Topic 6.1 Machining accuracy

6.1.1 Standardization of permissible

deviations of sizes, forms

and placement of surfaces

One of the important

indicators of the quality of the machine, which significantly affects all

criteria of its efficiency and reliability, as well as operational parameters,

is the accuracy of manufacturing and assembly of conjugated elements. The

principle of designing and manufacturing parts, which ensures the possibility

of correct assembly or replacement during repairs of independently manufactured

parts and assembly units without additional processing and fitting them while

maintaining the appropriate quality and reliability of the connection, is

called interchangeability, which is

a characteristic feature of modern mechanical engineering.

A distinction is made

between complete and incomplete interchangeability. Complete - provides for the correct connection of all conjugated

parts entering assembly operations. They are provided with high precision in

the manufacture of parts. In the case of incomplete

interchangeability, the correct connection of only part of the parts

manufactured with lower accuracy is achieved. In these cases, group selection

of parts is used for assembly (selective assembly) or various compensators and

other additional technological means are used.

The

interchangeability of machine parts is ensured by the system of tolerances and

fits. The general provisions and foundations of the construction of this system

for smooth machine elements (cylindrical or limited by parallel planes) with

nominal dimensions up to 3150 mm are established by standards. In accordance

with these standards, we will consider some terminology related to the concepts

of dimensions, deviations, tolerances, and qualities.

Size – numerical value of a linear real value (diameter, length, etc.) in

the selected units. In mechanical engineering, dimensions are given in

millimeters. There are actual, marginal and nominal sizes.

Effective size - the size of the element, which is established

by measurement.

Boundary dimensions

are two maximum allowable dimensions of an element, between which the actual

size must be. The largest (smallest) limit size is the largest (smallest)

allowable element size.

The nominal size is the size relative to

which deviations are determined. The nominal dimensions are selected during the

design process based on strength calculations or on the basis of constructive

considerations and are placed on the drawing of the parts or the connection of

parts.

Deviation is the algebraic difference between the real (or

limit) and the corresponding nominal dimensions.

Limit deviation is the algebraic difference between the

limit and the corresponding nominal dimensions. Distinguish between upper and

lower deviation. The upper (lower) deviation is the algebraic difference

between the largest (smallest) limit and the corresponding nominal dimensions.

The zero line is a line corresponding to

the nominal size, from which size deviations are set aside in the graphic

representation of the fields of tolerances and landings. In the case of

horizontal placement, its positive deviations are placed upwards from it, and

negative deviations are placed downwards.

Tolerance is the difference between the largest and smallest

limit dimensions or the algebraic difference between the upper and lower

deviations. The tolerance field is a field limited by the largest and smallest

limit sizes and is determined by the tolerance and its position relative to the

nominal size.

Tolerance fields for

conjugated elements are set differently for three ranges of changes in nominal

sizes: small - up to 1 mm, medium - 1...500 mm and large - 500...3150 mm. In

mechanical engineering, the average range of nominal sizes is the most widely

used.

The main deviation is one of the two limit

deviations (upper or lower), which determines the position of the tolerance

field relative to the zero line. In the standard tolerance system, there is a

deviation closer to the zero line.

To meet the

requirements for various parts and their fits with certain nominal dimensions,

the standard provides a range of tolerances and basic deviations that

characterize the position of these tolerances relative to the zero line. The

location of the tolerance field in relation to the zero line, which depends on

the nominal size, is indicated by a letter (sometimes two) of the Latin

alphabet, while for holes - a large letter, and for shafts - a small letter.

The greater the size

tolerance, the lower the requirements for the accuracy of the part, the simpler

and cheaper its manufacture. But large parts are more difficult to manufacture

compared to smaller ones with the same deviations from the nominal dimensions.

Therefore, the tolerance is determined by the dimensions of the part. In

addition, the part can be made more precisely (with a smaller tolerance field)

and less precisely (with a larger tolerance field).

To assess the degree

of accuracy, qualities are used -

this is a set of tolerances that corresponds to one level of accuracy for all

nominal sizes. The standard provides for 20 qualities. In order of decreasing

accuracy, qualities are marked as follows: 01,0,1,2,3...18. Qualities

01,0,1,2,3 and 4 are intended for final measures of length, gauges, etc.; in

qualities 5...13, tolerances are given for the dimensions of the mating

surfaces of parts; in qualities 14...18 - for sizes of non-conjugated surfaces.

Since the tolerance

field is determined by the quality, and its position relative to the zero line

is indicated by a letter, the limit deviations of linear dimensions can be

indicated on the drawing of the part by conventional designations of the

tolerance fields. At the same time, the number indicating the size is followed

by the conventional designation of the tolerance field from letters and

numbers, for example, 20H7 or 42с8.

