Laboratory lesson №2

Topic: Production and technological

process. The structure of the technological operation

Objective of the work - design of the technological process of

machining a stepped shaft; familiarization with the control system of the

machining process on a lathe.

Equipment, tools and materials:

1.

Working drawings of the part.

2. The lathe.

3.

Technological process of machining by transitions.

4.

Cutting tools: undercutting, boring, grooving and cutting lathe cutters.

5.

Measuring tools: caliper 0-175 (p/d = 0.01 mm), micrometer

0-50 (p/d = 0.01 mm).

6.

Reference books and tutorials.

Theoretical information

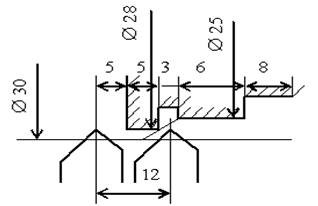

The development of the

process is carried out in a simplified form for one operation by transitions.

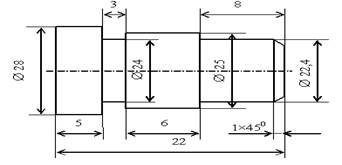

After selecting the workpiece,

the method of its fixture is determined, all transitions are outlined,

indicating the diameter of the machining and the actual length of each

transition, and the tool is selected. For example, for the part shown in Fig.

2.1, the technical process is presented in Table 2.1. The workpiece is mounted in a

three-jaw chuck according to its outer diameter.

Fig. 2.1 -

Drawing of the stepped shaft

Table 2.1

|

Transitions |

Contents of transitions |

Tool |

|

1 |

To

sharpen Æ25 in size 22 mm |

№1 passable |

|

2 |

To

sharpen Æ28 in size 12 mm |

№1 passable |

|

3 |

Chamfering

1×450 |

№1 passable |

|

4 |

To

sharpen Æ22,4 in size 8 mm |

№2 passable |

|

5 |

To

sharpen a groove 3 mm, Æ 24 mm |

№3 grooving |

|

6 |

Сut away in size 22 mm |

№4 cutting |

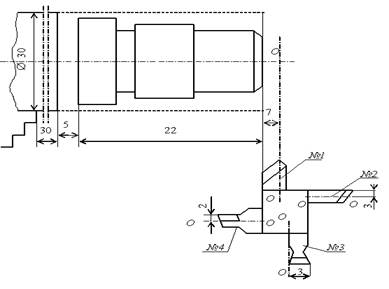

Draw a setup sketch as

shown in Fig. 2.2. The sketch must repeat the operational sketch of the part,

show the overhang of the workpiece

and chuck and the amount of longitudinal movement of the slide.

Fig. 2.2 - Setup diagram

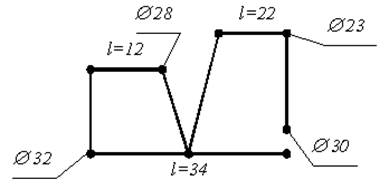

Development of a machine tool slide motion pattern (Fig. 2.3). The

length of the transverse and longitudinal feed paths of the caliper

is plotted on the diagram: for the transverse feed, the initial and final

diameters, and for the longitudinal feed, the distance travelled.

Fig. 2.3 - Schematic diagram of the caliper

movement

For the example under

consideration, the movements will be as follows: transverse feed of the slide

for turning Ø25

mm; longitudinal feed of the slide to a length of 22 mm (Fig. 2.4, a); withdrawal

of the slide in the transverse direction and its re-entry for turning Ø28

mm to the working length of the slide feed to a length of 12 mm (Fig. 2.4, b);

then withdrawal of the slide in the transverse direction by 2 mm and return in

the longitudinal direction to the starting position. The length of the

transverse and longitudinal feed paths of the caliper

is plotted on the diagram: for the transverse feed, the initial and final

diameters, and for the longitudinal feed, the distance travelled.

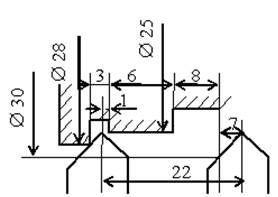

a

b

Fig. 2.4 - Diagram of the tool position and end of the

machining pass:

a - Ø25

mm, b - Ø28

mm

The procedure for performing the work

1. Development

of the technological process of the operation by transitions.

2. Sketch

of the workpiece

and setup.

3. Drawing

up a diagram of the caliper movement.

4. Setting

the cutting modes.

5. Performing

work and checking the dimensions obtained in accordance with the task.

Contents of the work report

1. Title

of the work.

2. Purpose

of the work.

3. Name

of the machine, model, technical characteristics.

4.

Cutting tool, material.

5. Data

on measuring instruments: name, price of division.

6. Cutting

modes.

7. Sketch

of the workpiece

and parts, material.

8. Technological

process of machining a part in one operation by transitions.

9. Scheme

of adjustment.

10.

The scheme of movement of the caliper.

11.

Conclusions.