LECTURE 2

PRESSURE RELIEF VALVES

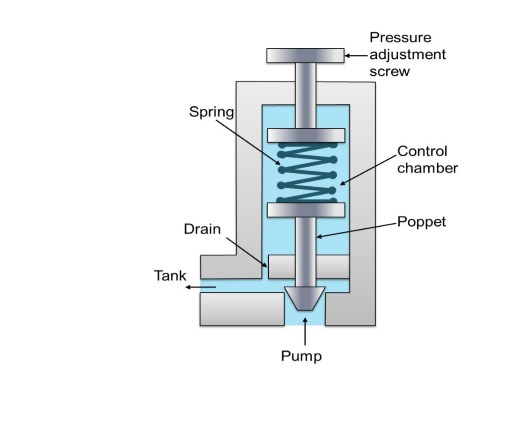

The pressure relief valves are used to protect the hydraulic components from excessive

pressure. This is one of the most important components of a hydraulic system

and is essentially required for safe operation of the system. Its primary

function is to limit the system pressure within a specified range. It is

normally a closed type and it opens when the pressure exceeds a specified

maximum value by diverting pump flow back to the tank. The simplest type valve

contains a poppet held in a seat against the spring force as shown in Figure 2.1. The fluid enters from the opposite

side of the poppet. When the system pressure exceeds the preset value, the

poppet lifts and the fluid is escaped through the orifice

to the storage tank directly. It reduces the system pressure and as the

pressure reduces to the set limit again the valve

closes. This valve does not provide a flat cut-off pressure limit with flow

rate because the spring must be deflected more when the

flow rate is higher. Various types of pressure control valves are discussed in the following sections:

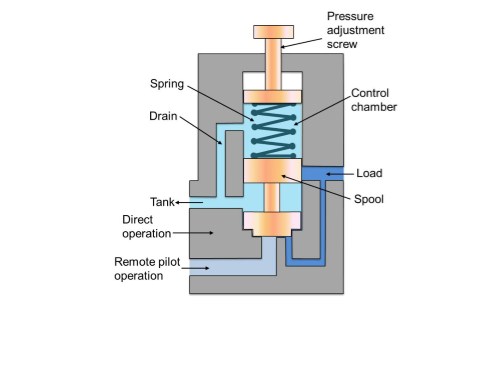

1. Direct type of relief valve

Figure 2. 1

Pressure Relief Valve

Schematic of direct pressure

relief valve is shown in figure 2.1. This

type of valves has two ports; one of which is connected

to the pump and another is connected to the tank. It consists of a spring

chamber where poppet is placed with a spring force.

Generally, the spring is adjustable to set the maximum pressure limit of the

system. The poppet is held in position by combined

effect of spring force and dead weight of spool. As the pressure exceeds this

combined force, the poppet raises and excess fluid bypassed to the reservoir

(tank). The poppet again reseats as the pressure drops below the pre-set value.

A drain is also provided in the control chamber. It

sends the fluid collected due to small leakage to the tank and thereby prevents

the failure of the valve.

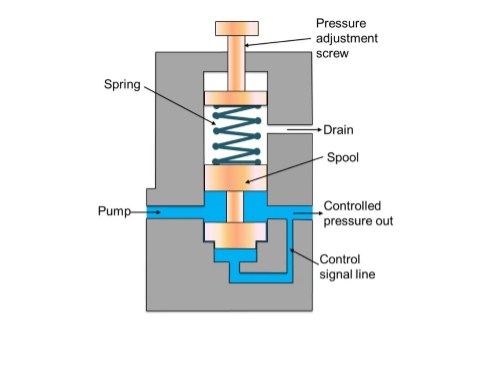

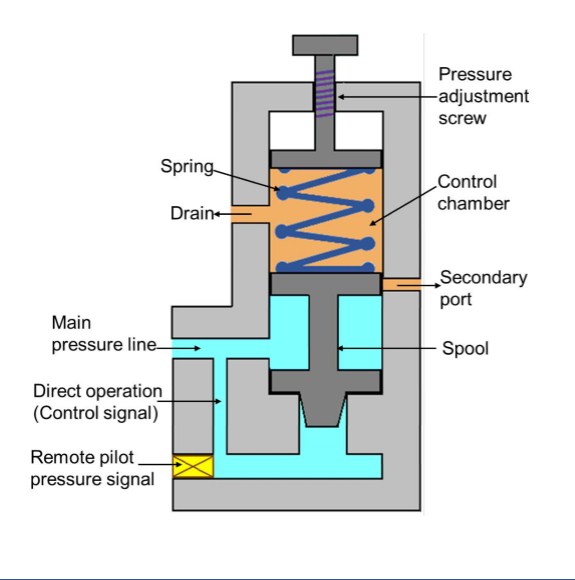

2. Unloading Valve

Figure 2. 2 Unloading

Valve

The construction of unloading valve is shown in Figure 2.2. This valve consists of a control chamber with an adjustable spring which pushes the spool down. The valve has two ports:

one is connected to the tank and another is connected

to the pump. The valve is operated by movement of the spool.

Normally, the valve is closed and the tank port is also

closed. These valves are used to permit a pump to

operate at the minimum load. It works on the same principle as direct control

valve that the pump delivery is diverted to the tank

when sufficient pilot pressure is applied to move the spool. The pilot pressure

maintains a static pressure to hold the valve opened. The pilot pressure holds

the valve until the pump delivery is needed in the

system. As the pressure is needed in the hydraulic

circuit; the pilot pressure is relaxed and the spool moves down due to the

self-weight and the spring force. Now, the flow is diverted

to the hydraulic circuit. The drain is provided to

remove the leaked oil collected in the control chamber to prevent the valve

failure. The unloading valve reduces the heat buildup due to fluid discharge at

a preset pressure value.

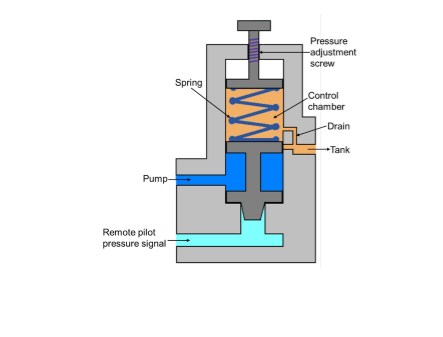

3. Sequence valve

Figure 2. 3 Sequence valve