The tolerance field

and limit deviations are given in the tables of the standard and are sometimes

placed in parentheses after the conventional notation of the tolerance field

20H7 (+0.021), 42с8![]() . Deviations equal to zero are not shown in the marking. Two limit

deviations can be positive (in the case when two limit sizes are larger than

the nominal), negative (two limit sizes are smaller than the nominal) and one

positive and the other negative (one limit size is larger and the other is

smaller than the nominal).

. Deviations equal to zero are not shown in the marking. Two limit

deviations can be positive (in the case when two limit sizes are larger than

the nominal), negative (two limit sizes are smaller than the nominal) and one

positive and the other negative (one limit size is larger and the other is

smaller than the nominal).

The accuracy of the part is understood as

its compliance with the requirements of the drawing: in terms of size,

geometric shape, the correct mutual placement of the surfaces being processed

and the degree of their roughness. Regarding the part, there are three

standards of accuracy: accuracy of linear dimensions; accuracy of form;

accuracy of mutual placement of surfaces.

Allowance for linear

dimensions, deviations in form and mutual placement of surfaces affects the

structure of the technological process, labor intensity and cost of products.

The accuracy of parts manufacturing is characterized by deviations from the

given shape and deviations in the mutual placement of individual surfaces. Such

deviations are limited by the appropriate

tolerances assigned under the specific operating conditions of the coupled

parts.

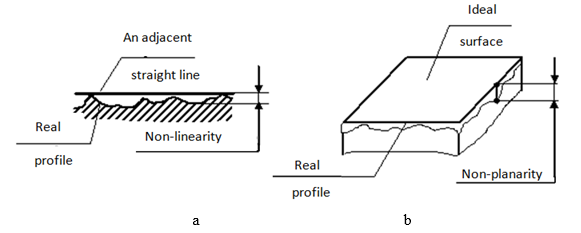

Deviations of the form of conjugated parts

with flat surfaces include non-linearity and non-planarity (Fig. 6.1). Non-linearity is a deviation from a

straight line of the profile of a cross-section of a surface in a plane normal

to it in a given direction. Non-planarity

is a deviation from straightness in any direction along the surface, for

example, convexity, concavity.

Non-planarity surface profile Real Non-linearity

Real straight line An adjacent ![]()

![]()

![]()

![]()

![]()

Fig. 6.1 - Deviation of the

shape of parts with a flat surface

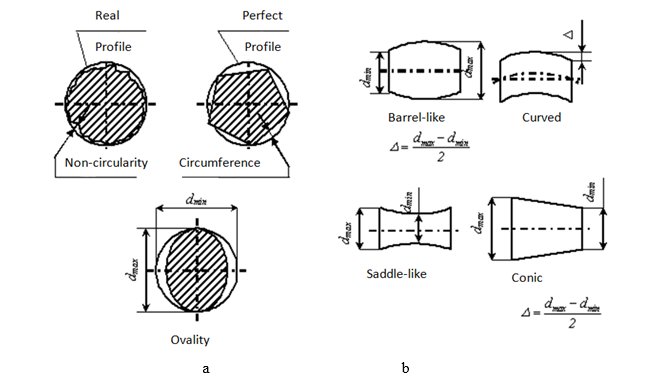

Cylindrical surfaces may have deviations in

shape in transverse and longitudinal sections. Thus, in the cross-section,

deviation of the surface contour from a regular circle is possible -

non-circularity, partial types of which are circumference and ovality (Fig.

6.2, a), which are characterized by the dmax-dmin difference. The following

deviations are possible in the longitudinal section of cylindrical surfaces:

barrel-like, curved, saddle-like and conic (Fig. 6.2, b).

Limit deviations of the shape of

cylindrical surfaces are limited by tolerance fields on the diameter of these

surfaces.

Fig. 6.2 - Deviation

of the shape of parts with cylindrical surfaces:

a – in a cross

section, b – in a longitudinal section

Regarding surface

placement deviations, the following should be noted. The standard provides for

the following deviations in the placement of parts surfaces:

ü for planes – non-parallelism and

non-perpendicularity;

ü for cylindrical surfaces – misalignment,

radial and end runout;

ü for axes - misalignment of axes, deviation

from the correct placement of intersecting axes and passing axes.

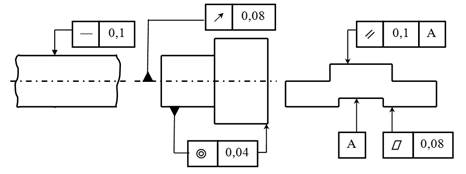

Limit

deviations and placement of surfaces are indicated on the drawings. On the

drawings, the sign and numerical value of the deviation are entered in a

rectangular frame divided into two or three parts (Fig. 6.3).

Fig.

6.3 – Designation of the limit deviations of the shape of details on the

drawings

In

the first part (on the left), the tolerance sign is indicated, in the second -

the numerical value of the limit deviation (in mm), and in the third - the

letter designation of the base or other surface. Bases are indicated by a

shaded equilateral triangle or a capital letter. The direction of the line

segment with the arrow must correspond to the direction of the deviation

measurement.

