhaust valve into the intercooler.

As the piston

moves further the stepped head

provided on the piston moves

into the cavity thus causing

the compression of air. Then,

this is let

out by the

exhaust port.