6.1.2 Methods of achieving processing accuracy

The

accuracy of processing on the machine is determined by the following factors:

1.

Quality of manufacturing and condition of machines and tools.

2.

Accuracy of tool installation.

3.

Deformation of the technological system.

4.

Inconsistency of the allowance on the surface of the part and inconstant

hardness.

5.

Temperature deformation in the technological system during the cutting process.

6.

Wear of the cutting tool.

7.

Deformation of the workpiece from the cutting force.

8.

Deformation of the workpiece as a result of stress redistribution during

removal of the allowance

9.

Qualification and discipline of the worker.

10.

Measurement error.

The

given accuracy of workpiece processing can be achieved using two fundamentally

different methods: trial runs and measurements; by the method of automatically

obtaining dimensions on adjusted machines.

The method of trial passages and

measurements

The

essence of the method is that a cutting tool is brought to the machining

surface of the workpiece mounted on the machine and a test chip is removed from

a short section of the workpiece. After that, the machine is stopped, a trial

measurement of the obtained size is made, the amount of its deviation from the

one indicated on the drawing is determined, and a correction is made to the

position of the tool, which is calculated by divisions of the limb of the

machine. Then, a trial processing ("stroke") of the workpiece section

is again carried out, a new trial measurement of the obtained size is made and,

if necessary, a new correction is made to the position of the tool. Thus, by

trial runs and measurements, the correct position of the tool relative to the

workpiece is established, which ensures the required size. After that, the

workpiece is processed along its entire length. When processing the next

workpiece, the entire tool installation procedure is repeated with trial

passages and measurements.

Marking

is often used in the method of trial passages and measurements. In this case,

thin lines are drawn on the surface of the workpiece with special tools

(drafting machines, rod-reamers, etc.), which show the outline of the future

part. During the subsequent processing, the worker tries to combine the

trajectory of the cutting blade of the tool with the line of marking the

workpiece and thereby ensure that the given shape of the processed surface is

obtained.

Advantages of the method: high accuracy of processing is

obtained on imprecise equipment; when processing a batch of small blanks, the

influence of the wear of the cutting tool on the accuracy of the dimensions

maintained during processing is excluded; in case of inaccurate preparation, it

allows you to correctly distribute the allowance and prevent the appearance of

defects; frees the worker from the need to manufacture a complex and expensive

device.

Disadvantages of the method: the dependence of processing accuracy

on the minimum thickness of the chip to be removed; the appearance of a defect

due to the fault of the worker; low productivity of processing, due to the

large amount of time spent on trial passages, measurements and marking; high

cost of processing the part due to low productivity in combination with high

qualification of the worker.

As a

result, this method is used in

single or small-batch production, research production, as well as in repair and

tool shops. In multi-series and mass grinding, because it allows compensating

for the wear of the abrasive tool.

The method of automatically obtaining

dimensions on adjusted machines

When

processing workpieces using this method, the machine is pre-adjusted in such a

way that the accuracy required from the workpiece is achieved automatically,

that is, almost regardless of the qualification and attention of the worker.

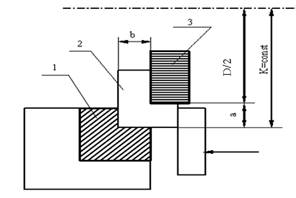

For example, when milling workpiece 2

to dimensions a and b, the table of the milling machine is

pre-set in height so that the support surface of the stationary jaw 1 of the vice is to the axis of rotation

of the milling cutter at a distance of K=D/2+a

(Fig. 6.4). At the same time, the side surface of the milling cutter 3 is moved away from the vertical

surface of the stationary sponge by a distance b.

|

Fig. 6.4 |

This preliminary adjustment of the

machine is carried out by the method of trial passages and measurements.

After such adjustment, the entire batch of blanks is processed without their

intermediates and without additional movements of the machine table in the

transverse and vertical directions. Just as in the process of processing, the

dimensions K and b remain unchanged, |

so the accuracy of the dimensions a and b remains the same for all workpieces processed on the machine with

this setup.

Advantages of the

method:

increasing the accuracy of processing and reducing defects; growth of labor

productivity; rational use of highly qualified workers; increasing production

efficiency.

The

method of automatically obtaining dimensions on adjusted machines is to a large

extent devoid of the disadvantages

inherent in the method of trial passages and measurements. With this

method, the task of ensuring processing accuracy is transferred from the

worker-operator to the adjuster, toolmaker and technologist.

The

method is widely used in modern

serial and mass production.

Each

of the considered methods of achieving the specified accuracy is definitely

accompanied by processing errors caused by various reasons of a systematic and

random nature. Accordingly, errors arising from these causes are divided into

systematic and random.